23

Instructional Booklet

IB02102006E

Effective May 2011

Type MVS (previously WLI)

metal-enclosed switchgear—

4.76 kV, 15.0 kV, 27.0 kV, and 38.0 kV

eaton corporation

www.eaton.com

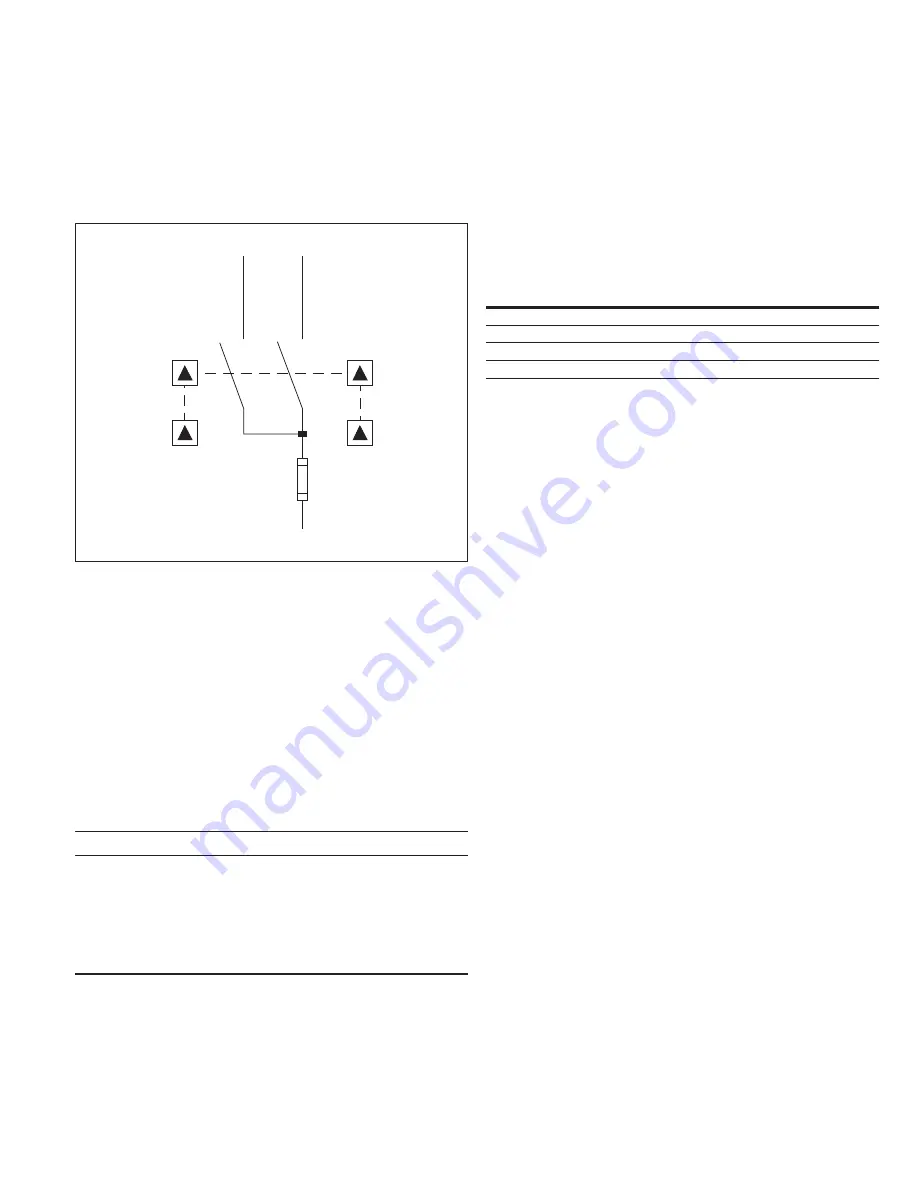

Duplex switchgear configuration

When supplied, the duplex configuration consists of two MVS

switches feeding a common bus, which in turn is connected to the

set of fuses in one of the switch sections . This arrangement allows

the selection of either of two incoming lines to feed a load

(see

Figure 31

) .

Figure 31. Duplex Selective Switch Configuration

This arrangement is supplied with key interlocking for safe opera-

tion . Key interlocking normally consists of a lock on each switch to

lock the switch in the “Open” position and a lock on each door to

lock each door closed . Each lock is keyed alike . Only one key is to

be available to operating personnel . Because the key is retained in

its lock when a switch is “Closed” or when a door is opened, two

things are ensured:

1.

Only one switch may be closed at a time . This prevents

paralleling of incoming lines and prevents opening either

enclosure door .

2.

Both switches are locked in the open position to unlock either

main door . This prevents access to the common bus or fuses or

being able to “Close” either switch .

CAUTION

HAzARD OF ELECTRICAL SHOCK OR BURN. FAILURE TO IMPLEMENT

AND USE THE KEy INTERLOCKING SySTEM PROVIDED WILL EXPOSE

PERSONNEL TO DANGEROUS VOLTAGES.

IMPLEMENT AND USE THE KEy INTERLOCKING SySTEM PROVIDED.

USE ONLy THE NUMBER OF KEyS REQUIRED FOR CORRECT OPERATION.

ALL EXTRA KEyS MUST BE EITHER DESTROyED OR MADE INACCESSIBLE

TO OPERATING PERSONNEL.

Line

LO

LO

LD

LD

Load

Line

Motor operation

Motor-operated MVS switch

The motor-operated MVS switch is essentially a standard manually

operated switch with a motor driven linear actuator connected to

the switch mechanism . Because all basic switch parts are identical

to those of the standard, manually operated switch, sections of this

instruction book pertaining to installation, inspection before startup,

maintenance, and parts replacement also apply to the motor

operated switch .

Table 6. MVS Switch Motor Operator Current Requirements

nominal Voltage

e/r amperes

120 Vac

3.0

24 Vdc

7.0

48 Vdc

3.5

125 Vdc

1.5

Time to open or close an MVS switch with an integral motor

operator is about 5 seconds for the AC versions and about

10 seconds for the DC versions .

Receiving and startup

For MVS switches, units are shipped with the linear actuator

installed .

Electrical operation

The preferred voltage for the linear actuator to operate is 120 Vac,

and control power is normally supplied by the customer . See the job

drawings for an electrical schematic diagram and wiring diagram of

the motor operator circuitry to determine the actual operating

voltage and power source .

Safety interlocking

For an MVS motor-operated switch, safety interlocking is based upon

a key interlock system . The switch mechanism key interlock must

have an integral electrical switch . Extending the interlock bolt would

mechanically lock the MVS switch in the “Open” position, would

open the electrical control power circuit for the motor operator, and

would release the key . With the key, a person can then unlock the

key interlock on the switch enclosure door .

This scheme prevents closing the switch with the door open as well

as prevents opening of the enclosure door with the switch closed .