EATON

Installation & Maintenance Instructions

TM396 – XF-XP-XT LW UL ISS.A

18 |

P a g e

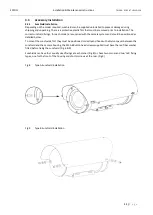

4.0 Maintenance

Please read and be familiar with the instructions in this manual before servicing any parts of these

camera units.

Regular maintenance to the X Series of camera units is important to safeguard their use in harsh and

hazardous environments. Recommended inspection interval: 6 Months.

Inspect the unit regularly every six months to ensure trouble free operation and extended product life.

Due to the rugged construction of the unit, little or no maintenance should be required.

It is recommended that, where the unit is exposed to regularly extreme weather conditions, the ‘O’ ring

weather seals in the removable window covers, removable enclosure covers, and base junction box are

replaced every five years.

Fixings and fastenings should be checked for tightness and integrity at regular intervals.

All cable entries and cables should be checked for integrity at regular intervals.

Extremely harsh environments may require more frequent inspection and maintenance checks.

Therefore, the end user or installer shall ensure that this equipment is protected against external

influences which could adversely affect the explosion protection or contact the manufacturer if in doubt

of the suitability of this equipment in the environment in which it is to be installed.

At every Inspection carry out the following:

•

Clean the exterior of the unit.

•

Check the ‘O’ ring weather seals and replace if necessary.

•

Check, and if necessary, replace the washer nozzle.

•

Check, and if necessary, replace the window wiper blade assembly.

•

Use only Eaton approved spare parts.

4.1

Corrosion Protection

All external metal components are produced from 316L Stainless Steel, however, if the units are not

correctly maintained, handled and cleaned there is the possibility of mild discolouration due to normal

oxidation.

If ferrous metal equipment is used when handling the units, small ferrous deposits could be left on the

stainless steel, or if ferrous metal particles come to rest upon the units from nearby works, this can cause

accelerated corrosion of the ferrous deposits and discolour the units by normal oxidation. In the event of

ferrous deposits, the units should be cleaned immediately following EATON guidelines.

In atmospheres that have high levels of corrosive particles, the units should be cleaned every 3 to 4 months

using only EATON recommended cleaning products and procedures. (contact EATON for details)

EATON TAKES NO RESPONSIBILITY FOR OXIDISATION DUE TO A FAILURE TO COMPLY

WITH THE CORRECT CLEANING PROCEDURES.

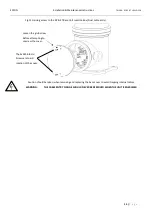

5.0 Labelling & Marking

The certification and rating labels are etched on 316 stainless steel and fixed to the units using stainless

steel rivets. The contents of the label will be in ENGLISH. (And FRENCH for CSA).

The label shows:

A.

Name of Manufacturer

B.

Model Type

C.

Operating Voltage

D.

Area Classification

E.

Serial Number,

F.

UL File Number