Chapter 6—Installation Requirements

DG1 Series VFD

MN040002EN—March 2014

www.eaton.com

27

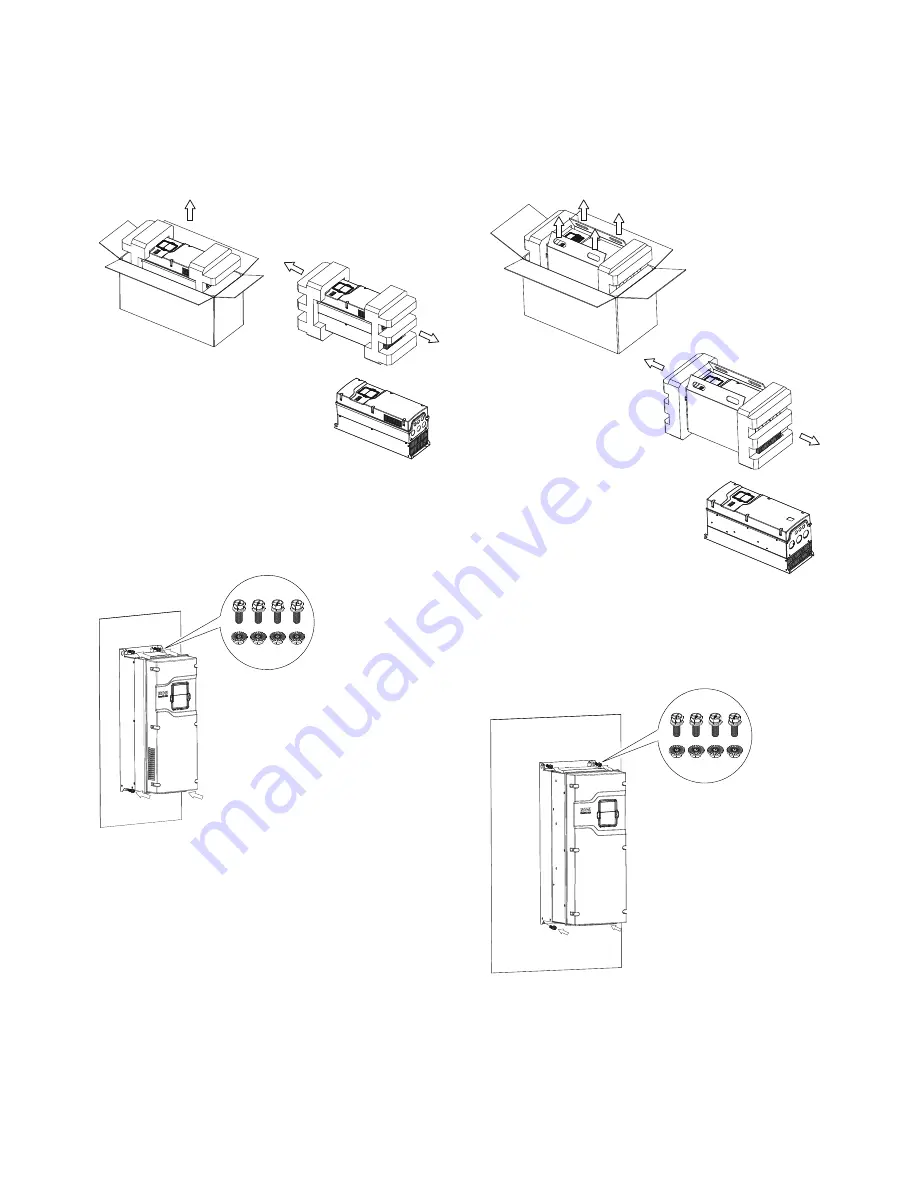

FR3 Mounting Instructions

Step 1:

Lift the drive out of the carton. Remove the

packaging.

Step 2:

Attach the drive to the mounting plate with four

M6x15 or 1/4 inch screws and four M6 or 1/4 inch

nuts. The opening dimensions on the mounting

plate should follow required dimensions (refer to

the drive mounting template printed on the outside

carton).

FR4 Mounting Instructions

Step 1:

Lift the drive out of the carton with the cardboard.

Remove the packaging.

Step 2:

Attach the drive to the mounting plate with four

M8x15 or 3/8 inch screws and four M8 or 3/8 inch

nuts. The opening dimensions on the mounting

plate should follow required dimensions (refer to

the drive mounting template printed on the outside

carton).

Screw: Four M6x15

or 1/4 inch

Nut: Four M6

or 1/4 inch

Screw: Four M8x15

or 3/8 inch

Nut: Four M8

or 3/8 inch

Summary of Contents for PowerXL DG1-32011FB-C21C

Page 1: ...PowerXL DG1 Series VFD Installation Manual Effective March 2014 New Information ...

Page 2: ......

Page 83: ......