UPS INSTALLATION PLAN AND UNPACKING

Eaton

Power Xpert 9395P-600 (380V-600V) UPS Installation and Operation Manual

S

P-164000710 Rev 1

www.eaton.com/powerquality

3-30

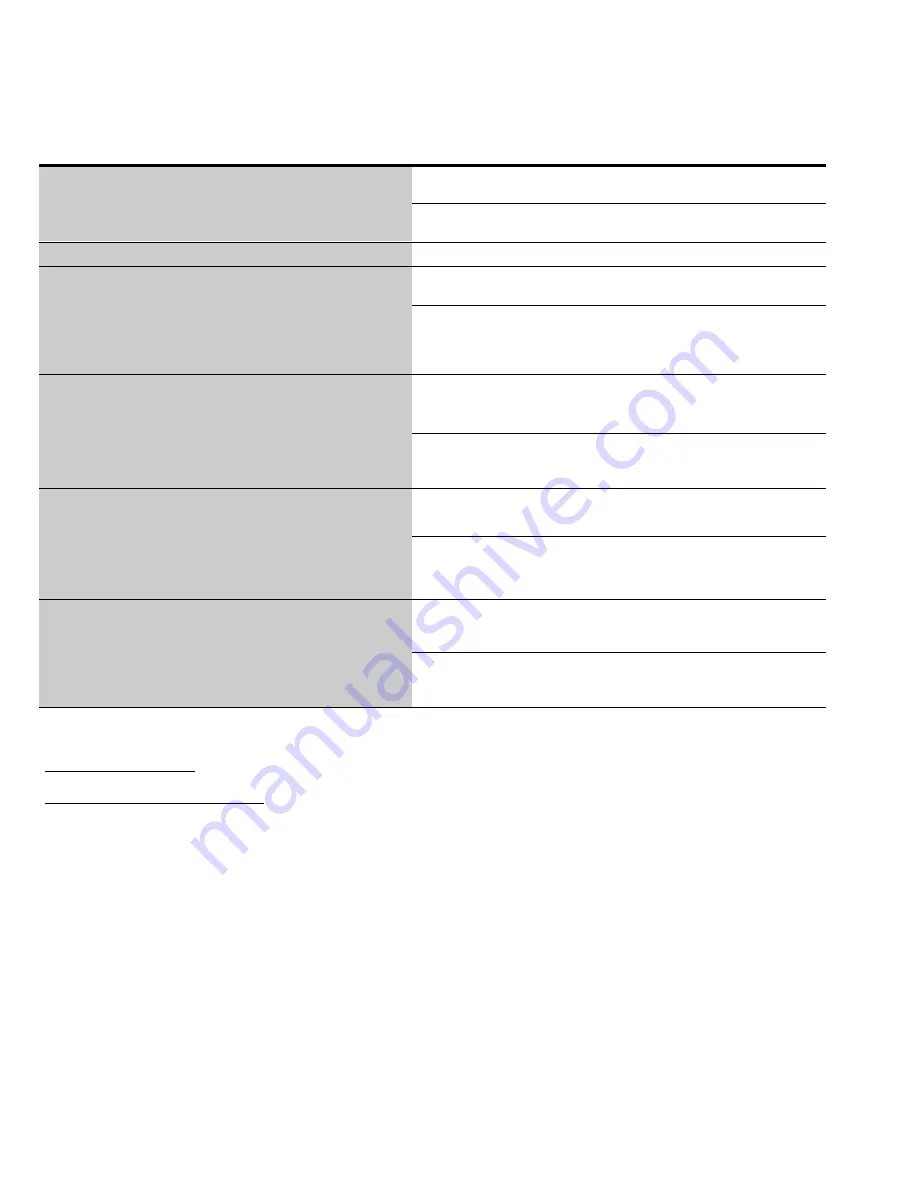

Table 3‐16. 380V Input/Output Ratings and External Wiring Recommendations for the One/Two/Three UPM Common Battery

Basic Unit Rating

Units

Rating

50/60 Hz

Rating

50/60 Hz

Rating

50/60 Hz

Rating

50/60 Hz

Rating

50/60 Hz

kVA

kW

300

300

400

400

450

450

500

500

550

550

Input and Output Voltage

Volts

380/380

380/380

380/380

380/380

380/380

AC Input to UPS Rectifier (0.98 Minimum pF)

Full load current plus battery recharge current

(3) Phases, (1) Ground

Minimum Conductor Size

Number per Phase

A

Amps

545

727

800

909

960

AWG or

kcmil

(each)

300

(3)

500

(3)

500

(3)

500

(4)

500

(5)

AC Input to UPS Bypass (Five Wire)

Full Load Current

(3) Phases, (1) Neutral, (1) Ground

B

Amps

456

608

684

760

836

Minimum Conductor Size

Number per Phase

AWG or

kcmil

(each)

400

(2)

350

(3)

500

(3)

500

(3)

500

(4)

DC Input from Battery Disconnect to UPS

(1) Positive, (1) Negative

Minimum Conductor Size

Number per Pole

(1) Positive, (1) Negative

C

Total

Amps

658

877

987

1096

1206

AWG or

kcmil

(each)

500

(2)

500

(3)

500

(3)

500

(4)

500

(5)

AC Output to Critical Load (Five Wire)

Full Load Current

(3) Phases, (1) Neutral, (1) Ground

D

Amps

456

608

684

760

836

Minimum Conductor Size

Number per Phase

AWG or

kcmil

(each)

400

(2)

350

(3)

500

(3)

500

(3)

500

(4)

NOTE

Callout letters

A

,

B

,

C

, and

D

map to common battery systems. Callout letters

A

,

C

, and

D

map to separate battery systems. See Figure 6‐5 on

page 6-10 through Figure 6‐15 on page 6-20.

NOTE

Bypass wiring data is not applicable to IOM configurations.

Battery Conductor Sizing:

Eaton strongly recommends using the specified DC conductor size and quantity shown above for optimum system

performance and battery run time.

Battery Cable Routing Requirements

Conduit applications:

* Each conduit must have a Positive, Negative, and Ground conductor.

* There must be an equal number of positive and negative conductors in a single conduit. Only one ground conductor is required in each

conduit.

Raceway applications:

* Positive and negative battery cables must be run side by side in the raceway in an alternating pattern (+ - + - + - + -).

* There must be a ground cable running in the raceway with the battery cables

.