12

5 Installation

The floodlight is suitable for special operating conditions such as on

offshore platforms or in chemical or pharmaceutical plants.

The adding of further modules or the removal of modules from the modular

PXLED floodlight by the operator is not permitted.

The intended use does not include applications with

high-charging processes. Those could be for example high-voltage

sources generating ion-winds or pneumatically transported dust

atmospheres in touch with the enclosure.

X

ATEX - IEC

The floodlight has to be protected against electrostatic

discharges.

The data as per point 3 and 4 shall be taken into account with the use.

Applications other than those described are not permitted

without Cooper Crouse-Hinds’s / EATON’s prior written consent.

The instructions stated in section 7 of the operating instructions

shall be observed during operation.

The user alone is responsible for the appropriate use of this

junction box in consideration of the basic conditions existing at the

plant (see technical data).

The product is protected by patents. For more information, please contact

your local Cooper Crouse-Hinds / EATON representative.

6 Installation

For the mounting and operation, the respective national regulations as

well as the general rules of engineering will have to be observed

(IEC/EN 60079-14).

The improper installation and operation of floodlight may result in

the explosion protection and invalidation of the guarantee.

Transport and storage only in original packaging in a closed and dry room!

Observe for any cracks or damage in housing and glass during installation

or reparation! Don´t damage the fire-finish of the glass adquired during

moulding (abrasions, sanding, etc.) that can weaken their mechanical

functions.

6.1 Montage

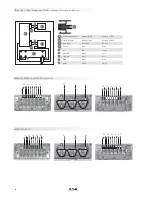

See fig. 1 ... 7

The flood lights can be mounted without opening their enclosure.

If cable entries are used from the top, mount only in dry rooms or attach

where protected from moisture.

!

For wall assembly Cable entry from below.

The flood light may rest evenly only at the respective fastening points.

Mounting surfaces, e.g. walls, ceilings or parts of frameworks, have to be

flat.

The chosen screw shall match the fastening hole (see dimensional

drawing) and it must not damage the hole (e. g. use of a washer).

If the screws are overtightened, the apparatus can be damaged.

6.2

Opening flood light connection cabinet

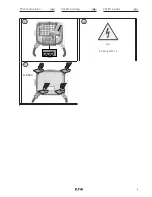

See fig 6

Warning against electric shock.

Ensure and take suitable precautions before opening the housing.

Warning of explosion.

Before opening the housing to make sure that no explosive atmos-

phere environment.

Additional mounting material see CCH / EATON catalogue.

6.2.1 Cable entries

The cables and cable entries must correspond with the minimum

temperature resistance depending on the lamp (see technical data).

Connecting cable exposed to strain must be relieved by suitable

measures.

When assembling the cable entries for the mains connection, please observe

the manufacturer’s specifications for the used seals and cable entries!

– Introduce the cable through the Ex cable entry.

When using plastic KLEs use

sealing inserts 1,2 and 3 for cables from 8 to 10 mm Ø,

sealing inserts 1 and 2 for cables from 10 to 13 mm Ø

and sealing insert 1 for cables from 13.5 to 17.5 mm Ø.

Pay attention to the proper fit of the remaining sealing insert in the

cable gland.

For metal KLE see additional KLE instruction.

Unused cable entries have to be closed by a correspondante certified

blanking plug.

The cable entries and sealing stoppers must be approved for the lamp’s

type of protection!

In order to ensure the required minimum protection category, the cable

glands shall be tightened down (test torque) .

Overtightening might impair the protection category.

6.2.2 Electrical connection

The electrical connection of the equipment must be performed

by qualified electricians (IEC/EN 60079-14).

See wiring diagram and fig. 8 and 9.

All screws and/or nuts of the connection terminals, including those not in

use, shall be tightened securely.

To maintain the explosion protection, the connection of conductors

shall be carried out with special care.

The minimum and maximum conductor cross sections shall be taken

in account (see technical data).

The respective regulations shall be taken into account when connecting

the correctly stripped connection conductors of the cables.

Only carry out insulation measurements between PE and the external

conductor L1 (L, L2, L3) as well as between PE and N.

– measuring voltage: max. 1 kV DC

– measuring current: max. 10 mA

Explosion protected flood light type: PXLED

GB

Summary of Contents for PXLED

Page 18: ...18 Notizen Notes Remarques ...

Page 19: ...19 Notizen Notes Remarques ...