60

Instructions for Installation, Operation and

Maintenance of Magnum SB Insulated Case

Low Voltage Power Circuit Breakers

EATON CORPORATION

www.eaton.com

Instructional Leaflet

IB2C12063H03

Effective March 2012

What To Inspect

What to inspect and to what extent is dictated by the nature of

the maintenance function . Routine inspections require one type

of observation . Inspections following a known high level fault

require more detailed inspections .

A drawout type circuit breaker should first be withdrawn from

its compartment onto the compatment’s extension rails . When

the inspection is complete, the circuit breaker can be levered

to the TEST position to check the electrical operations of the

circuit breaker .

During the levering out and levering in of the circuit breaker, be

aware for any signs that would indicate that this process is not

working properly .

During the inspection of fixed type circuit breakers, bus sys-

tems supplying the fixed circuit breakers should be de-ener-

gized for convenience and safety .

For functional testing of the trip unit, refer to the separate

detailed instruction book dedicated to the trip unit .

Once the circuit breaker has been cleaned as described on

the previous page, visually inspect it for any signs of damage,

missing or loose parts and unusual wear . Be especially alert for

foreign matter that must be removed . On drawout circuit break-

ers, inspect the primary disconnect finger clusters for signs

of wear and erosion . Make appropriate corrections to anything

found out of order .

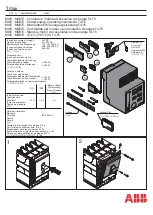

Table 13. Field Service Tool List

Tool Description

Where Used

10 mm 1/4-inch drive socket

All 6 mm bolts

1/4-inch universal

Mechanism mounting

1/4-inch 6-inch drive extension

As needed

10 mm combination wrench

Primary disconnects

1/4-inch drive ratchet

As needed

3/8-inch drive ratchet

As needed

3/8-inch 17 mm socket

Load conductors

3/8-inch 6-inch extension

Levering-in

17 mm combination wrench

Load conductors

3/8 drive 8 mm or 5/16 long ball driver

Line conductor/arc runner

AMP extraction tool #305183

Secondary contacts

AMP extraction tool #455822-2

Current sensors/shunt trip

#3 Posi-drive screwdriver

Levering-in

#2 Philips screwdriver

As needed

#1 Philips screwdriver

As needed

Long (8-inch) 3/16-inch straight blade

screwdriver

Motor operator installation

7/16-inch combination or adj. wrench

Motor operator stand-off installation

1/4-inch straight blade screwdriver

Rating plug

Pocket size, straight blade screwdriver

Trip unit setting

Eaton test kit and adapter

Digitrip trip unit

It will also be necessary to have a full compliment of standard

field service tools available including, pliers, cutters, soldering

tools, multi-meter, and so on .

Functional Field Testing

NOTICE

BEFORE DOING ANY WORK ON DRAWOUT TYPE CIRCUIT BREAKERS,

MAKE SURE THE BREAKER IS LEVERED OUT TO THE TEST OR

DISCONNECT POSITION. DURING THE LEVERING OUT AND LEVERING

IN OF THE CIRCUIT BREAKER, BE AWARE OF ANY SIGNS THAT

WOULD INDICATE THAT THE LEVERING PROCESS IS NOT WORKING

PROPERLY. IF WORKING ON A FIXED CIRCUIT BREAKER, BUS

SYSTEMS SHOULD BE DE-ENERGIZED FOR CONVENIENCE AND

SAFETY. THE CIRCUIT BREAKER SHOULD BE SWITCHED TO THE OFF

POSITION AND THE MECHANISM SPRINGS DISCHARGED.

Eaton Cutler-Hammer recommends that the following func-

tional tests be performed on Magnum circuit breakers as part

of any maintenance procedure . The circuit breaker should be

removed from service and Cutler-Hammer notified if the circuit

breaker fails to perform any of these tests successfully . Please

be prepared to provide the number of operations the circuit

breaker has to date as well as the following nameplate informa-

tion (

Figure 88

):

A . Low voltage power circuit breaker family name

B . Breaker family designation number

C . Breaker frame size in amperes

D . Interrupting capacity rating

E . Factory Equipped Accessories

Figure 88. SB Nameplate