SVX9000 Drives

MN04003009E—November 2011 www.eaton.com

2

STEP 1 (Continue

d

)

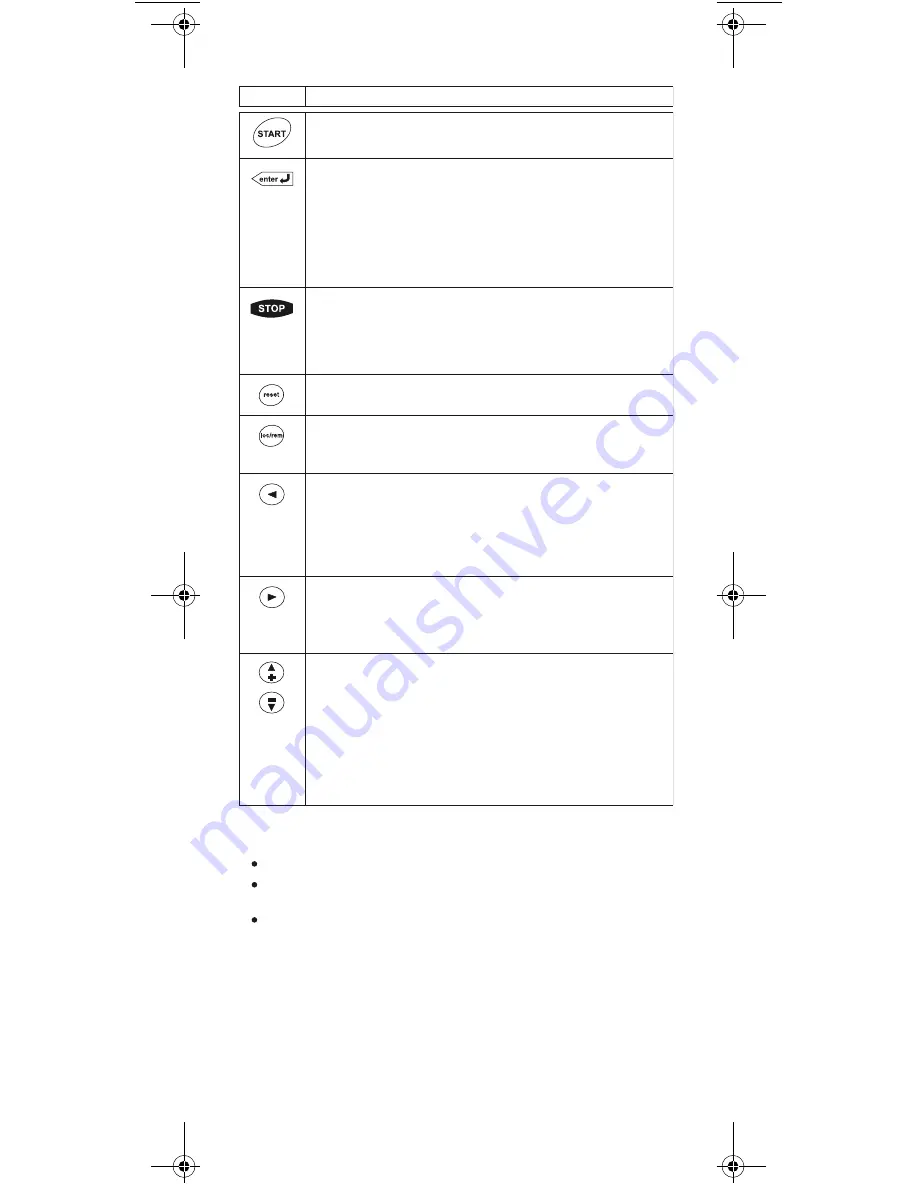

Navigation Buttons

Menu Navigation

Navigation Tips

To navigate within one level of a menu, use the up and down arrows.

To move deeper into the menu structure and back out, use the right

and left arrows.

To edit a parameter, navigate to show that parameter’s value, and press

the right arrow button to enter the edit mode. In edit mode, the

parameter value will flash.

Button

Description

Start

This button operates as the START button for normal operation when

the “Keypad” is selected as the active control.

Enter

This button is used in the parameter edit mode to save the parameter

setting and move to the next parameter …

•

to reset the Fault History if pressed while in the “Fault History”

menu.

•

to confirm the acceptance of a change.

•

to change a virtual button status while in the “Button” menu.

•

to confirm the start-up list at the end of the Start-Up Wizard.

•

when the “Operate” menu is active, to exit the “Operate” submenu.

Stop

This button has two integrated operations. The button operates as

STOP button during normal operation …

•

motor STOP from the keypad, which is always active unless

disabled by the “StopButtonActive” parameter.

•

used to reset the active faults.

Reset

Resets the active faults.

Local / Remote

Switches between LOCAL and REMOTE control for start, speed

reference and reverse functions. The control locations corresponding

to local and remote can be selected within an application.

Left Arrow

•

navigation button, movement to left.

•

in parameter edit mode, exits mode, backs up one step.

•

cancels edited parameter (exit from a parameter edit mode).

•

When in “Operate” menu will move backward through menu.

•

At end of “Start-Up Wizard”, repeats the “Start-Up Wizard”

setup menu.

Right Arrow

•

navigation button, movement to right.

•

enter parameter group mode.

•

enter parameter mode from group mode.

•

When in “Operate” menu will move forward through menu.

Up an

d

Down Arrows

•

move either up or down a menu list to select the desired menu item.

•

editing a parameter/password, while the active digit/character is

scrolled.

•

increase/decrease the reference value of the selected parameter.

•

in the “Operate” menu, will cause the display of the active reference

source and value and allow its change if the keypad is the active

reference source. Used to set the password (if defined) when

leaving the “Operate” menu.

•

scroll through the “Active Faults” menu when the SVX9000 is

stopped.

MN04003009E.fm Page 2 Wednesday, November 9, 2011 8:47 AM

Summary of Contents for SVX9000 Series

Page 19: ......