5

Service

The following instructions describe the

complete rebuilding of your Vickers TE,

TF or TL cylinder.

Refer to Figure 4 exploded view.

Warning

Before breaking a circuit connection,

make certain that power is off and

system pressure has been released.

Lower all vertical cylinders, discharge

accumulators, and block any load

whose movement could generate

pressure. Plug all removed units and

cap all lines to prevent the entry of dirt

into the system.

Required Tools

Spanner wrench

Adjustable wrench

Soft brass tool

Thin tool (like a metal ruler)

Copper padded vice

Rubber mallet

Torque wrench

Replacing Rod Seals

1. Once the cylinder is removed from

service, fully retract the piston rod

and remove all port connections.

Drain any hydraulic fluid by manually

cycling the cylinder. Large cylinders

can be carefully cycled with air

pressure.

2. The Quick Change rod cartridge

allows rod seal replacement without

disturbing the tie rods. Remove any

burrs from the wrench flat area of the

piston rod. Place the cylinder in a vice,

rod end up if possible. Remove the

rod bearing retainer plate by removing

the retainer screws. The retainer may

be round, square or rectangular.

Round retainers that are recessed into

the head have a pry groove on the

O.D. or two tapped holes to aid

removal.

3. Remove the rod seals on smaller

cylinders by placing your thumb over

the rod end port and giving a quick

pull on the piston rod. Use low

pressure air in the rod end port for

larger cylinders. Leave the bearing

on the rod to catch the seals as they

leave the seal cavity. Note the

position of the male seal adaptor

relative to the bearing and the seals.

Leave the male seal adapter in place

if in the bottom of the seal cavity, to

support the piston rod while

performing the remaining

disassembly.

4. Remove the elastomer rod wiper or

rod scraper retainer from the rod

bearing. Remove the rod scrapers if

applicable.

5. For metallic scrapers, stack the new

scraper rings so that the slots are

staggered. Lightly lubricate the new

wiper or retainer and push it into the

bearing groove with a soft brass tool.

6. Lightly lubricate the new rod seals

and replace, one at a time, by

leading the outside sealing edge with

a soft brass tool as each seal is

inserted in the cavity. Be careful not

to damage the seals when placing

them over the piston rod.

7. Carefully replace the bearing on the

rod. Slide the retainer plate into

position. Replace the retainer

screws, and tighten in a cross

sequence pattern. Torque to values

shown in Table 2 below.

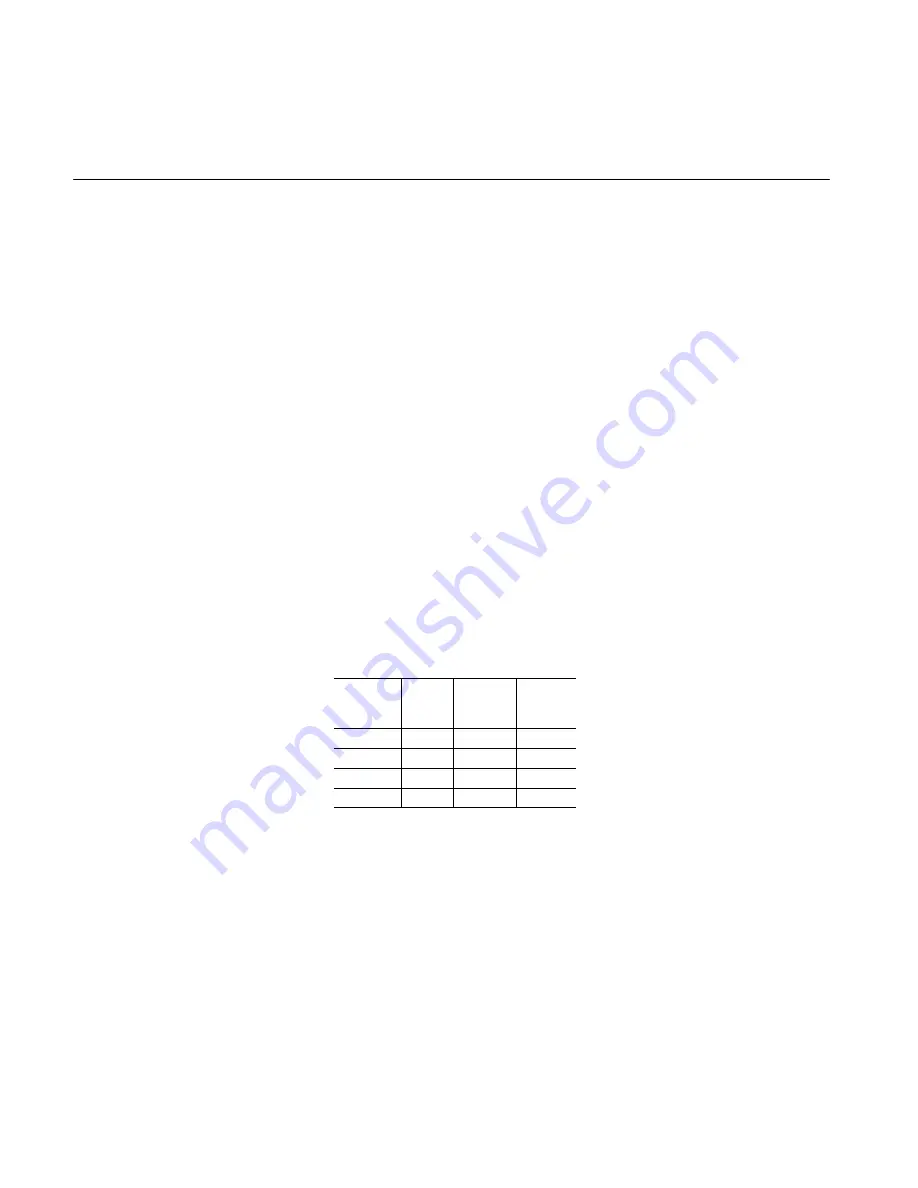

Retainer Screw Torque

Retainer

Screw

Size

Screw

Part #

6893

Screw

Part #

6894

Rec.

Torque

(ft-lbs)

1

/

4

- 28

-1 -2

-1 -2 -3

7

1

/

4

- 28

-1, -2

-1, -2, -3

7

5

/

16

- 24

-3 -4

-4 -5

12

5

/

16

- 24

-3, -4

-4, -5

12

3

/

8

- 24

-5

-6 -7

22

3

/

8

- 24

-5

-6, -7

22

1

/

2

- 20

-6, -7

-8, -9

50

Table 2.

Complete Rebuild

1. Repeat steps 1, 2, 3, 4 and 5 in

Replacing rod seals section.

2. Remove the tie rod nuts, loosening

in a cross sequence pattern.

Carefully remove the cap or head

from the tie rods and inspect for

damage or signs of contamination.

3. Remove the cylinder body from the

head/cap. Slide the piston rod

assembly out of the cylinder body. It

is not necessary to remove the tie

rods if threaded into a tapped head

or cap for servicing, unless the

tapped head or cap is mechanically

damaged.

4. The piston does not have to be

removed from the rod for normal

piston seal replacement. Cast iron

piston rings may be removed by

inserting a thin tool under the joint

and running it around the

circumference of the piston.

5. Remove the nonmetallic wear band

which simply snaps into the groove

on the piston’s outer diameter, if

applicable.

6. If piston removal from the rod is

required, slide the piston rod

assembly out of the cylinder body.

Clamp the rod securely in a copper

padded vice that will protect the rod

finish. If a locknut holds the piston to

the rod, loosen and remove locknut.

7. If no locknut is present, heat the

piston to approximately 350

_

F with a

torch or in an oven to break the

anaerobic adhesive. Insert a

spanner wrench in the drilled holes

on the piston face and break the seal

by rapping the wrench with a rubber

mallet, rotating the piston in a

counterclockwise direction.

CAUTION

THE PISTON IS HOT!

8. Unscrew the piston and set it aside.

9. Remove the cushion collar from the

rod, if the cylinder is cushioned on

the head end. Let the rod cool before

re-assembly.

10. Snugly secure the rod into the vice.

Replace the cushion collar on the

rod (if required). Thoroughly clean all

metallic surfaces with a

non-petroleum based cleaner and a

wire brush, if necessary.

11. Apply anaerobic adhesive near the

rod shoulder (or collar) on the rod

threads and on the piston I.D.

threads.

NOTE

Be sure to follow the adhesive

manufacturer’s

recommendations regarding

surface preparation, priming

requirements, proper adhesive

for the thread size, and cure time

prior to pressurization. Failure to

do so could result in improper

sealing and retention.