7

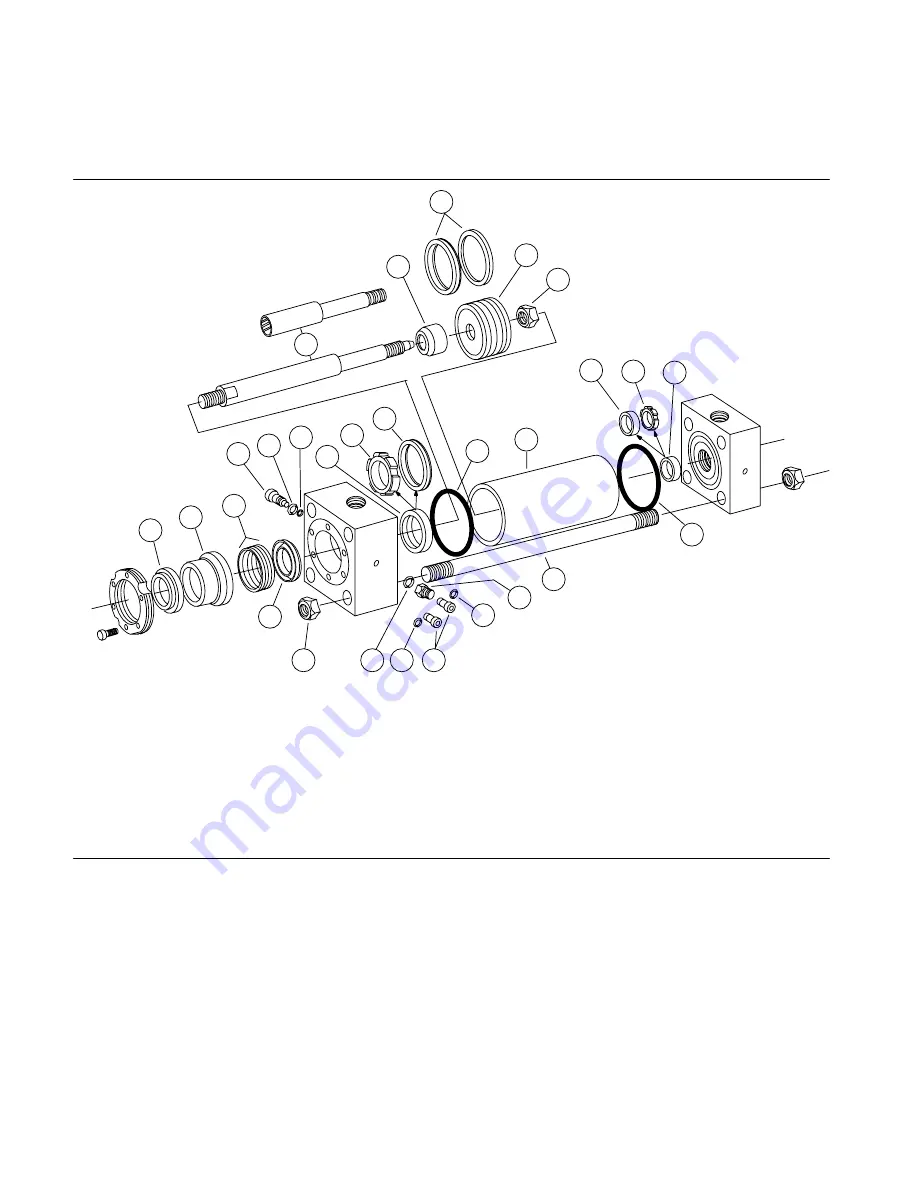

Exploded view

Figure 4.

1

10

13

12

11

23

26

25

2

3

5

4

7

8

12

20

21

9

6

24

22

18

19

17

15

14

15

16

Maintenance

Inspection

All parts in the unit must be kept clean

during the overhaul. Handle each part with

care and always work in a clean area.

Periodic inspection of the fluid condition

and tube or piping connections can save

time consuming breakdowns and

unnecessary parts replacement. The

following should be checked regularly:

1. All hydraulic connections must be

kept tight. A loose connection in a

pressure line will permit the fluid to

leak out. If the fluid level becomes so

low as to uncover the inlet pipe

opening in the reservoir, extensive

damage to the pump can result. In

suction or return lines, loose

connections permit air to be drawn

into the system resulting in noisy

and/or erratic operation.

2. Clean fluid is the best insurance for

long service life. Therefore, the

reservoir should be checked

periodically for dirt or other

contaminants. If the fluid becomes

contaminated, the system should be

drained and the reservoir cleaned

before new fluid is added.

3. Filter elements also should be

checked and replaced periodically. A

clogged filter element results in a

higher pressure drop. This can force

particles through the filter which would

ordinarily be trapped, or can cause the

by-pass to open, resulting in a partial

or complete loss of filtration.

4. Air bubbles in the reservoir can ruin

the pump and other components. If

bubbles are seen, locate the source

of the air and seal the leak.