10

Torque Motor Coil

Location

Color Code Versus

Connector Pin

Location

Red

Coded

Coil “A”

A

B

Coil “B”

Coil located next to the

armature connection nut

D

C

Table 4. Coil location and wiring code to male electrical connec-

tor (Item 4, Figure 3).

7. Remove a

1

/

4

inch of insulation from the ends of the

wires, then install a short piece of spaghetti sleeve over each

wire end and slide back on the wire. Position the wire ends up

and slide a new gasket (5) over the wires. Tin each wire end

with solder, then insert wires one at a time into the proper pin

of connector (4) and solder. Slide the sleeve over the pin after

solder has cooled.

Coil resistance,

ohms/wire code

Series

aiding

Parallel

Differential

40 / Yellow

150 ma

300 ma

N/A

280 / White

50 ma

100 ma

100 ma

2200 / Blue

20 ma

40 ma

40 ma

5300 / Black

12.5 ma

25 ma

25 ma

Table 5. Input current required for max. armature deflection of

0.020 inch.

8. Assemble connector to the body with four screws. (3).

NOTE

Cover (7), screws (8), and washers (9) will be

installed following test and calibration, Section VII.

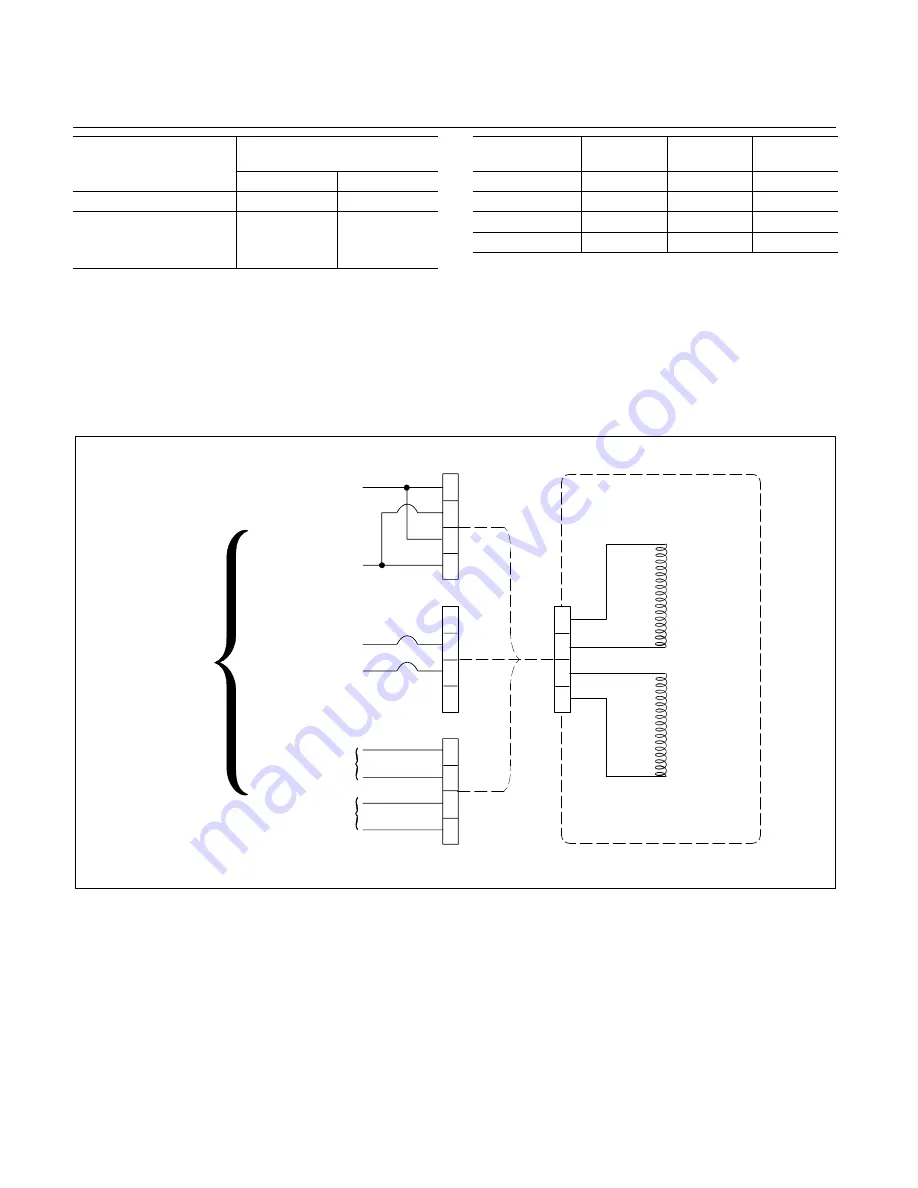

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

TORQUE MOTOR

MALE CONNECTOR

A

– Red

B

– Coded

C

– Coded

D

– Red

Coil “B”

(Next to

armature

nut)

CABLE

+

–

–

+

–

+

+

–

PARALLEL

CONNECTION

SERIES

AIDING

CONNECTION

DIFFERENTIAL

CONNECTOR

POWER

SUPPLY

Polarity for

movement of

armature nut

in direction

of arrow

stamped on

torque motor.

NOTE: Reversal

of supply will

reverse

movement of

armature.

Figure 5. Schematic diagram of possible wiring connections to a Torque Motor.