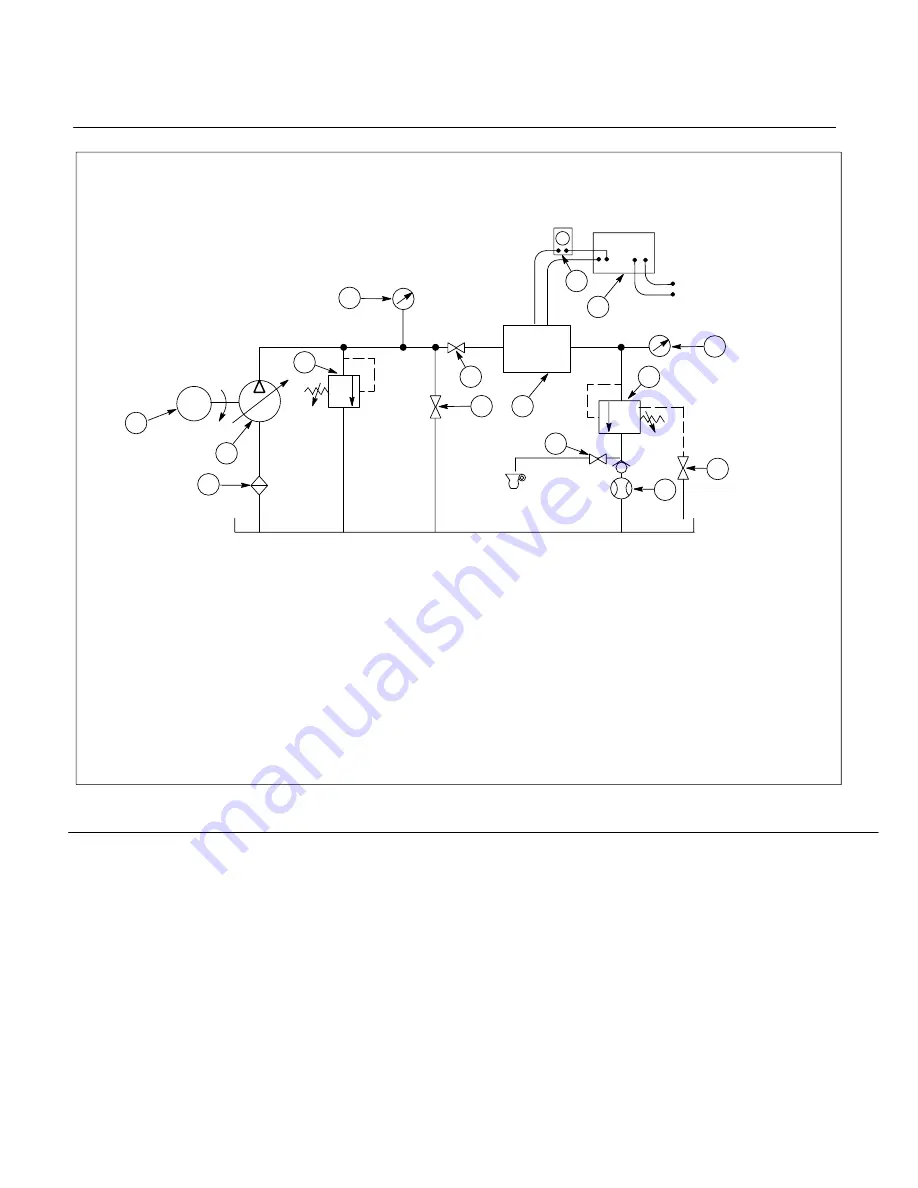

12

2

Beaker

1.

Globe valve

2.

Test stand relief valve

3.

Inlet filter

4.

Variable delivery pump

5.

Pressure gage (0–3500 psi)

6.

Globe valve

7.

Valve under test

8. Ammeter (0–500 mA)

9. Power supply Vickers 631995 or

equivalent. Must be capable of

delivering 0–300 mA DC to a

20 OHM inductive load.

10. Pressure gage (0–3000 psi)

11. Load relief valve

12. Globe valve

13. Flow meter

14. Electric drive motor approximately

10 hp for 5 gpm @3000 psi

15.

1

/2

Globe valve

16. 35 psi check valve

Figure 6. Test stand for FCGT-02-*-11 valve

M

6 7

2 1

Printed in U.S.A.

11

14

4

3

5

1

6

7

8

9

10

12

13

15

0-500mA

Meter

117 VAC 60

Power

Source

Gage

0–3000

Pump

System

Relief

Valve

Gage

0–3500

IN

OUT

Vent