9

3. Inspect metering spool (12) and hydrostat (20) for

excessive wear, galling, erosion, and burrs. Remove burrs

with an India stone. If either of the spools are defective,

check body (30) bores for similar defects. Replace defective

parts.

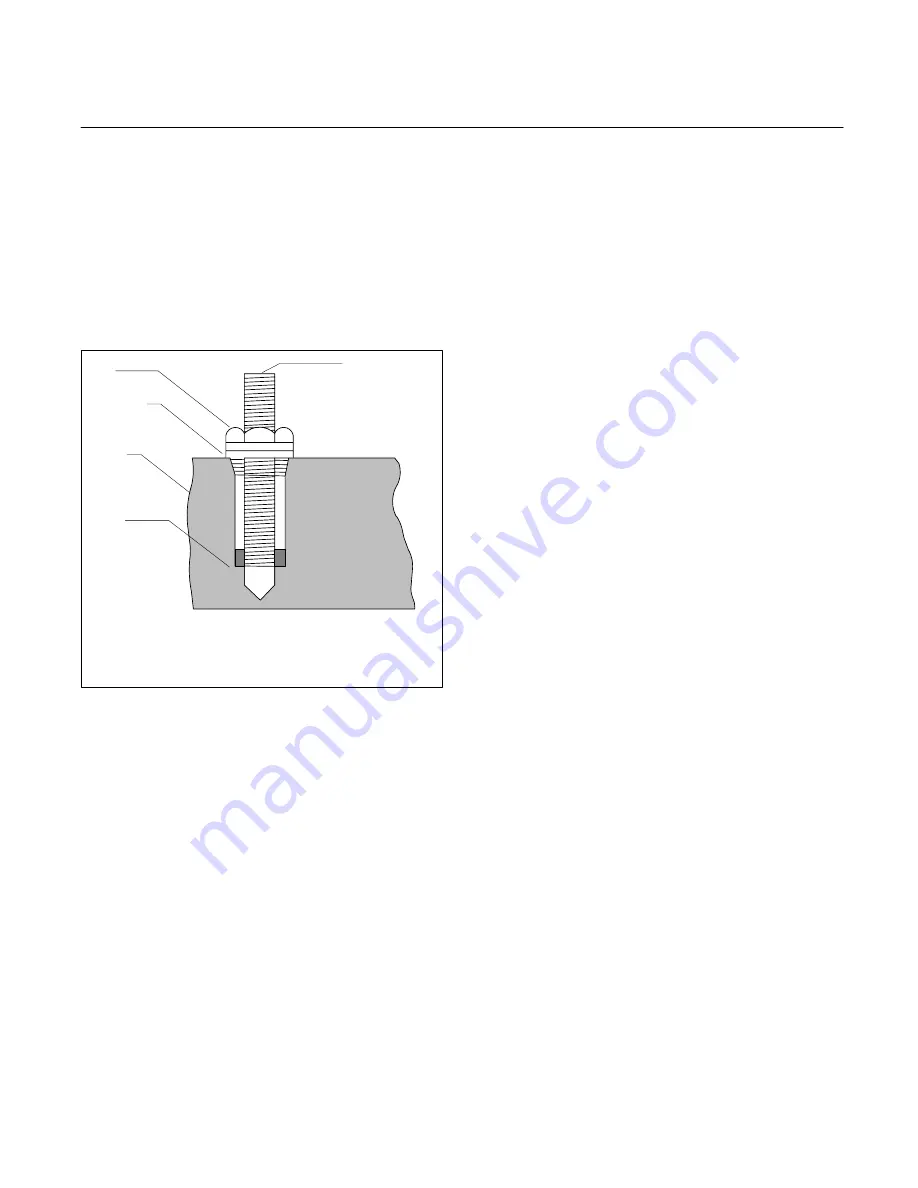

4. Inspect check valve (26) for excessive wear, erosion

and burrs. The seat contact area of the valve should have a

bright circular contact area. Leakage paths across the check

valve will show up as a break in the bright circular area. Ero-

sion of the seat area may also cause a leakage path to de-

velop. If seat (27) requires removal, tap seat with an ap-

propriate thread, then install a length of threaded drill rod into

the seat. Remove seat from the valve body. See Figure 4.

Vise grip

pliers here

Nut

Washers

Valve

body

Seat

Thread seat with a suitable tap, then install a length of

threaded drill rod into seat. Install washers and nut, then

hold th the top of drill rod with vise grip pliers. Pull seat

from the valve by turning nut clockwise.

Figure 4. Removal of seat

5. Inspect springs (19) and (25) for excessive wear and

damaged coils. Replace springs if coils are damaged. In-

spect springs for distortion. The ends of each spring must be

parallel to each other. Replace springs if distorted.

6. Inspect body (30) for burrs, nicks, plugged passages

and porosity. If either the metering spool, hydrostat or check

valve are to be replaced, throughly inspect the bore from

which the part was removed for defects. If the metering

spool requires replacement, and the unit is a FCGT-02-A-11,

remove and replace sleeve (15) before installation of the

new spool. Clean up sleeve with an India stone before the

spool is installed to remove the possibility of the existance of

burrs. Burrs can prevent the sleeve from entering the body

and/or the metering spool from moving free within the

sleeve. A very close slip fit exists between the body and

sleeve. (0.0009 – 0.0012 inch). DO NOT force at assembly.

If a problem exists, cool the sleeve before installation into

the body. This reduces the diameter of the sleeve and will

facilitate installation.

7. Inspect electrical connector (4) for solder splashes

between pins, cross threads and broken pins. Replace if

defective.

F. Assembly

Replace the gaskets and “O” rings removed from the unit

with those supplied in the seal kit. Lubricate “O” rings and

parts using clean system fluid to facilitate assembly.

Assemble parts in the reverse numerical sequence. Special

procedures are included in the following steps: (See Figure

3).

1. If nameplate (32) was removed, install a new name-

plate with four screws (31).

2. Install parts (29) through (24) into body (30). If seat

(27) or check valve (26) were defective, replace the check

valve and seat as follows:

a. Press a new seat into the body (chamfer end of

O.D. inward). Press seat in until it bottoms against the

shoulder. Clean bore before installation of check valve to

remove debris left from the seat installation.

b. Install a new check valve (26). The new check

valve must be seated (matched to the seat) to prevent

leakage. To seat a valve, first install valve into body without

the spring. Insert a brass rod (smaller than the spring)

behind the valve. Give the rod a sharp tap with a small

hammer. This will seat the valve within the body. Remove

the brass rod and valve. You will notice a circular pattern at

the seat contact area of the valve. This pattern must not be

broken or the valve will leak when put into service. Repeat

the seating operation if required. lubricate and assemble

valve (26), then install spring (25) and plug together. Torque

plug to 75–85 lb. in.

NOTE

In the following step, hydrostat (20) must be

installed with notch in small end parallel to

mounting face of valve and pointing toward the

electrical connector side of the valve body.

3. Install parts (23) through (16). Be careful not to cut

“O” rings during installation. Press plug (17) fully in with a

large “C” clamp. This will facilitate assembly of retaining ring

(16).

4. Position body (30) with mounting face down on the

workbench. Lay gasket (13) and spacer (11) in position on

the body. Lubricate and install metering spool (12) into

body(30).

5. Position torque motor (10) against body (30), (wires

to be located in wiring hole of body). Thread four screws (8)

with lockwashers (9) through torque motor, spacer and gas-

ket into body. DO NOT secure screws at this time.

6. Position torque motor armature above the metering

spool adjustment screw. With a 0.05 inch hex head tool,

thread the adjustment screw into the torque motor armature

nut. (Alignment of the metering spool will be required along

with the alignment of the torque motor during test.)

Pull the symbolized wires through the electrical connector

opening as far as possible. If the torque motor was replaced,

check the symbolization on the old motor to determine cor-

rect electrical connections. Refer to Table 4 and Figure 5 if

no connection information is available. Figure 5 will also help

you determine the correct wiring for the different types of

control systems used with torque motors. Table 5 defines the

input current required for a maximum armature deflection of

0.020 inch.