3

15kV Class Padmount VisoVac™

instruction manual

MN024004EN April 2021

Features and Construction

The VisoVac fault interrupter utilizes a stored-energy spring

charged mechanism for OPEN and CLOSE operations. The

gear comes standard with a spring charging motor on all

VFI (Vacuum Fault Interruption)-ways with optional spring

charge motors for all switched-ways. Each way comes with

OPEN and CLOSE pushbutton controls and spring charge

indication.

Terminations

Standard padmount terminations are IEEE 386 600 A

deadbreak elbow style bushings mounted in the rear of

the padmount enclosure on the opposite side of breaker

controls. This is also known as Eaton’s Control front/Cable

rear design (see

Figure 4

). Eaton also offers designs with

the bushings and breaker controls on the same side (see

Figure 5

). This style switchgear can be provided in double-

sided or single-sided layout designs.

The following figures show the features of each of these

designs.

Controls

Bushings

Figure 4 . Control front/Cable rear design . Controls are

located in front and switchgear bushings are located in

the rear of the enclosure .

Controls

Bushings

Figure 5 . Controls and bushings located on same side .

Applies to both double-sided and single-sided designs .

In some cases, 600 A to 200 A reducers are provided if load

break elbows are required.

Mounting

The switchgear can be mounted directly on the floor or

concrete pad. The switchgear is suited for indoor or outdoor

applications. Users should reference the mechanical

drawings provided with the switchgear for location of the

base mounting points associated with that equipment. The

following are common examples of location and spacing for

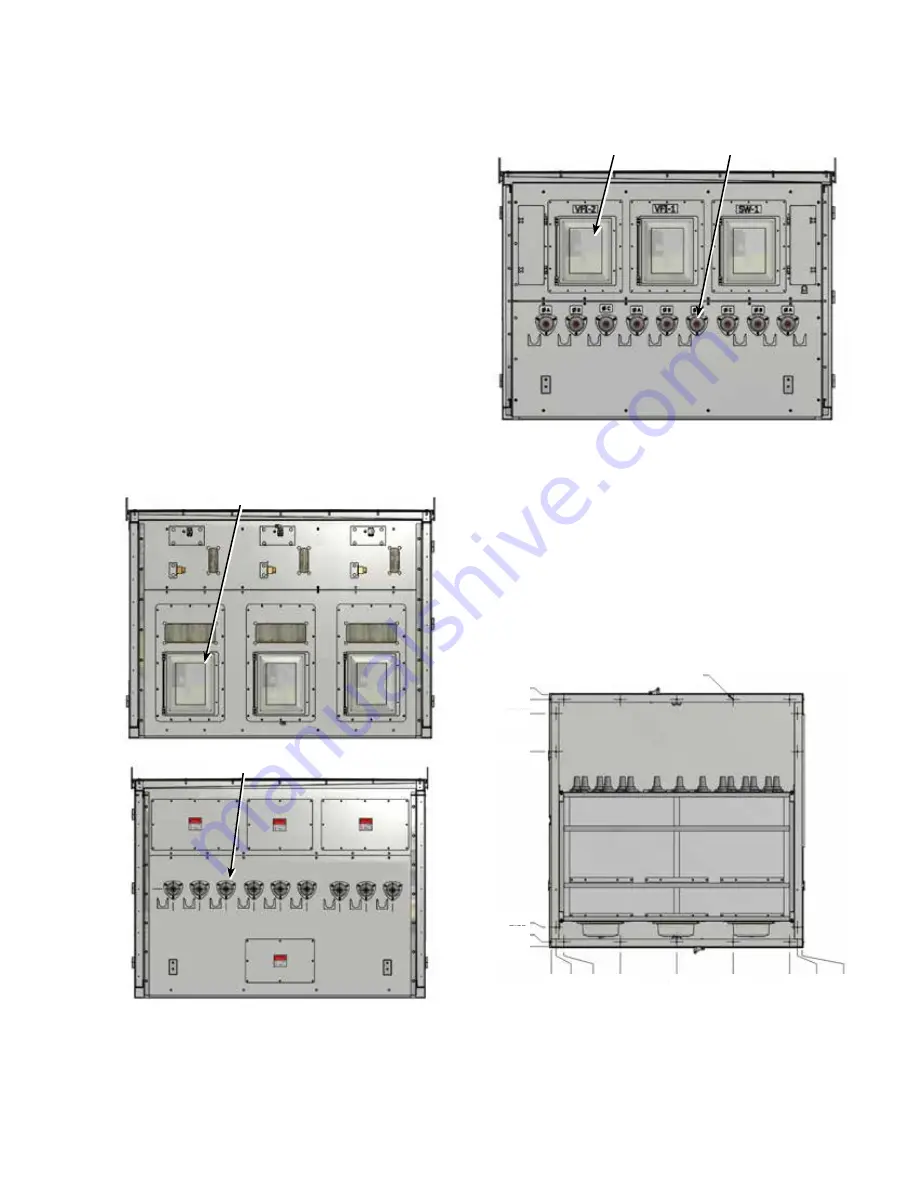

the base mounting.

Base mounting Ø.56 (16 Total)

80.00

79.50

73.99

61.99

5.99

1.50

.00

.0

0

1.

50

4.0

0

22.0

0

40.0

0

58.0

0

76.0

0

78

.5

0

80.0

0

Figure 6 . Control front/Cable rear base mounting

(dimensions in inches)