1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Technical Data

TD534-0501002U

Instructions for the Installation,

Operation and Maintenance

of W-SLC-7.2

Effective January 2013

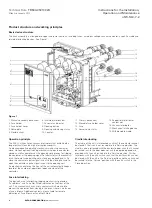

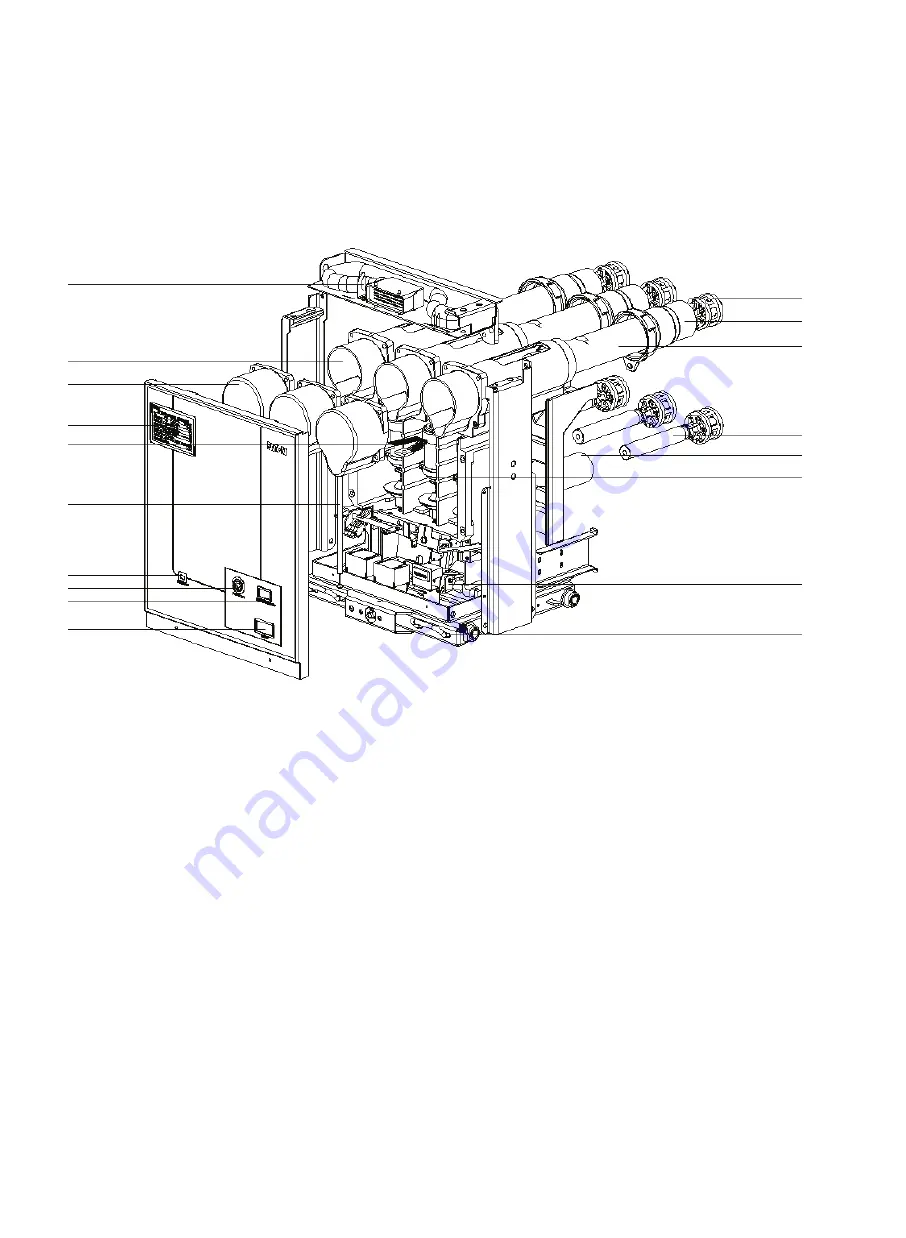

Product structure and working principles

Basic device structure

The truck assembly is arranged into upper and lower sections, including fuses, a medium voltage vacuum contactor, a specific cradle and

related interlocking devices. See Figure 1.

1. Manual secondary disconnect

2. Fuse holder

3. Fuse holder cover

4. Nameplate

5. Flexible shunt

6. Insulated interlock bar

7. Fuse status indicator

8. Opening button

9. Opening and closing status

10. Counter

11. Primary disconnect

12. Movable fuse holder cover

13. Fuse

14. Lower contact arm

15. Support plate for lower

contact arm

16. Vacuum interrupter

17. Mechanical latching device

18. Withdrawable cradle

Figure 1

Operation principle

The W-SLC utilizes Eaton vacuum interrupters that exhibit both a

long electrical life and a high interruption capability.

An electromagnetic operating mechanism makes the contactor

close, while an optional latching mechanism keeps the contactor

closed as well as compresses the opening spring ready for tripping

the contactor at the opening signal. For contactors with mechanical

latch, there are two operating coils, closing and opening coils. To

close the contactor a pulse signal is sent to the closing coil and to

open the contactor a pulse signal is sent to the opening coil.

An electronic counter on the front of the unit automatically keeps a

record of the number of operations (open and close) of the

contactor.

Cradle interlocking

The cradle of the unit is interlocked such that the contactor cannot

be closed if the truck is not racked into the ‘Service’ position. The

cradle is also interlocked with the enclosure door such that it cannot

be racked in with the door open nor can the door be opened are

provided with the unit racked into the ‘Service’ position. Further

interlocks with the earth switch such that the earth switch cannot

be closed with the unit in the ‘Service’ position and the unit cannot

be racked into the ‘Service’ position with the earth switch in the

Closed position.

Fuse interlocking

The device has an interlocking tripping mechanism to provide

‘Fuse Blown’ and ‘Fuse Not Fitted’ indication on the front of the

unit. This mechanism has auxiliary contacts which are used to

prevent the contactor from closing in the event there is no fuse or

a fuse is blown. Additional contacts are available for remote

indication of Fuse Blown or Fuse Not Fitted.

3

EATON CORPORATION

www.eaton.com