Technical Data

TD534-0501002U

Instructions for the Installation,

Operation and Maintenance

of W-SLC-7.2

Effective January 2013

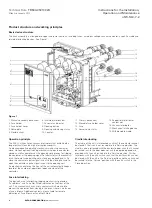

Commissioning and operating

The W-SLC has completed full factory tests and inspection before

being packed. Packing materials provide maximum protection and

convenient handling to the equipment during shipment .

BEFORE THE W-SLC IS PUT INTO USE, PLEASE FOLLOW THE MOUNTING

PROCEDURES STRICTLY. OTHERWISE, SHIPPING DAMAGE CAUSED

DURING TRANSPORTATION WILL NOT BE DETECTED AND THUS COULD

RESULT IN A MALFUNCTION OF THE UNIT IN THE FUTURE, WHICH MAY

CAUSE PERSONAL INJURY OR EQUPIMENT DAMAGE.

3. Storage

If the W-SLC is required to be stored before being put into use, it

should be stored in its original packing materials for maximum

protection. Before storage, examine the unit for any shipping damage,

Store the unit ONLY indoors in a clean, dry, well ventilated area to

avoid moisture condensation. If the indoor storage facility is not dry,

heaters should be provided to avoid condensation.

1. Initial check and operation

Before mounting the W-SLC, please carefully examine the unit for

any loose or damaged parts. Please check whether the unit’s

nameplate is in accordance with switchgear. If not, contact Eaton

immediately. Upon completion, insert the unit into the switchgear

and follow procedures 4.2.3 below.

2. Inspection of fuses

For most applications, fuses have already been installed before the

W-SLC is ready for shipment. Inspection is needed to see whether

fuses are damaged during transportation. For replacement and

mounting of fuses, please refer to relevant rules in Clause 5.6.

3. Pre-engineering operations

Before the W-SLC is moved into the switchgear, check whether

there are items within the panel which will prevent proper

operation.

The W-SLC has been inspected before delivery. Below preparations

shall be conducted before primary circuits are energized:

1) Before cradle operation, check whether cradle interlocks are

working. Do not use undue force, to avoid any damage to the

interlock mechanism:

a. Interlock mechanism is used to prevent from turning the

W-SLC cradle racking handle when the contactor closed;

b. Interlock mechanism is used to prevent contactor from

closing before the cradle is racked into the ‘Service’ position

or testing position

c. Interlock mechanism is used to prevent the racking handle

operating with the door open.

d. Interlock mechanism is used to prevent the compartment

door opening with the unit in the ‘Service’ position.

2) Connect the secondary connector and apply secondary power

and operate the contactor according to procedures. Then check

whether opening and closing position indicator is working

properly

3) Move the cradle from ‘Test’ position to ‘Service’ position,

according to below procedures:

Close the compartment door and ensure all bolts are tightened.

Ensure that the Earth Switch is ‘Open’. Insert the cradle racking

handle into the cradle socket. Turning in a clockwise direction to

rack in (into ‘Service’ position) while turning in a

counterclockwise direction to rack out (into ‘Test’ position). The

total cradle racking travel from testing position to service

position is about 200mm. If all the interlock conditions to prevent

the cradle from moving have been met, turn the handle 20 cycles

in a moderate speed. When it clicks (the sound when position

switch inside the cradle operates), it means it’s in the correct

position. Do not use excessive force as this may to damage on

the operating mechanism. At this moment, the corresponding

position indicator (S8, S9) circuits are closed to indicate correct

position of the unit within the switchgear.

WARNING

NOTICE

ENSURE THAT FUSES ARE MOUNTED IN A CORRECT ORIENTATION.

7

EATON CORPORATION

www.eaton.com

Mounting, commissioning and operating

Receiving, handling and storage

The W-SLC has completed full factory tests and inspection before

being packed. Packing materials provide maximum protection and

convenient handling to the equipment during shipment .

1. Receiving

Maintenance and testing of the W-SLC shall only be carried out

when the unit is removed from the panel and placed on a stable

workbench.

Examine the W-SLC for any signs of shipping damage such as

broken, missing or loose fastenings, damaged insulators or other

deformed parts. If damage or loss is detected, please claim

immediately with the carrier and notify Eaton.

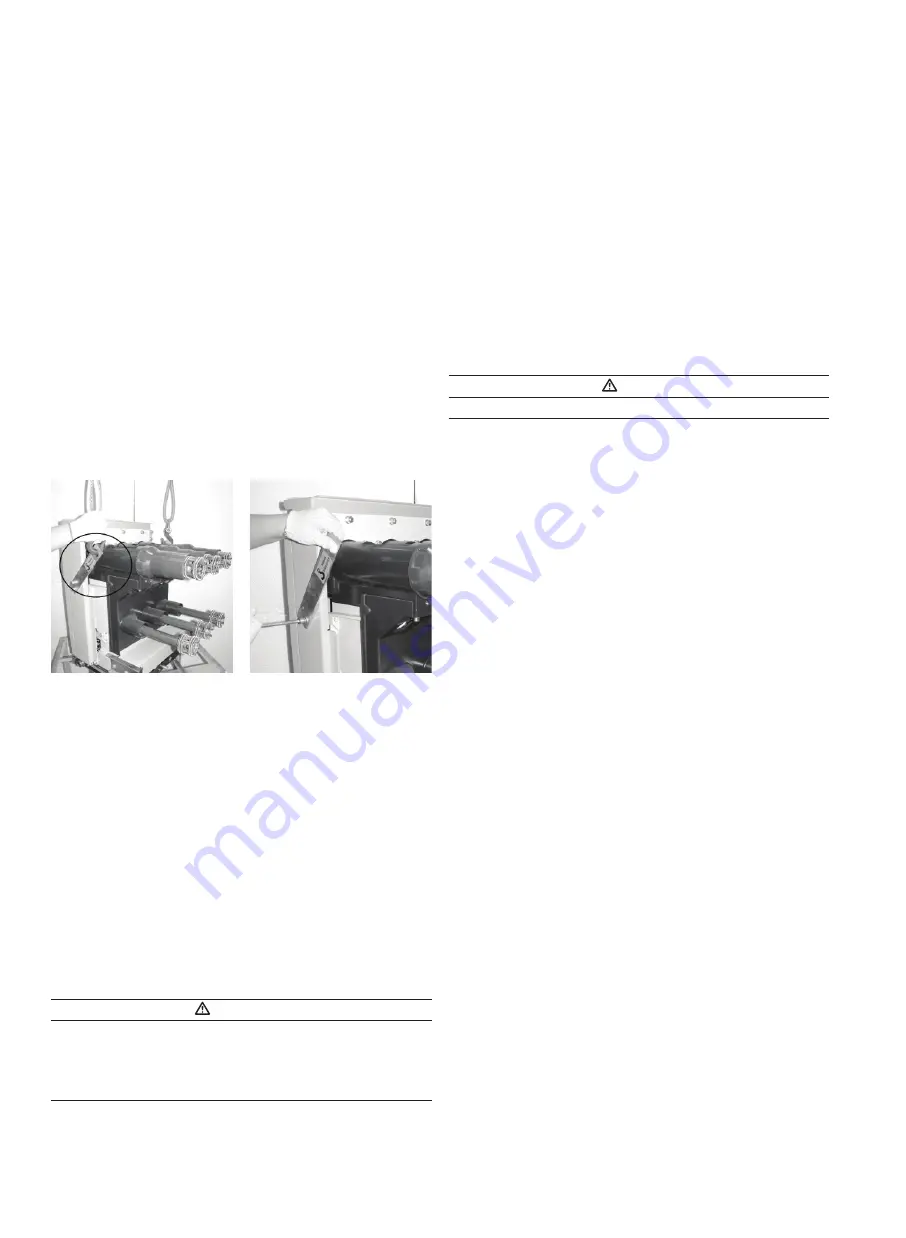

2. Handling

The W-SLC is equipped with special lifting lugs for lifting and

transport. Please refer to Figure 5.

Figure 5

Figure 6

After transport, the lifting lugs on both sides need to be removed

before the unit is ready to be inserted into the switchgear. Please

see Figure 6. For detailed procedure for racking into the

switchgear please refer to the switchgear manual.