EAU FLOW 505

FOR HELP & ADVICE, PLEASE EMAIL

technical@cleancert.co.uk

OR CALL

08443 511115

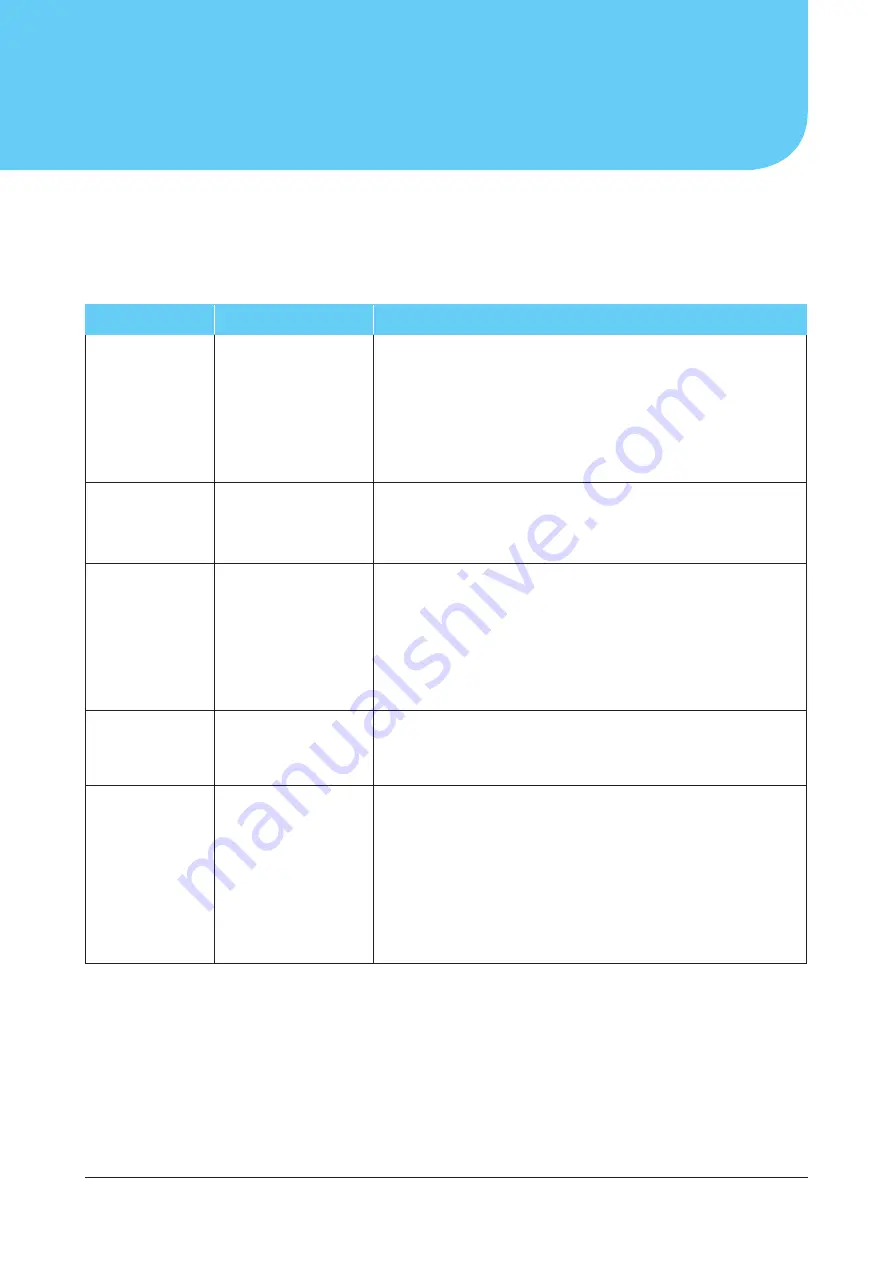

ISSUE

REASON

RESOLUTION

999 appears in

display screen

cartridges warning lights

have been left flashing

To remove it:

a) Press ‘Set’ button for 3 seconds

b) Then Press ‘Zero’ button for 3 seconds

c) Then unplug the RO unit within 1 second

d) Then turn on again within 10 seconds.

The ‘999’ should disappear.

RO Machine

bleeping and

number light

flashing

Cartridge needs

changing

a) Turn off water coming into RO and change all 5 cartridges.

b) Now press zero button for 5 seconds until it bleeps

‘!’ light flashing

TDS level in water too

high

a) If it has been over 9-12 months since last changing cartridges/installed

machine then change all 5 cartridges

or

b) If it has been less than 9 months since you changed cartridges, then

you need an additional blue Di cartridge EY30810 (plus inline TDS meter

EY20155) between RO and dispensing valve/tap. Contact your rep for

details.

‘Power’ light

flashing

Electricity fault

a) Change fuse in plug

Or

b) You need a new PCB board

5 lights flashing

red- leak detector

alarm

Water detected in base

of unit, normally caused

by not turning off

water before changing

cartridges

a) Ensure cartridges are fully secured and not leaking

b) Remove panels (slide back black panel, undo white clips and lift up

white panel).

c) Mop up water in base of unit and ensure it is fully dry.

d) You might also need to turn RO unit on its side to get rid of any excess

water in the base. Have a cloth underneath for this purpose.

e) Pull up TDS probe on front LHS (black wire connected to base), wipe

with a cloth and replace. Ensure chamber is fully dry before replacing.

Common Troubleshooting Issues

Issues, reasons and resolutions