EBA 430 E • EBA 430 EP

-29-

1.

2.

1.

3.

2.

-28-

B

A

The 3 eccentrics are now exposed and should

be turned counter clockwise to position "0"

with the special wrench (A) (found in tool set).

Until the red arrow-like eccentric marking

corresponds to the position "0" (B).

Remove the special wrench and turn on the

main switch until the blade returns to the home

position.

Danger! Do not put main switch on position

"0" whilst blade is moving upwards! The clamp

must always overlap the blade! Risk of injury!

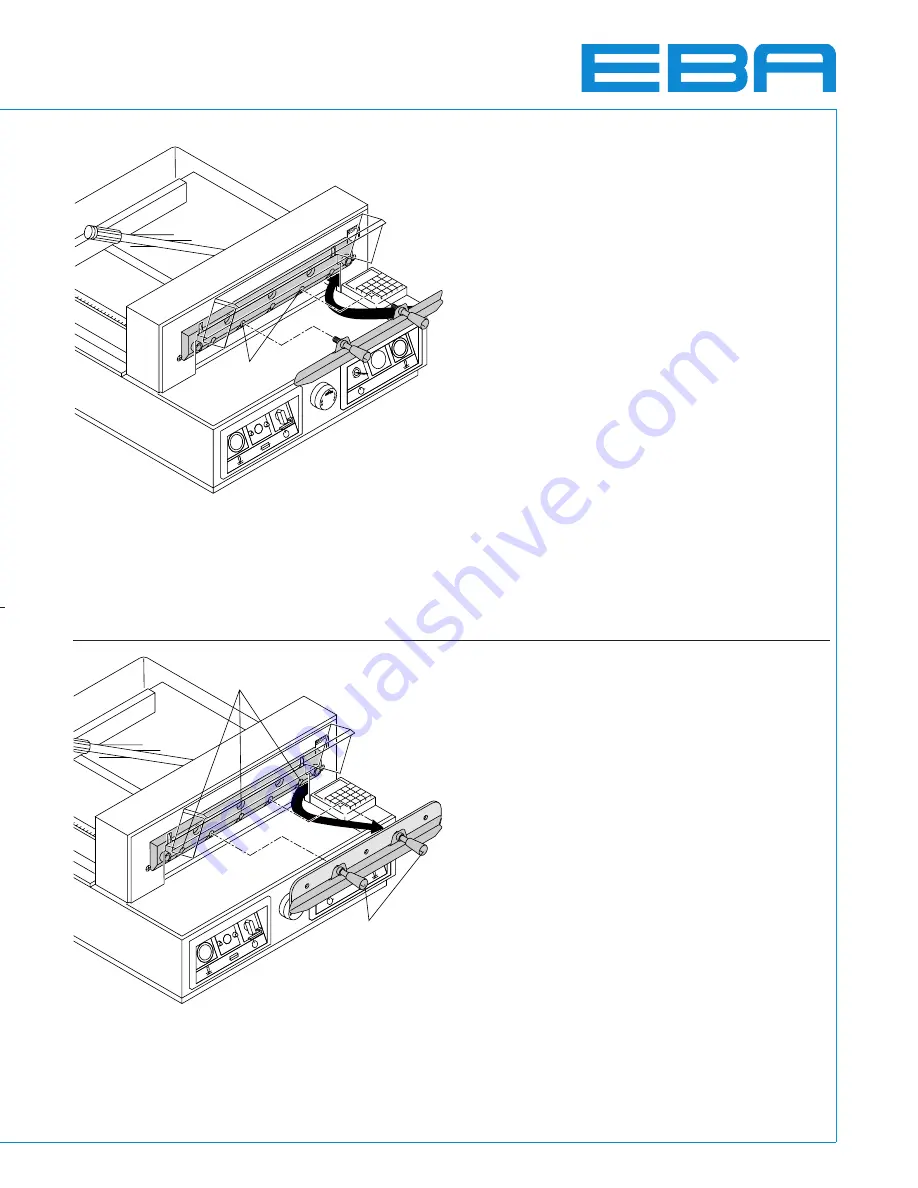

Remove the 2 blade screws (1.). Then put the

blade changing tool (2.) into place and fasten it

to the blade.

The remaining screws should then be removed

(1.). Loosening the grips of the blade changing

tool lightly (2.) will now allow the blade to be

taken downwards out of the machine (3.).

Clamping

Blade

OK

OK

Summary of Contents for 430 E

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...11 When not in use for a longer period switch off Main switch to 0...

Page 12: ......

Page 14: ......

Page 16: ......

Page 18: ......

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 28: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 38: ......

Page 40: ......

Page 42: ......

Page 44: ......

Page 46: ......