CD425 OWNERS MANUAL

Drawing No. :- TPC252

Issue :-

1

Date :-

13/10/03

CD425

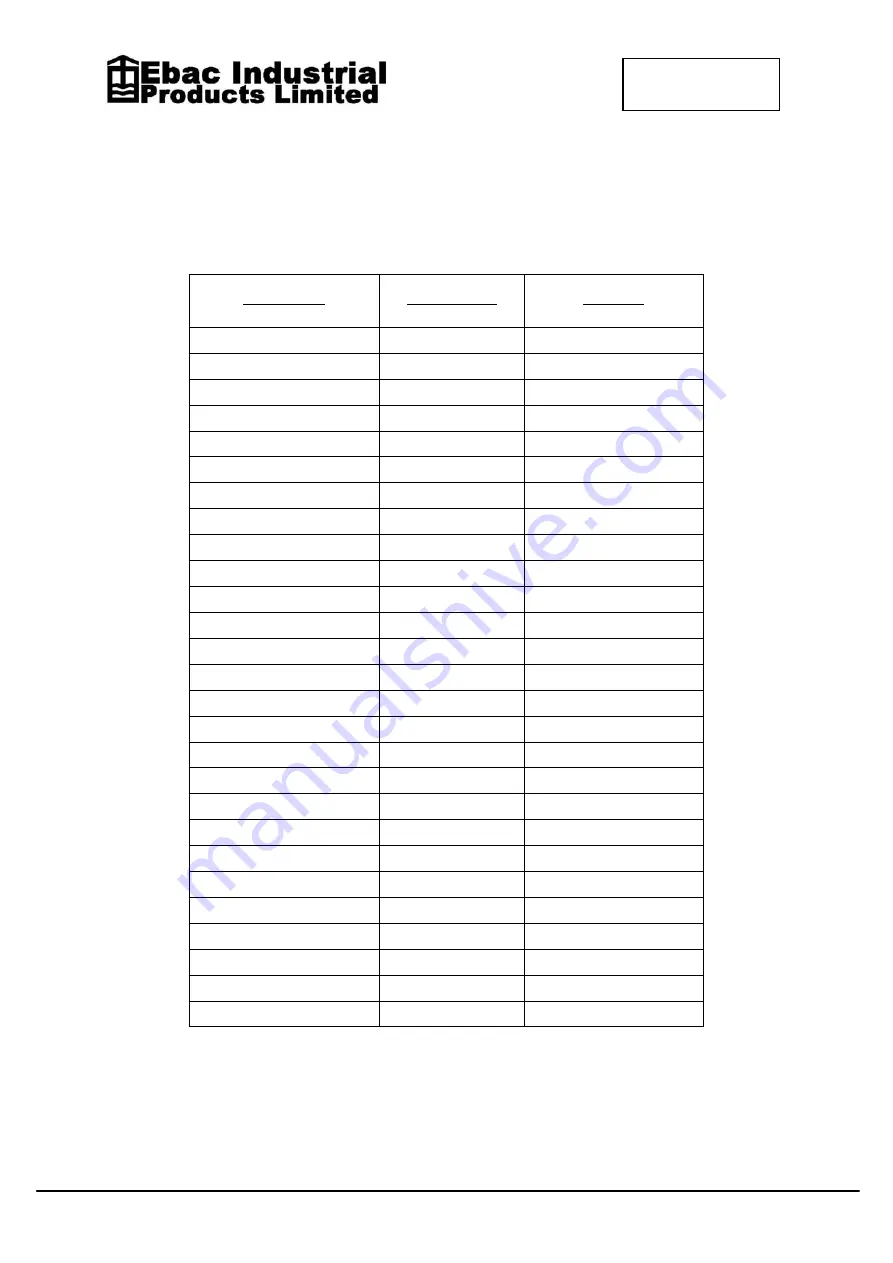

SPARE PARTS LIST

D

ESCRIPTION

P

ART

N

UMBER

Q

UANTITY

Compressor 3022176

1

Condenser Coil

3020725

1

Evaporator Coil

3020733

3

Defrost valve

3020803

1

Reversible Filter Dryer

3020930

1

Capillary Tube

3014251 12

X

1400mm X 0.047

R22 Freon Refrigerant

3100451

2.5kg

Drain Tube

2014315

3 meters

3/8” Copper Tube

3014203

2 meters

1/2” Copper Tube

3014204

2 meters

5/8” Copper Tube

3014205

2 meters

Cork Tape

3100223

1/2 Roll

Fan Motor

3030140

1

Axial Fan

3010119

1

Solenoid Coil

3030402

1

Humidistat 1132200

1

Momentary Switch

3030634

1

Indicator Lamp Holder

3034513

2

12V 100ma Lamp

3034522

4

Humidistat Control Knob

2017707

1

Contactor 037H0021

3030355

1

Contactor 037H0041

3030362

1

Relay 3030270

1

Overload 3032646

1

Transformer 3031129

1

Delay Timer

1602400

1

Defrost Timer

1601200

1