(38)

8 Troubleshooting

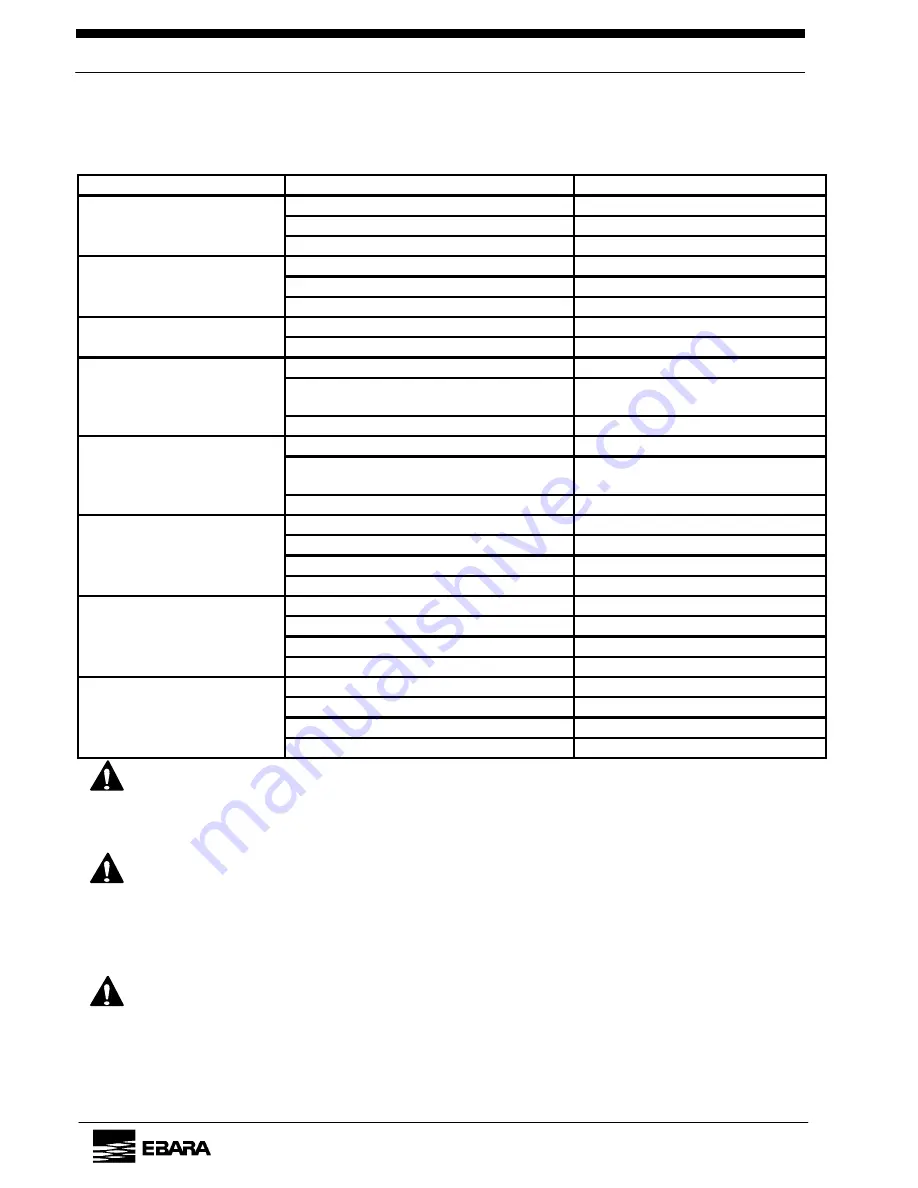

8.1 Troubleshooting (1) Basic Trouble

Abnormal symptom

Check Item Corrective

Action

Incorrect wiring

Check wiring

Ground fault

Replace or overhaul pump

Circuit breaker is activated.

(Leakage detector is on.)

Short circuit

Replace or overhaul pump

No power supply to pump

Check power supply

Connector is not connected

Connect power connector

Power LED does not come

on.

ELB is not mode ON

Switch ELB ON

ELB is not mode ON

Switch ELB ON

Nothing appears on LCD.

Display is abnormal.

Instruments are in failure

Replace instruments

Mode is set in “Remote”

Set switch to “Local” mode

Start-up conditions are not satisfied

(“STARTFAIL” is displayed)

Satisfy all start-up conditions

MP does not start when

pressing START button.

Instruments are in failure

Replace instruments

Mode is set in “Local”

Set switch to “Remote” mode

Mode is set in “Alternate”

(Pump jogs)

Apply “Alternate” start signal

Set to “Momentary” mode

MP does not start when

applying START signal.

Instruments are in failure

Replace instruments

Leakage on vacuum piping

Check piping

MP insufficient vacuum

Replace or overhaul

BP start signal is not applied

Apply BP start signal

BP does not start.

Instrument failure

Replace instruments

Adjuster foot is not lowered

Properly set all adjuster feet

Cover is in contact with other items

Remove objects from cover

Cover screws loose

Tighten mounting screws

Abnormal noise.

Excessive vibration.

Pump part is damaged

Replace or overhaul pump

Byproducts settled in piping

Clean up piping

N

2

pressure setting is high

Set pressure for correct value

Leakage from vacuum piping

Check piping

Vacuum pressure increase.

Byproducts settled in pump

Replace or overhaul pump

WARNING

Interrupt Earth Leakage Breaker (ELB) or CB and lock out power

before starting on wiring and maintenance work.

Do not switch on the power supply to the pump until work is

completed.

WARNING

The pump casing and exhaust piping become extremely hot during

operation and for some time after stopping.

Keep pump and exhaust piping away from contact with personnel and

flammable substances.

Do not remove the pump cover during operation.

WARNING

Check for gas leaks after installing and maintaining the piping.

Gas leaks will result in the discharge of harmful and dangerous

substances and in abnormal reactions due to the admission of air into

the pump

EBARA

Corporation

Summary of Contents for A70W

Page 9: ...vii EBARA Corporation...

Page 10: ...viii EBARA Corporation...

Page 11: ...ix EBARA Corporation...

Page 14: ...xii Blank page EBARA Corporation...

Page 21: ...7 EBARA Corporation Outline Drawing A70W...

Page 22: ...8 Outline Drawing A30W EBARA Corporation...

Page 23: ...9 EBARA Corporation Outline Drawing A25S...

Page 24: ...10 EBARA Corporation Outline Drawing A10S...

Page 25: ...11 EBARA Corporation Outline Drawing A07V...

Page 60: ...46 Blank Page EBARA Corporation...

Page 63: ...III Label Country US Label Emergency Number 716 293 3330 EBARA Corporation...