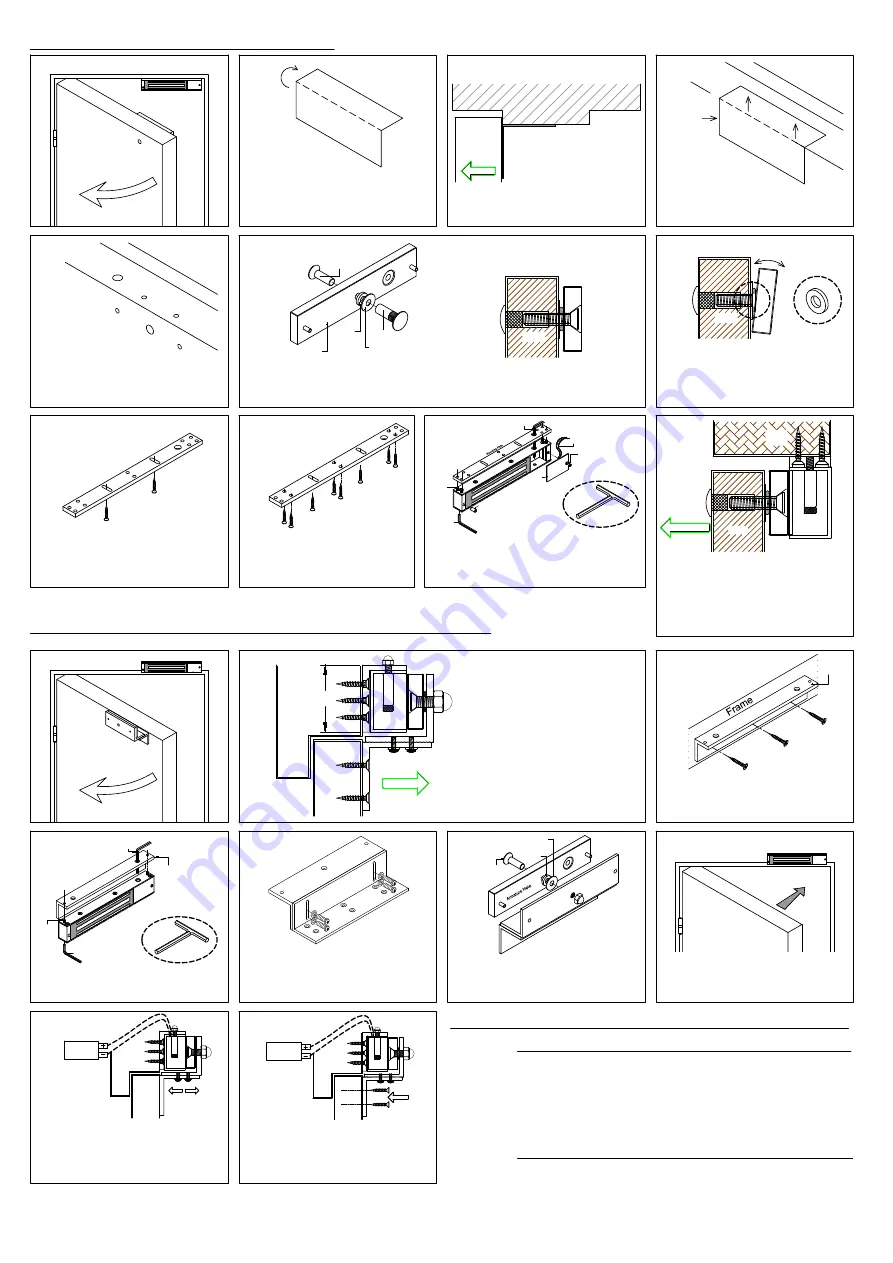

Out Swing Door

1

Installation

Template

Fold the Installation Template

Door

Door Frame

Template

Out Swing

2

Close the door & position the

template at the lock jamb side of

the frame with a gap 10mm.

3

Door Frame

Mark & drill holes according to

template indications.

Door

4

Drill 3 holes on door frame and

3 holes on door as indicated on

the installation template.

5

Install the Armature Plate to the door.

Note: Do not over tighten the armature screw which would affect the

armature plate flexibility to pivot around the screw.

Door Frame

Door

Door

Armature Plate

Sexnut Bolt

Rubber

Washer

Metal

Washer

Armature

Screw

Wooden Door

Loosely tighten screw through the

adjustable slot on mounting plate

to the door frame as indicated on

installation template.

7

Make sure the mounting plate

& armature align properly,

then screw in the balance

mounting screws.

8

Use allen wrench to unscrew anti tamper

nut and install the lock by tighten the

fixing screws on the mounting plate. Pull

cable wire through frame to lock housing.

9

Holding Force

Door

Frame

Door

EM Lock

10

Connect to power supply and test

the unit functionality.

Basic Bracket Installation Guide

Door

Rubber Washer

This allow the armature plate to

pivot around the armature screw

to compensate the door

misalignment.

6

ZL Bracket for In-Swing Door Installation Guide

In Swing Door

In-Swing

1

Door

Frame

Door

EM Lock

L

2

Position the L-Bracket mounting

location as close to the door upper

corner with gap min.10mm; make

sure the door is closable.

3

L-Bracket

Fixing Screw

x2

Allen Wrench

12/24 VDC

Power

Mounting

Bracket

Cable Wire

Tighten the EM Lock on the

L-Bracket by using Allen Wrench.

4

Assemble the Z-bracket and make

sure the Z bracket can be adjust

freely, before permanent tighten.

5

Install the armature plate on the

Z-Bracket; using the CSK screw

given in screw pack.

Rubber

Washer

Flat Washer

Armature

Screw

6

Close the door, and position the

Z-Bracket by bringing the armature

plate close to the EM Lock surface.

7

Turn On the power of EM Lock, let

the armature plate attach to EM

Lock; adjust the position between

the Z-Bracket and the door.

Power

Supply

Door

8

Once the position is correct, screw

in the self tapping screw on the

Z-Bracket to the door. This should

be the last step.

2-2

Distance in feet from power supply to the furthest lock unit

Minimum

Wire Gauge

(AWG) for

12VDC

Amps 25f 50f 75f 100f 150f 200f 250f 300f 400f 500f

0.25

18

0.50

0.75

1.00

1.50

2.00

18 18

18

18

16

16

14

14

12

18 18 18

16

16

14

12

18 18 16

14

12

12

18 16 14

14

12

18 14 12

12

16 14 12

1000f

Minimum

Wire Gauge

(AWG) for

24VDC

Amps 25f 50f 75f 100f 150f 200f 250f 300f 400f 500f

0.25

18

0.50

0.75

1.00

1.50

2.00

18 18

18

18

18

18

18

16

16

18 18 18

18

18

16

16

18 18 18

18

16

14

18 18 16

16

14

18 18 16

14

16 16 14

1000f

16

14

14

12

14

12

12

14

12

12

14

12

14

12

Note: Installation Template only applicable for

model lock 300, 600, 800, 1200.

** T Handle

Allen Key 3mm

Not Supply

** T Handle

Allen Key 3mm

Not Supply

Important notice: Proper alignment

between magnet & armature plate is

important for the lock operate

normally.

12/24 VDC

Power

Cable Wire

Fixing

Screw

PCB Cover

Cover

Screw

Allen

Wrench

Anti Tamper Nut

Mag. Ctc. Wire*

Power

Supply

Door

EISB-EMS-IG Ver.A Publish:11.3.2020

The door frame min. height

value "L" is needed to

accommodate the bracket

Model:

- 300ZL(L) = 39mm

- 600ZL(L) = 46mm

- 800ZL(L) = 52mm

- 1200ZL(L) = 73mm

- 1500ZL(L) = 76mm

Remark: All drawing shown are for illustration purpose only.

Actual product may vary due to product enhancement.