page 4 of 5

Check connections

NOTE

DC-fans <=60V are products of Protection Class lll and must be

operated with safety extra-low voltage.

Connect product

Check the product for visible damage and the operability of protective

equipment before switching on.

If damage is visible, do not start the product.

5

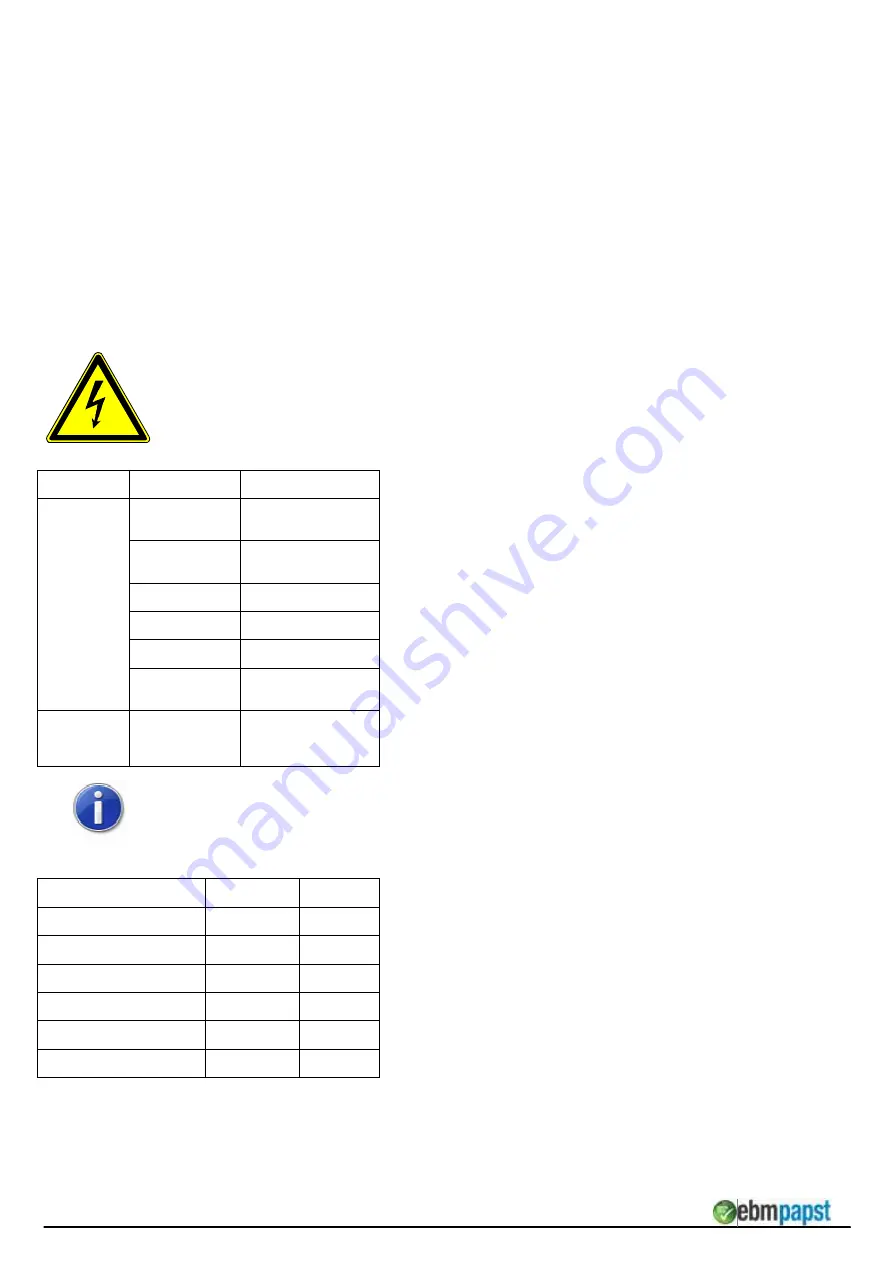

FAULTS, POSSIBLE CAUSES AND REMEDIES

Replace your product by a new one, do not repair it.

DANGER

Electrical voltage at motor

Wait five minutes after the voltage

(all poles) has been switched off

before opening the product.

Fault/

Error

Possible cause

Possible remedial

action

Mechanical

blocking

Switch off, de-energize

and eliminate

mechanical blocking.

Mains voltage fault Check mains voltage,

re-connect voltage

supply.

Connection faulty

Rectify connection, see

pin connection.

Motor is too hot

Allow motor to cool /

identify cause of fault.

Motor winding

interrupted

Exchange product.

Motor is not

rotating

Ambient

temperature too

high

Reduce ambient

temperature if possible.

Impeller out of

true

Unbalance of

rotating parts

Clean product if still

unbalanced after

cleaning, exchange

product.

In case of further faults, contact ebm-

papst.

Technical safety inspection

What requires checking?

How to

check?

Frequency

Protection against accidental

contact/ protective clothing

Visual

inspection

min. 1/2

yearly

Check product for damage

Visual

inspection

min. 1/2

yearly

Fixation of product

Visual

inspection

min. 1/2

yearly

Fixation of wires

Visual

inspection

min. 1/2

yearly

Insulation of wires

Visual

inspection

min. 1/2

yearly

Check impeller for

wear/sediments/ corrosion

Visual

inspection

min. 1/2

yearly

6

APPROVALS

The product bears the CE mark.

The CE mark is affixed to adequately sized nameplates.

Within the meaning of the EMC Guideline 2004/108/EU this document

is intended as:

-

Mounting instructions as per Art. 9, Paragraph (3)

-

Installation instructions as per Art. 3

-

Operating manual as per Art. 9, Paragraph (3)

-

Instructions for use as per Art. 8, Paragraph (2); Art. 9, Paragraph

(5)

-

Maintenance instructions as per Art.3; Art.9, Paragraph (3)

Usage restrictions for residential areas as per Art.9, Paragraph (4)

Accompanying documents as per Annex V, Cl. 3

Within the meaning of Directive 2006/95/EU - use of electrical

equipment within specific voltage limits - this document is intended

-

Instructions for use Art. 10, Paragraph 1

Within the meaning of the Directive 2006/42/EU Machine Guideline,

this document is intended as

-

Mounting instructions as per Art. 13, Paragraph 1b

The information in this document and in the specification applies to

mounting, installation, operation, use and maintenance.

Summary of Contents for 8414 NGM

Page 5: ...page 5 of 5 ...