Operating instructions

A2E250-AL86-74

Pfannenberg GmbH

Translation of the original operating instructions

3. TECHNICAL DATA

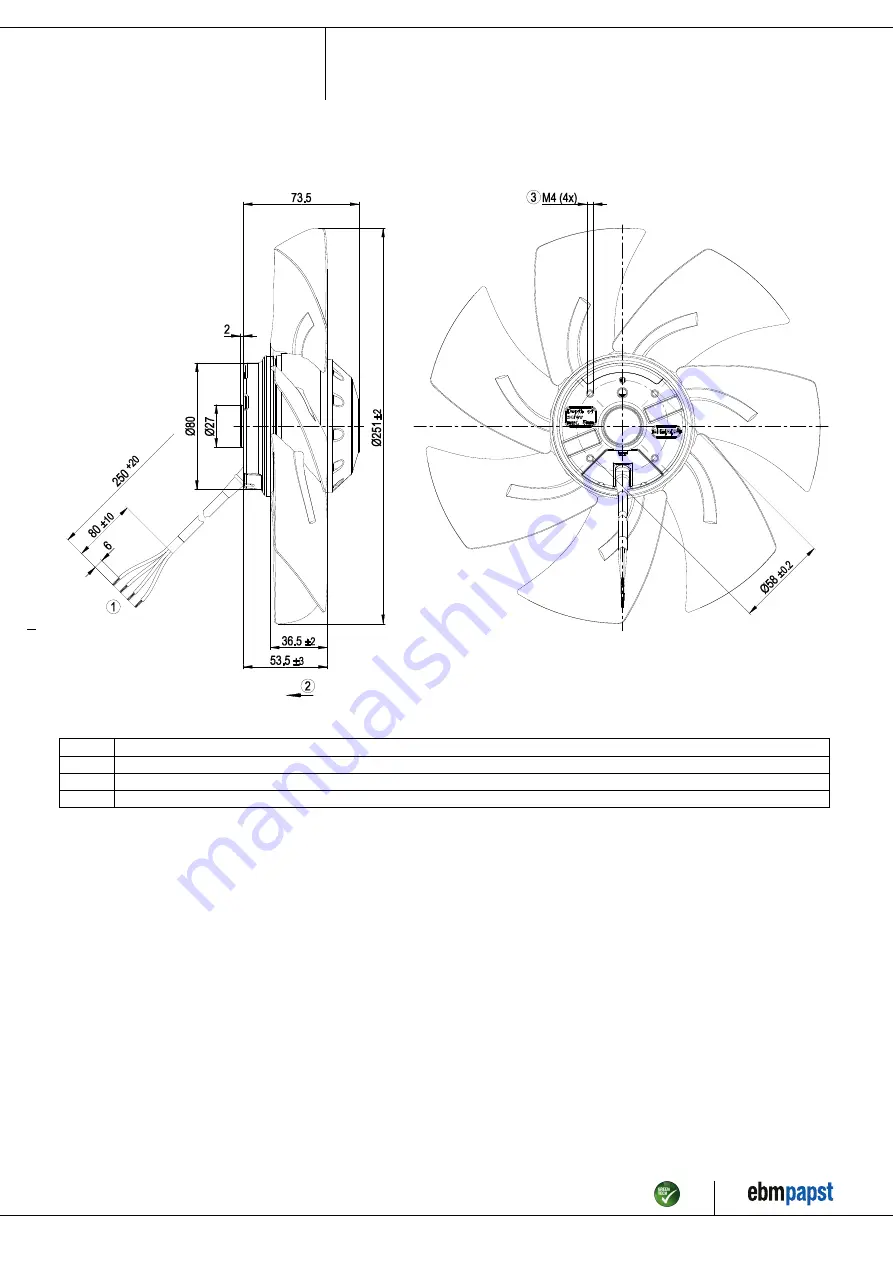

3.1 Product drawing

All dimensions in mm.

1

Cable PVC 4G 0.5 mm²

4x splice

2

Airflow direction "V"

3

Max. screw-in depth 5 mm

Item no. 11875-5-9970 · ENU · Change 226421 · Approved 2021-02-15 · Page 4 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com