Operating instructions

A3G500-AN33-03

Translation of the original operating instructions

Fig. 3: Fan installed lying flat, cable routed in a U-shaped loop.

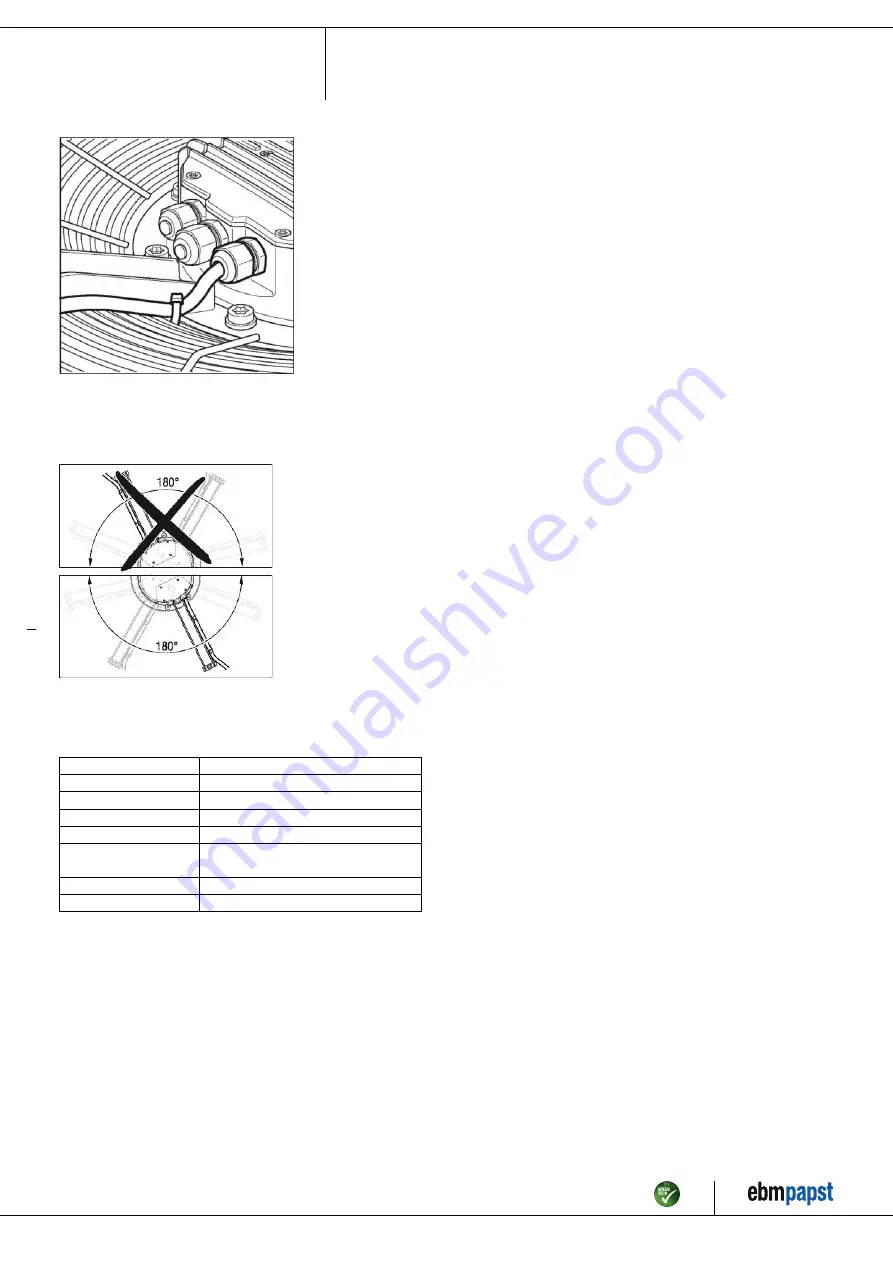

Fans installed upright

When routing the cable, make sure that the cable glands are located at

the bottom. The cables must always be routed downward.

Fig. 4: Cable routing for fans installed upright.

4.4 Factory settings

Factory settings made for the device by ebm-papst.

Mode

PWM control

Group address

1

Fan/device address

1

Max. PWM / %

100

Min. PWM / %

0

Save set value to

EEPROM

Yes

Set value requirement

Analog

Direction of action

Positive (heating)

Item no. 50313-5-9970 · ENU · Change 205336 · Approved 2020-10-01 · Page 9 / 13

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com