Operating instructions

A4E300-AU26-07

Translation of the original operating instructions

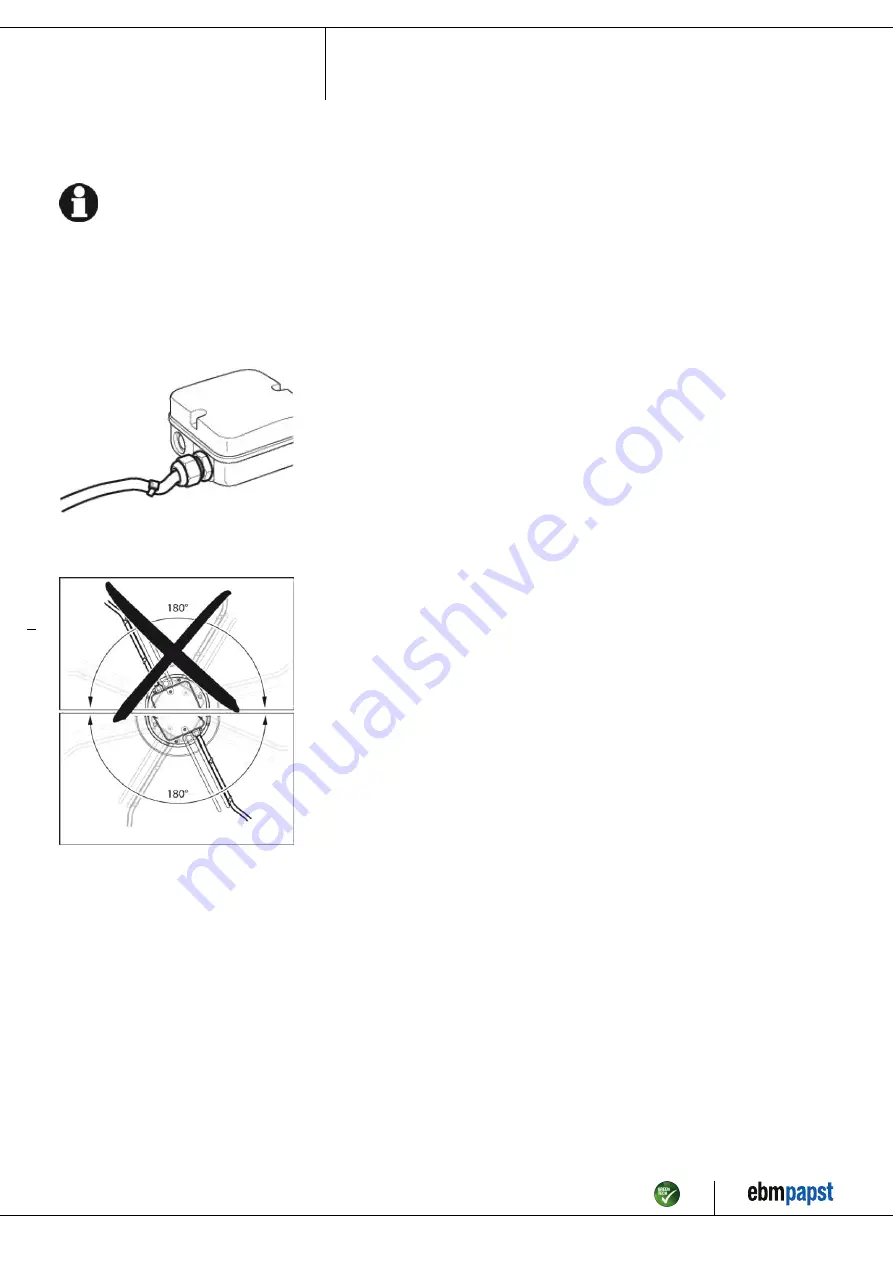

4.3.1 Cable routing

Water must be prevented from reaching the cable exit along the cable.

NOTE

Damage caused by moisture penetration.

Moisture can penetrate into the terminal box if water is

constantly present at the cable glands.

→ To prevent the constant accumulation of water at the cable

glands, the cable should be routed in a U-shaped loop

wherever possible.# If this is not possible, a drip edge can

be produced by fitting a cable tie directly in front of the cable

gland for example.

Fans installed lying flat

Fig. 1: Fan installed lying flat, cable routed in a U-shaped loop.

Fans installed upright

Fig. 2: Cable routing for fans installed upright. The cables must always

be routed downward.

Item no. 12073-5-9970 · ENU · Change 96832 · Approved 2018-01-18 · Page 7 / 10

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com