Part Number

Operating Instructions

Item no. LS-128.

Revision 002

Release 17/02/2016

Page 5 of 8

ebm-papst A&NZ Pty Ltd

10 Oxford Road · Laverton North VIC 3026 · Phone +61 (03) 9360 6400 · Fax +61 (03) 9360 6464

ABN 33 115 927 556

NSW Phone +61 (02) 9827 6400 · NSW Fax +61 (02) 9827 6464 · NZ Phone +64 (09) 525 0245 · NZ Fax +64 (09) 525 0246

sales@ebmpapst.com.au · www.ebmpapst.com.au

EBM ALPHA

3.2

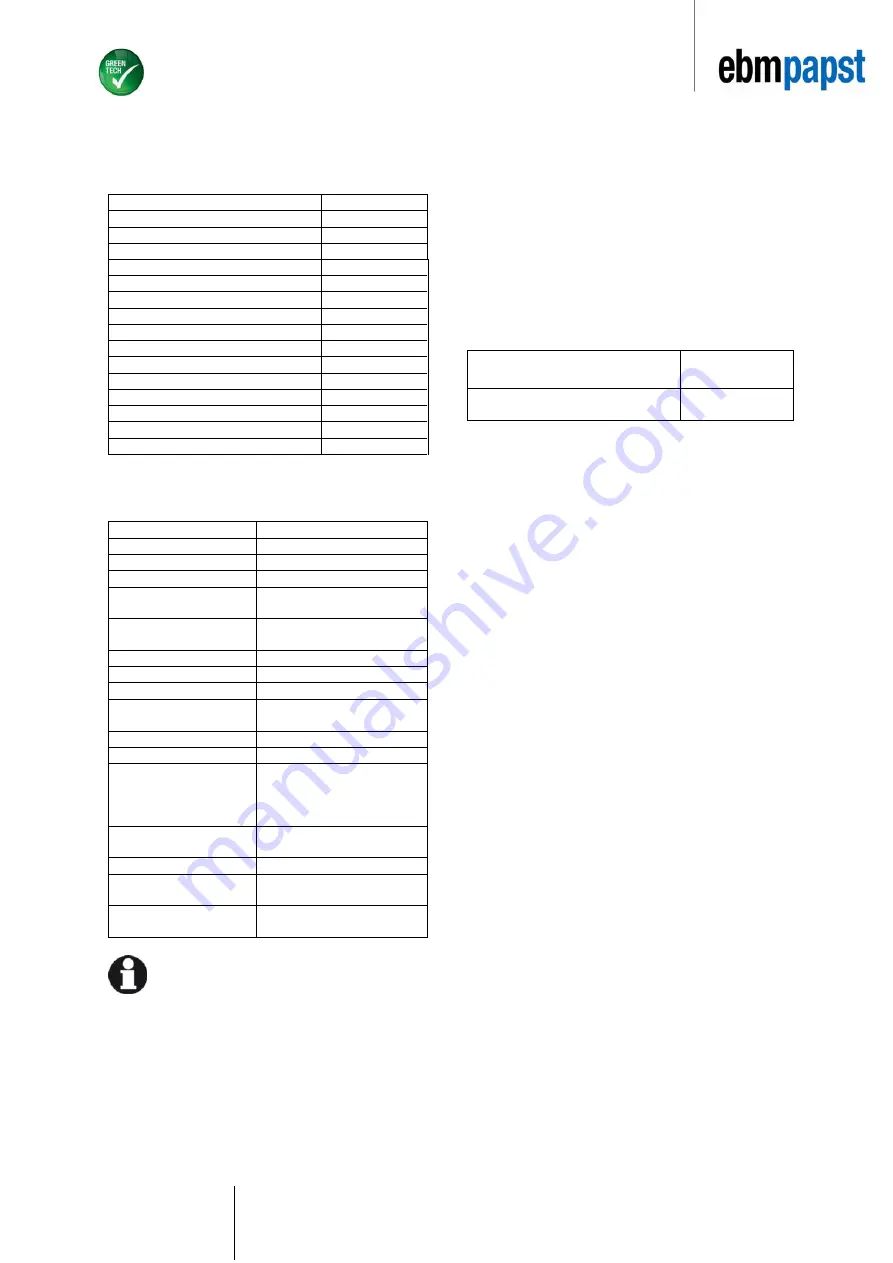

Nominal data

Motor

M2E068-BF

Phase

1~

Nominal Voltage / VAC

240

Frequency / Hz

50

Valid for approval / standard

CE

Speed / rpm

2700

Power input / W

50

Flow at 1m head / l/min

32

Flow l at 2m head / l/min

25

Min. water level / mm

57

Max. water level / mm

135

Current draw / A

0.17

Motor capacitor / µF

1

Capacitor voltage / VDB

450

Min. ambient temperature / °C

-25

Max. ambient temperature / °C

60

Subject to alteration

Typical data can vary by location and filter material

3.3

Technical features

Mass

1.38 kg

Surface of rotor

Coated in black

Housing material

Recycled ABS

Direction of rotation

Clockwise, seen on rotor

Motors type of

protection

IP 44; depending on

installation and position

Junction box type of

protection

Must be stored in a dry

environment

Insulation class

“B”

Humidity class

F1-2

Mounting position

Any

Condensate discharge

holes

None

Operation mode

S1

Mode bearing

Ball bearing

Touch current acc. IEC

60990 (measuring

network Fig. 4, TN

system)

< 0.75 mA

Motor protection

Thermal overload protector

(TOP) wired internally

Cable exit

Variable

Protection class

I (if protective earth is

connected by customer)

Product conforming to

standard

EN 60335-1; CE

For cyclic speed loads, note that the rotating parts of

the device are designed for maximum one million

load cycles. If you have specific questions, contact

ebm-papst A&NZ for support.

3.4

Mounting data

For depth of screw, see chapter 3.1 Product drawing

Secure the mounting screws against accidentally coming

loose (e.g. by using self-locking screws).

You can obtain additional mounting data from the product

drawing if necessary.

3.5

Transport and storage conditions

Use the device in accordance with its protection type.

Max. permissible ambient motor

temp. (transp./storage)

+ 80 °C

Min. permissible ambient motor

temp. (transp./storage)

- 40 °C