Operating instructions

D1G146-LV03-06

Translation of the original operating instructions

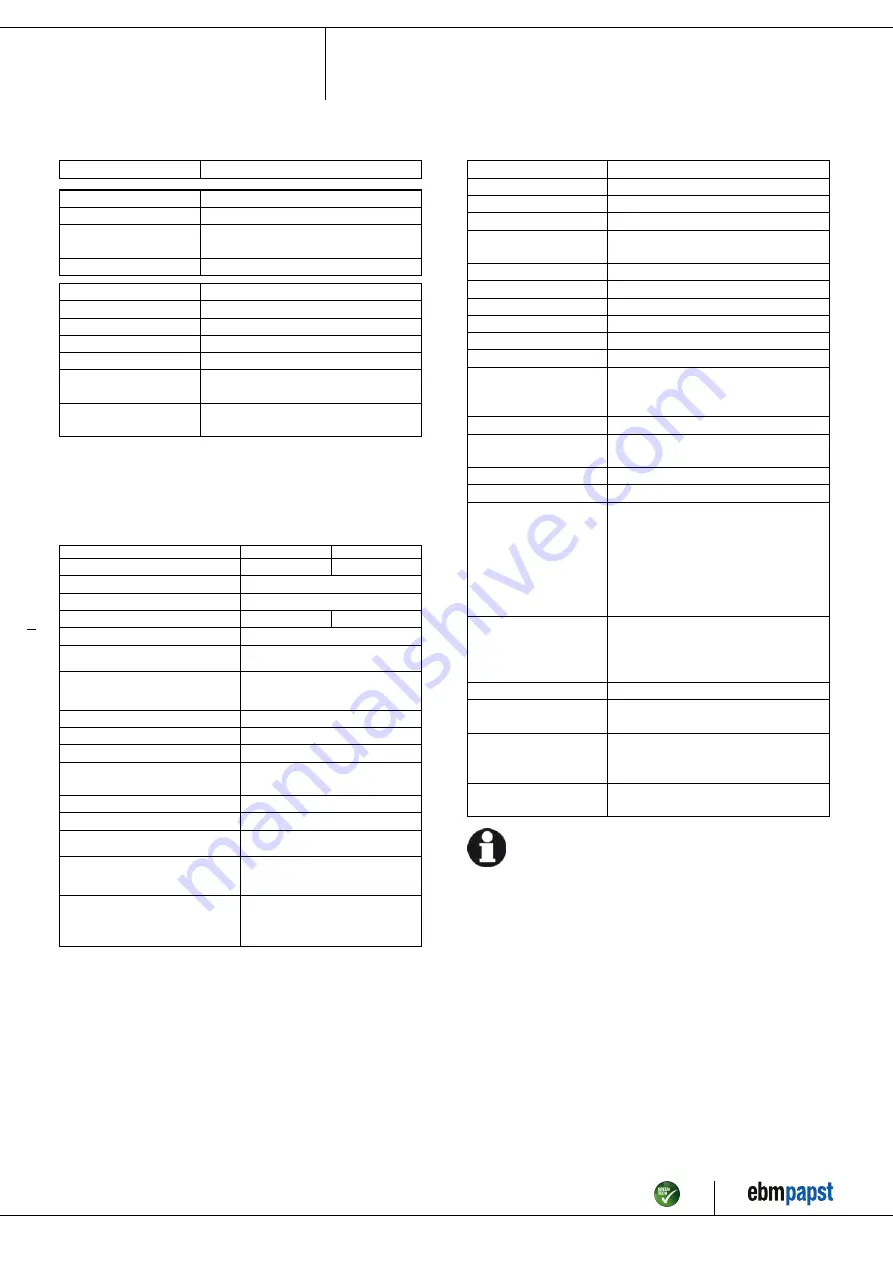

3.2 Nominal data

Motor

M1G055-DF

Phase

1~

Nominal voltage / VAC

230

Nominal voltage

range / VAC

200 .. 240

Frequency / Hz

50/60

Type of data definition

ml

Speed (rpm) / min

-1

1840

Power input / W

165

Current draw / A

1.20

Min. back pressure / Pa

115

Min. ambient

temperature / °C

-25

Max. ambient

temperature / °C

50

ml = Max. load · me = Max. efficiency · fa = Running at free air

cs = Customer specs · cu = Customer unit

Subject to alterations

3.3 Data in accordance with ecodesign regulation EU 327/

2011

Actual

Request 2015

01 Overall efficiency η

es

/ %

33.8

32.8

02 Measurement category

A

03 Efficiency category

Static

04 Efficiency grade N

45

44

05 Variable speed drive

Yes

06 Year of manufacture

The year of manufacture is specified on the

rating plate on the product.

07 Manufacturer

ebm-papst Mulfingen GmbH & Co. KG

County court Stuttgart · HRA 590344

D-74673 Mulfingen

08 Type

D1G146-LV03-06

09 Power input P

ed

/ kW

0.16

09 Air flow q

v

/ m³/h

400

09 Pressure increase total p

fs

/

Pa

448

10 Speed (rpm) n / min

-1

2885

11 Specific ratio

*

1.00

12 Recycling/disposal

Information on recycling and disposal is

provided in the operating instructions.

13 Maintenance

Information on installation, operation and

maintenance is provided in the operating

instructions.

14 Additional components

Components used to calculate the energy

efficiency that are not apparent from the

measurement category are detailed in the

CE declaration.

*

Specific ratio = 1 + p

fs

/ 100 000 Pa

Data definition with optimum efficiency. The indicated efficiency values for obtaining

conformity with the Ecodesign Directive EU 327/2011 were achieved with defined air

conduction components (e.g. inlet nozzles). The dimensions are to be requested from ebm-

papst. If other air guide geometries are used on the installation side, the ebm-papst

evaluation loses its validity/conformity must be confirmed again. The product does not fall

within the scope of Regulation (EU) 2019/1781 due to the exception specified in Article 2(2a)

(motors completely integrated into a product).

3.4 Technical features

Mass

2.467 kg

Size

146 mm

Motor size

55

Surface of rotor

Thick layer passivated

Material of electronics

housing

PP plastic

Material of impeller

Sheet steel, galvanised

Housing material

PP plastic

Motor suspension

Motor mounted anti-vibration on both sides

Direction of rotation

Counter-clockwise, seen on rotor

Type of protection

IP20

Insulation class

"B"

Humidity (F) /

environmental

protection class (H)

H0 - dry environment

Mounting position

Any

Condensation

drainage holes

None, open rotor

Operation mode

S1

Motor bearing

Ball bearing

Technical features

- Fault output (open collector)

- Motor current limit

- Soft start

- PWM control input

- Control interface with SELV potential

safely disconnected from the mains

- Over-temperature protected motor

Touch current acc.

IEC 60990 (measuring

network Fig. 4, TN

system)

<= 3.5 mA

Electrical connection

Connector with connection line

Motor protection

Thermal overload protector (TOP) wired

internally

Protection class

Built-in component, safety classification

after installation in accordance with

intended use

Product conforming

to standard

EN 60335-1; CE

For cyclic speed loads, note that the rotating parts of the device

are designed for maximum one million load cycles. If you have

specific questions, contact ebm-papst for support.

;

Use the device in accordance with its protection type.

Notes on surface quality

The surfaces of the products conform to the generally applicable industrial

standard. The surface quality may vary during the production period.

Strength, dimensional stability and dimensional accuracy are not affected

by this.

The colour pigments of the paints used react perceptibly to UV light over

the course of time. To prevent the formation of patches and fading, the

product is to be protected against UV radiation. Changes in colour are

not a reason for complaint and are not covered by the warranty. UV

radiation in the frequency range and the intensity of natural solar radiation

has no effect on the technical properties of the products.

Item no. 54195-5-9970 · ENG · Revision 225511 · Release 2022-01-11 · Page 5 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com