Operating instructions

K3G310-AZ88-02

Translation of the original operating instructions

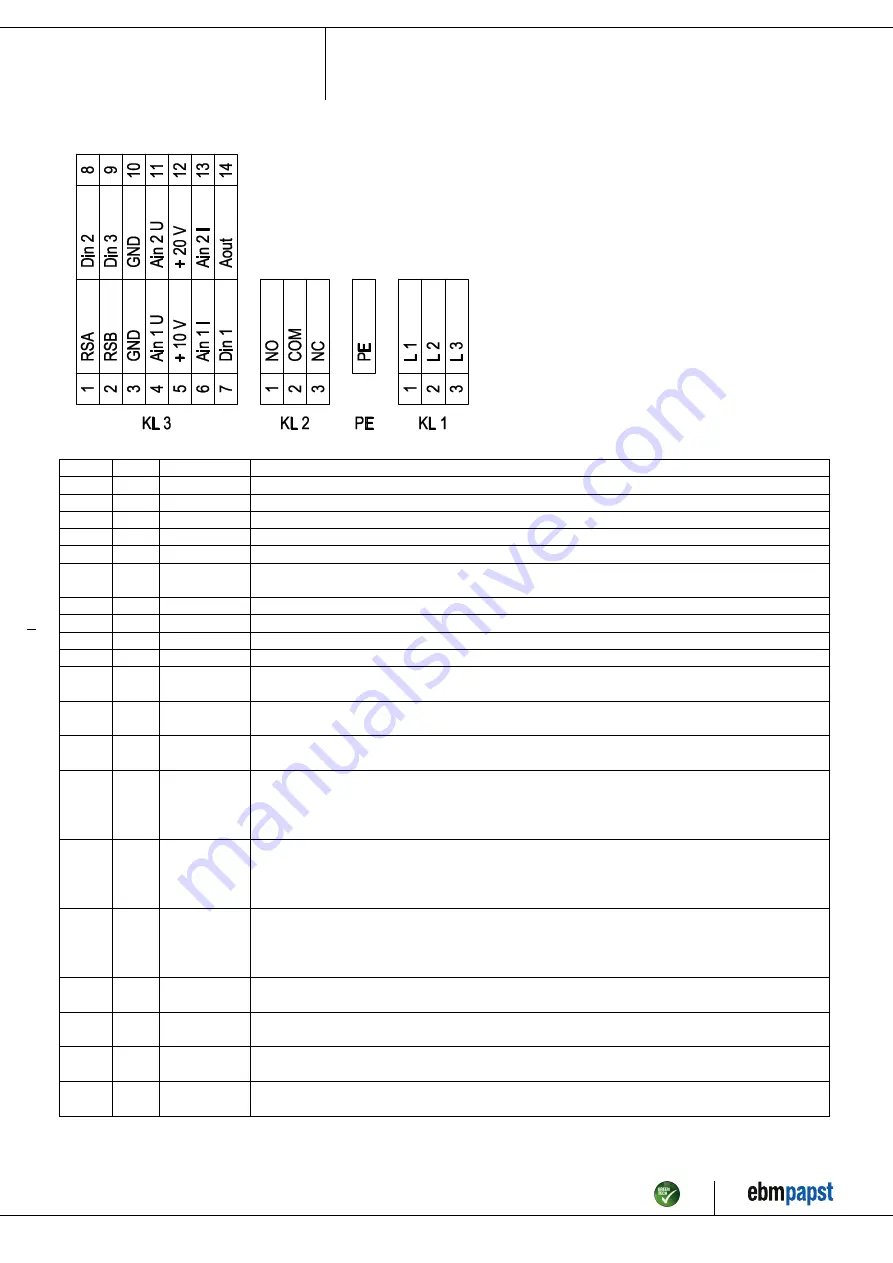

4.5 Connection screen

No.

Conn.

Designation

Function / assignment

KL 1

1

L1

Mains supply connection, supply voltage 3~380-480 VAC; 50/60 Hz

KL 1

2

L2

Mains supply connection, supply voltage 3~380-480 VAC; 50/60 Hz

KL 1

3

L3

Mains supply connection, supply voltage 3~380-480 VAC; 50/60 Hz

PE

PE

Earth connection, PE connection

KL 2

1

NO

Status relay, floating status contact; normally open; close with error

KL2

2

COM

Status relay; floating status contact; changeover contact; common connection; contact rating 250 VAC / max.

2 A (AC1) / min. 10 mA

KL2

3

NC

Status relay, floating status contact; break with error

KL 3

1

RSA

Bus connection RS-485, RSA, MODBUS RTU; SELV

KL 3

2

RSB

Bus connection RS-485, RSB, MODBUS RTU; SELV

KL 3

3 / 10

GND

Signal ground for control interface; SELV

KL 3

4

Ain1 U

Analogue input 1, set value: 0-10 V, Ri = 100 kΩ, parametrisable curve, only usable as alternative to input

Ain1; SELV

KL 3

5

+ 10 V

Fixed voltage output 10 VDC, +10 V ±3%, max. 10 mA, short-circuit-proof, power supply for external

devices (e.g. potentiometer), SELV

KL 3

6

Ain1 I

Analogue input 1, set value: 4-20 mA; Ri = 100 Ω, parametrisable curve, only usable as alternative to input

Ain1 U; SELV

KL 3

7

Din1

Digital input 1: enabling of electronics,

enabling: open pin or applied voltage 5-50 VDC

disabling: bridge to GND or applied voltage <1 VDC

reset function: triggers software reset after a level change to <1 VDC; SELV

KL 3

8

Din2

Digital input 2: parameter set switch 1/2, according to EEPROM setting, the valid/used parameter set can be

selected via bus or via digital input DIN2.

Parameter set 1: open pin or applied voltage 5-50 VDC

Parameter set 2: bridge to GND or applied voltage <1 VDC; SELV

KL 3

9

Din3

Digital input 3: controller function of integrated controller, according to EEPROM setting, the controller function

of the integrated controller is normally/inversely selectable per bus or per digital input

normal: open pin or applied voltage 5-50 VDC

inverse: bridge to GND or applied voltage <1 VDC; SELV

KL 3

11

Ain2 U

Analogue input 2, actual value: 0-10 V, Ri = 100 kΩ, parametrisable curve, only usable as alternative to input

Ain2; SELV

KL 3

12

+ 20 V

Fixed voltage output 20 VDC, +20 V +25/-10%, max. 50 mA, short-circuit-proof, power supply for external

devices (e.g. sensors); SELV

KL 3

13

Ain2 I

Analogue input 2, actual value: 4-20 mA, Ri = 100 Ω, parametrisable curve, only usable as alternative to

input Ain2 U; SELV

KL 3

14

Aout

Analogue output 0-10 VDC, max. 5 mA, output of the current motor level control coefficient / motor speed

parametrisable curve; SELV

Item no. 50655-5-9970 · ENG · Revision 82542 · Release 2014-05-08 · Page 9 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com