Operating instructions

K3G400-HB41-01

Translation of the original operating instructions

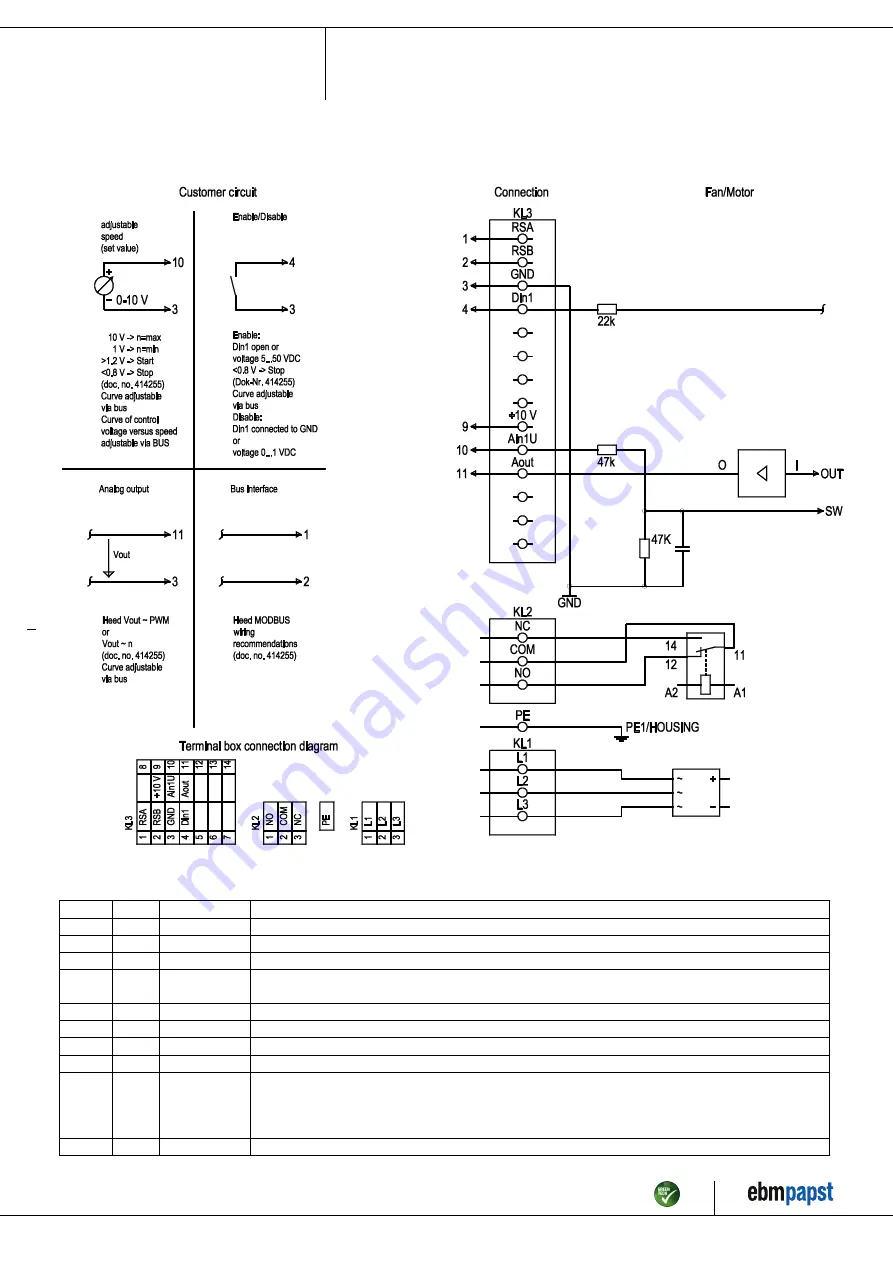

4.5 Connection diagram

No.

Conn.

Designation

Function/assignment

KL 1

1, 2, 3

L1, L2, L3

Power supply, phase, see nameplate for voltage range

PE

PE

PE

Protective earth

KL2

1

NO

Status relay, floating status contact, option 1: make for failure, option 2: make for error for run monitor

KL2

2

COM

Status relay, floating status contact, common connection, contact rating 250 VAC / 2 A (AC1) / min. 10 mA;

basic insulation on supply side and reinforced insulation on control interface side

KL2

3

NC

Status relay, floating status contact, option 1: break for failure, option 2: break for error message for run monitor

KL 3

1

RSA

RS485 interface for MODBUS, RSA; SELV

KL 3

2

RSB

RS485 interface for MODBUS, RSB; SELV

KL 3

3

GND

Reference ground for control interface; SELV

KL 3

4

Din1

Digital input 1: enable electronics,

enable: pin open or applied voltage 5-50 VDC

disable: bridge to GND or applied voltage < 1 VDC

reset function: triggers software reset after a level change to < 1 VDC; SELV

KL 3

-

-

-

Item no. 56857-5-9970 · ENU · Change 260705 · Approved 2022-09-01 · Page 10 / 15

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com