Operating instructions

K3G630-AP01-90

`

II 2G Ex db eb ib IIB T3 Gb

IBExU14ATEX1122 X /05

`

Translation of the original operating instructions

54007-4-8670

7. MAINTENANCE, MALFUNCTIONS, POSSIBLE

CAUSES AND REMEDIES

Do not perform any repairs on the device. Send it to ebm-papst for repair

or replacement.

When performing maintenance work on the fan, e.g. when cleaning the

fan impeller, the fan must be stationary and the electrical circuit must be

interrupted and safeguarded against unintentional re-starting.

;

Wait until the device comes to a stop.

WARNING

Live terminals and connections even with device

switched off

Electric shock

→ When shutting off the device, note Chapter 5.8 Switching off

the device.

→ Wait five minutes after disconnecting the voltage at all

poles before opening the device.

CAUTION

If control voltage or a stored speed set value is applied,

the motor will restart automatically, e.g. after mains

failure.

Risk of injury

→ When working on the device, switch off the line voltage and

ensure that it cannot be switched back on.

→ Wait until the device comes to a stop.

→ Keep out of the device danger zone.

→ After performing work on the device, remove any tools

used or other objects from the fan air paths.

If the device is out of use for over four months, we recommend

switching it on for at least three hours at full speed to allow any

condensation to evaporate and to move the bearings.

;

Carry out inspections and cleaning as appropriate for the Ex marking

so that no dirt deposits form.

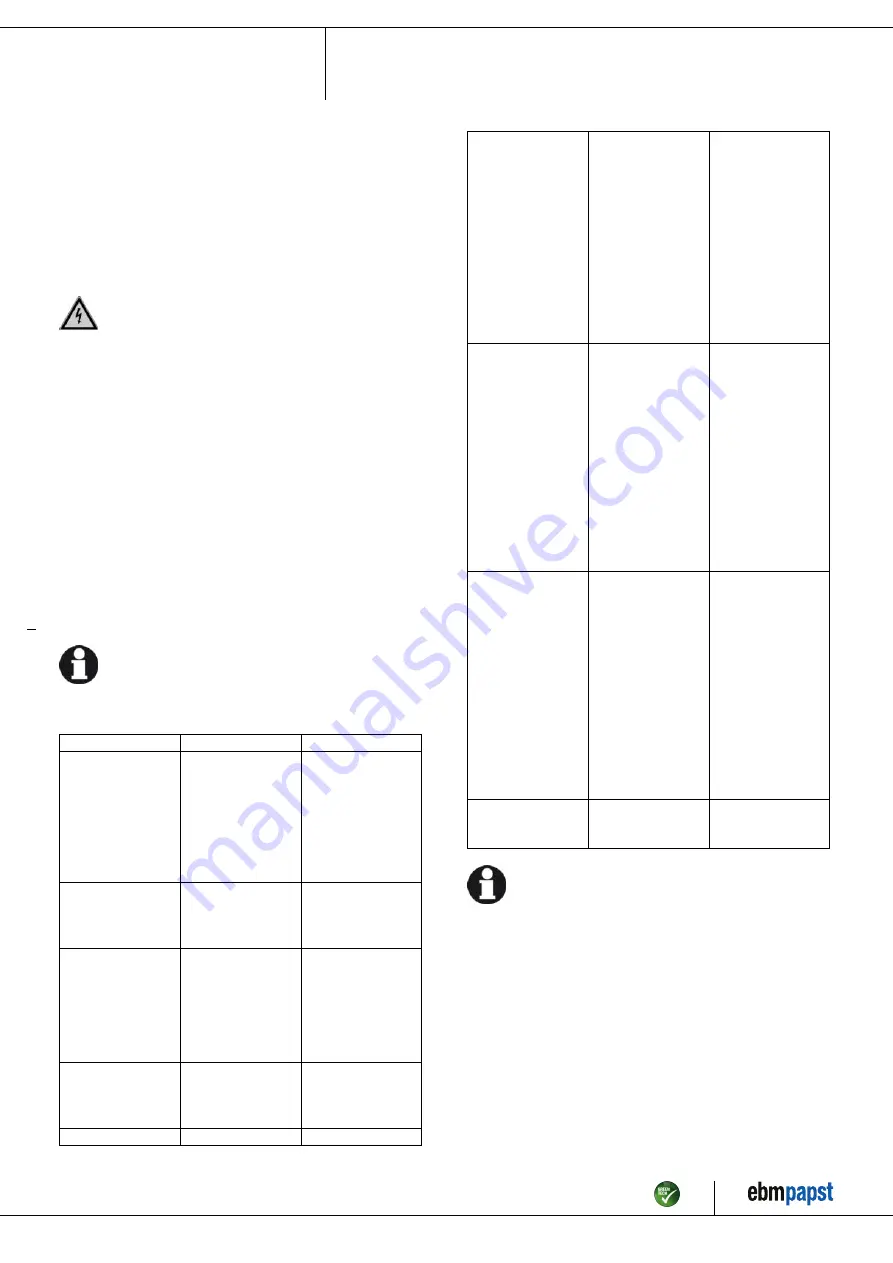

Malfunction/fault

Possible cause

Possible remedy

Impeller not

running smoothly

Imbalance in rotating

parts

Clean the device;

replace if imbalance

persists after

cleaning. Make sure

no weight clips are

moved, damaged or

removed during

cleaning.

Motor not turning

Mechanical blockage

Switch off, isolate

from supply and

remove mechanical

blockage.

Line voltage faulty

Check line voltage,

restore power

supply. Attention! The

error message resets

automatically. Device

restarts automatically

without warning.

Faulty connection

Isolate from supply,

correct connection;

see connection

diagram.

Broken motor winding Replace device

Deficient cooling

Improve cooling. Let

the device cool down.

To reset the error

message, switch off

the line voltage for at

least 25 s and then

switch it on again.

Alternatively, reset

the error message by

applying a control

signal of < 0.5 V to

Din1 or by shorting

Din1 to GND.

Ambient temperature

too high

Reduce the ambient

temperature. Let the

device cool down.

To reset the error

message, switch off

the line voltage for at

least 25 s and then

switch it on again.

Alternatively, reset

the error message by

applying a control

signal of < 0.5 V to

Din1 or by shorting

Din1 to GND.

Impermissible point of

operation (e.g.

excessive load, back

pressure too high)

Correct the operating

point. Let the device

cool down.

To reset the error

message, switch off

the line voltage for at

least 25 s and then

switch it on again.

Alternatively, reset

the error message by

applying a control

signal of < 0.5 V to

Din1 or by shorting

Din1 to GND.

Terminal box

fastening screws

broken while closing

Replace device

In the event of further malfunctions, contact ebm-papst.

7.1 Cleaning

NOTE

Damage to the device during cleaning

Malfunction possible

→ Do not clean the device using a water jet or high-pressure

cleaner.

→ Do not use any acid, alkali or solvent-basedcleaning

agents.

→ Do not use any pointed or sharp-edged objects for cleaning

Item no. 54007-5-9970 · ENU · Change 272968 · Approved 2022-11-23 · Page 17 / 18

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com