Operating instructions

K3G630-AP01-90

`

II 2G Ex db eb ib IIB T3 Gb

IBExU14ATEX1122 X /05

`

Translation of the original operating instructions

54007-4-8670

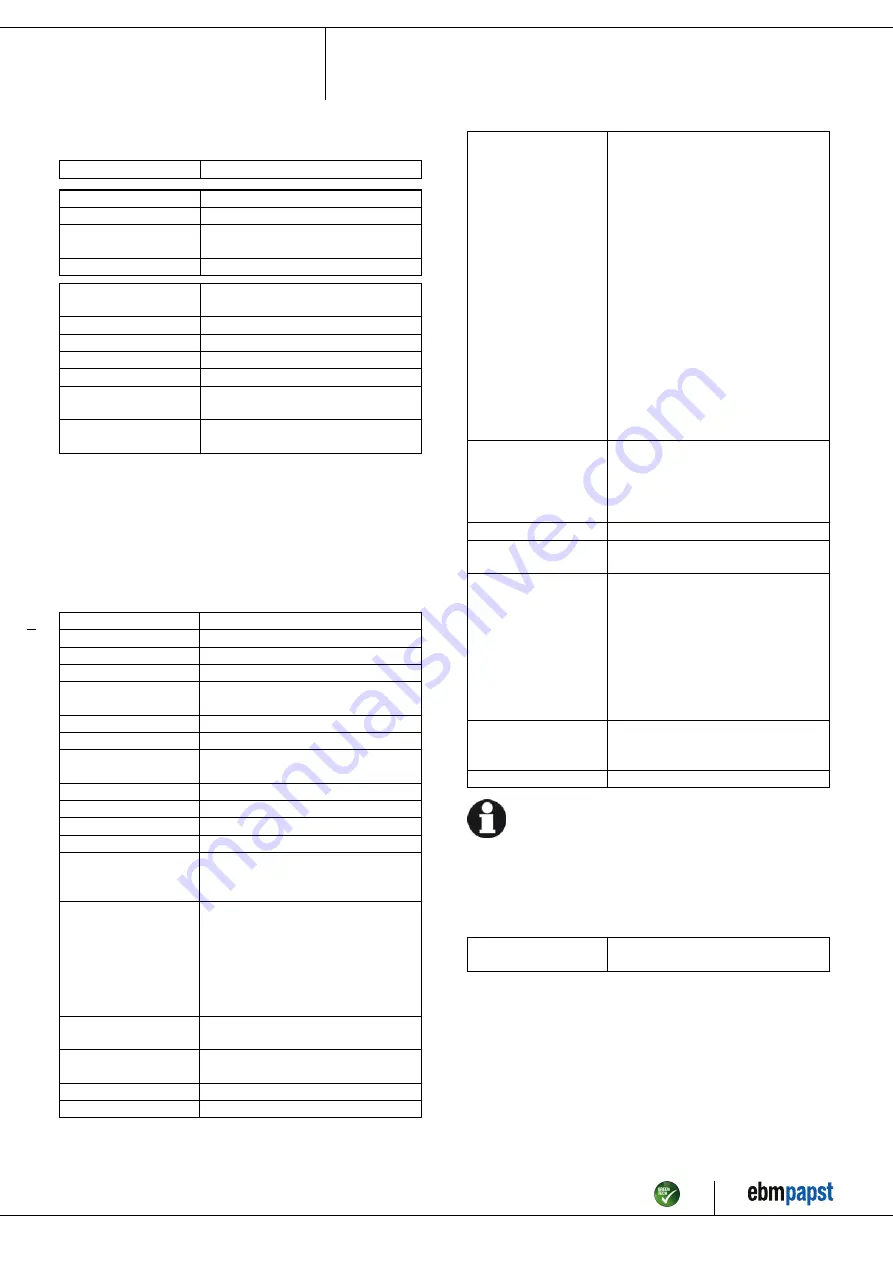

4.2 Nominal data

Motor

M3G150-NA

Phase

3~

Nominal voltage / VAC

400

Nominal voltage

range / VAC

380 .. 440

Frequency / Hz

50/60

Method of obtaining

data

ml

Status

prelim.

Speed (rpm) / min

-1

1130

Power consumption / W

2970

Current draw / A

4.6

Min. ambient

temperature / °C

-40

Max. ambient

temperature / °C

50

ml = Max. load · me = Max. efficiency · fa = Free air

cs = Customer specification · ce = Customer equipment

Subject to change

Occasional start-up at temperatures between -40 °C and -25 °C is

permitted. For continuous operation at ambient temperatures below -25

°C (such as refrigeration applications), a fan design with special low-

temperature bearings must be used.

4.3 Technical description

Weight

89.3 kg

Size

630 mm

Motor size

150

Rotor surface

Painted black

Electronics housing

material

Die-cast aluminum, painted black

Impeller material

Sheet aluminum

Inlet nozzle material

Sheet aluminum

Support structure

material

Sheet steel, galvanized

Number of blades

7

Direction of rotation

Clockwise, viewed toward rotor

Degree of protection

IP44

Insulation class

"F"

Moisture (F) /

Environmental (H)

protection class

H1

Ambient temperature

note

Occasional start-up at temperatures

between -40°C and -25°C is permitted.

For continuous operation at ambient

temperatures below -25°C (such as

refrigeration applications), use must be

made of a fan design with special low-

temperature bearings.

Installation position

Shaft horizontal (base mounting only) or

rotor on bottom; rotor on top not permitted

Condensation

drainage holes

On rotor side

Mode

S1

Motor bearing

Ball bearing

Technical features

- Output 10 VDC, max. 10 mA

- Output 20 VDC, max. 50 mA

- Output for slave 0-10 V

- Operation and alarm display

- Input for sensor 0-10 V or 4-20 mA

- External 24 V input (parameter setting)

- External release input

- Alarm relay

- Integrated PID controller

- Motor current limitation

- PFC, passive

- RS-485 MODBUS-RTU

- Soft start

- Control input 0-10 VDC / PWM

- Temperature derating

- Thermal overload protection for

electronics/motor

- Line undervoltage / phase failure

detection

Touch current

according to IEC

60990 (measuring

circuit Fig. 4, TN

system)

<= 3.5 mA

Electrical hookup

Terminal box

Motor protection

Reverse polarity and locked-rotor

protection

Protection class

assignment

I; If a protective earth is connected by

the customer

This component for installation may

have several local protection classes.

This information relates to this

component’s basic design.

The final protection class is based on

the component’s intended installation and

connection.

Conformity with

standards

EN 14986; EN 60079-0; EN 60079-1;

EN 60079-7; EN 60079-11; EN 61800-5-

1; CE

Approval

II 2G; EAC

With regard to cyclic speed loads, note that the rotating parts of

the device are designed for a maximum of one million load

cycles. If you have special questions, consult ebm-papst for

support.

4.4 Mounting data

;

Secure the screws against unintentional loosening (e.g. use self-

locking screws).

Strength class of

screws

10.9

Any further mounting data required can be taken from the product drawing.

Item no. 54007-5-9970 · ENU · Change 272968 · Approved 2022-11-23 · Page 8 / 18

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com