Operating instructions

K3G710-PV05-02

Translation of the original operating instructions

;

Check the device for transport damage. Damaged devices are not to

be installed.

;

Install the undamaged device in accordance with your application.

4.1.1 Installation of RadiPac fan

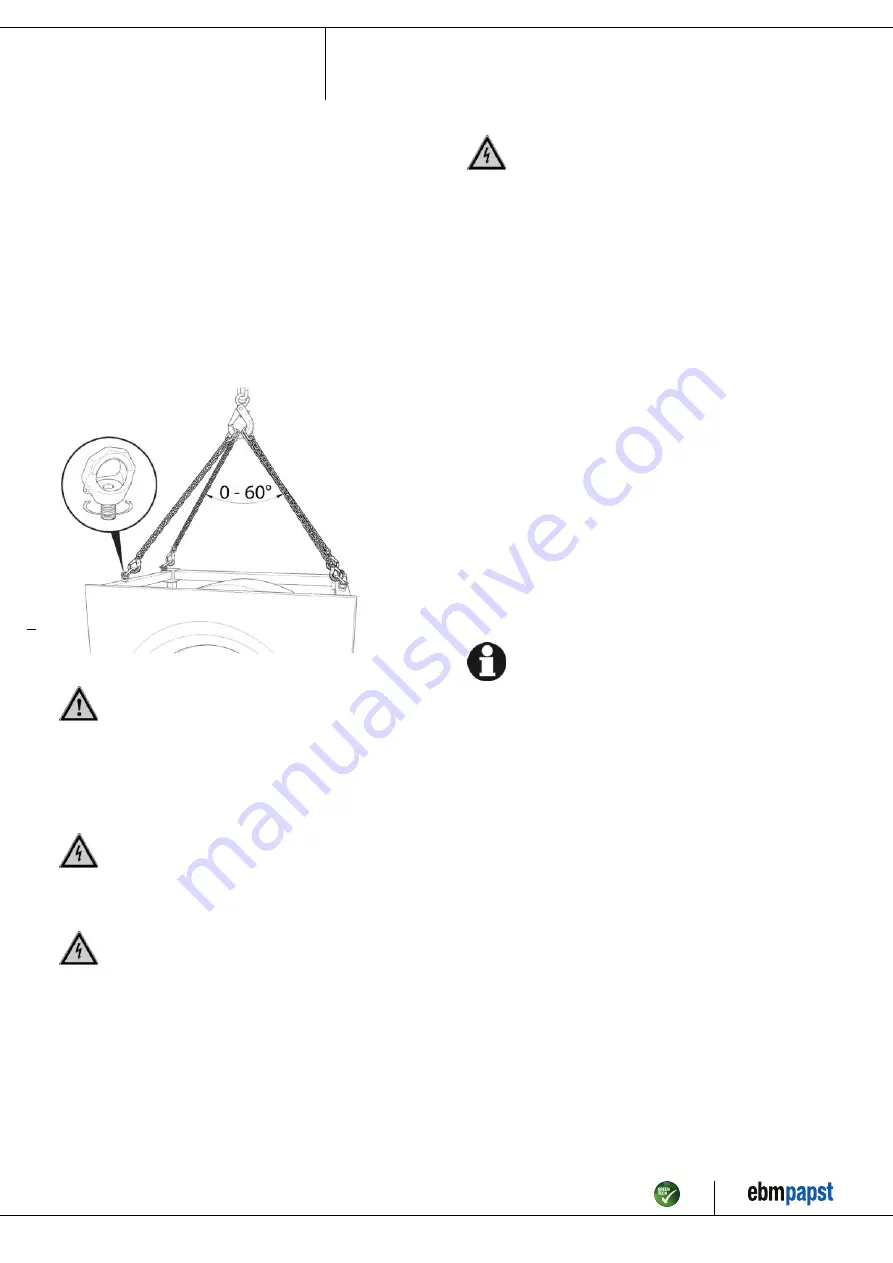

Use is always to be made of appropriate hoisting equipment and a

suitable lifting device when transporting the RadiPac for installation

purposes. Use only suitable ropes or chains (see Chapter 3.4 Technical

description for product weight). To attach the hoisting equipment, use four

M10 eye bolts that can turn under load; screw the eye bolts into the

tapped holes provided. For fans not provided with tapped holes, use the

existing holes and lock the threaded bolts that can turn (M8 or M10) on

the underside with a nut. Do not use standard DIN 580 eye bolts. Note

that the angle between the ropes or chains may be between 0° and 60°.

During transportation, an acceleration of 2 g must not be exceeded.

Fig. 2: Illustration showing transport of RadiPac fan

CAUTION

Possible damage to the device

If the device slips during installation, serious damage can result.

→ Ensure that the device is securely positioned at its place of

installation until all fastening screws have been tightened.

●

The fan must not be strained on fastening.

4.2 Electrical connection

DANGER

Voltage on the device

Electric shock

→ Always connect a protective earth first.

→ Check the protective earth.

DANGER

Faulty insulation

Risk of fatal injury from electric shock

→ Use only cables that meet the specified installation

regulations for voltage, current, insulation material, capacity,

etc.

→ Route cables so that they cannot be touched by any

rotating parts.

DANGER

Electrical charge (>50 µC) between phase conductor and

protective earth connection after switching off supply

with multiple devices connected in parallel.

Electric shock, risk of injury

→ Ensure sufficient protection against accidental contact.

Before working on the electrical hookup, short the supply

and PE connections.

CAUTION

Voltage

The fan is a built-in component and has no disconnecting switch.

→ Only connect the fan to circuits that can be switched off with

an all-pole disconnection switch.

→ When working on the fan, secure the system/machine in

which the fan is installed so as to prevent it from being

switched back on.

NOTE

Device malfunctions possible

Route the device's control lines separately from the supply line.

→ Maintain the greatest possible clearance.

Recommendation: clearance > 10 cm (separate cable

routing)

NOTE

Water ingress into wires or cables

Water ingress at the customer end of the cable can damage the

device.

→ Make sure the end of the cable is connected in a dry

environment.

Only connect the device to circuits that can be switched off with

an all-pole disconnection switch.

4.2.1 Requirements

;

Check whether the information on the nameplate matches the

connection data.

;

Before connecting the device, make sure the power supply matches

the device voltage.

;

Only use cables designed for the current level indicated on the

nameplate.

For determining the cross-section, note the sizing criteria according

to EN 61800-5-1. The protective earth must have a cross-section

equal to or greater than that of the phase conductor.

We recommend the use of 105 °C cables. Ensure that the minimum

cable cross-section is at least

AWG 26 / 0.13 mm².

Protective earth contact resistance according to EN 61800-5-1

Compliance with the resistance specifications according to EN 61800-5-

1 for the protective earth connection circuit must be verified in the end

application. Depending on the installation situation, it may be necessary

to connect an additional protective earth conductor by way of the extra

protective earth terminal provided on the device. The protective earth

terminal is located on the housing and provided with a protective earth

symbol and a hole.

Item no. 55980-5-9970 · ENU · Change 212420 · Approved 2020-02-17 · Page 7 / 15

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com