Operating instructions

R2E225-RA92-09

Translation of the original operating instructions

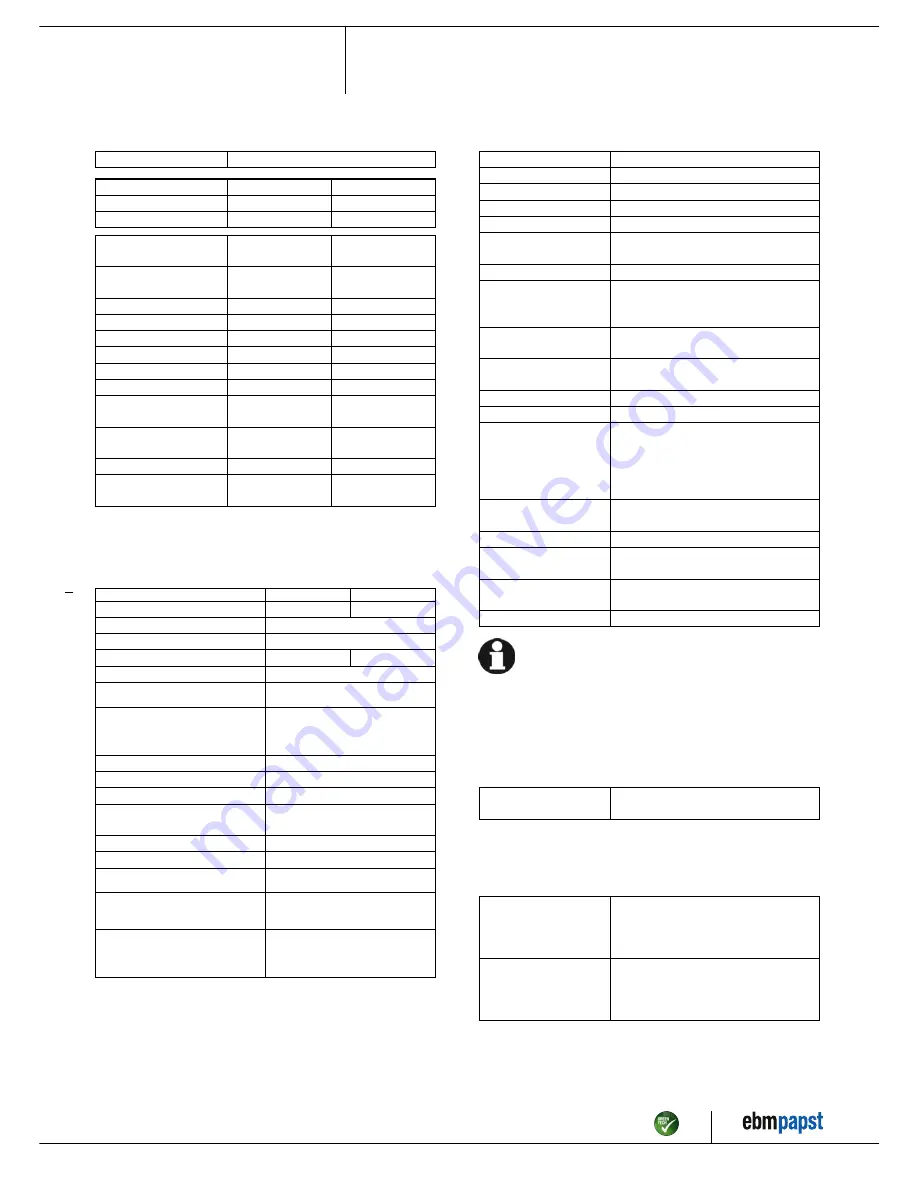

3.2 Nominal data

Motor

M2E068-DF

Phase

1~

1~

Nominal voltage / VAC

230

230

Frequency / Hz

50

60

Method of obtaining

data

ml

ml

Valid for approval/

standard

CE

CE

Speed / min

-1

2500

2600

Power consumption / W

155

210

Current draw / A

0.68

0.92

Capacitor / µF

3.5

3.5

Capacitor voltage / VDB

450

450

Min. back pressure / Pa

0

0

Min. ambient

temperature / °C

-25

-25

Max. ambient

temperature / °C

70

65

Starting current / A

1.25

1.2

Max. safe operating

speed / min

-1

3600

@ 80 °C

3600

@ 80 °C

ml = Max. load · me = Max. efficiency · fa = Free air

cs = Customer specification · ce = Customer equipment

Subject to change

3.3 Data according to ErP Directive

Actual

Req. 2015

01 Overall efficiency η

es

/ %

42.5

42.5

02 Measurement category

A

03 Efficiency category

Static

04 Efficiency grade N

62

62

05 Variable speed drive

No

06 Year of manufacture

The year of manufacture is specified on the

product's rating label.

07 Manufacturer

ebm-papst Mulfingen GmbH & Co. KG

Amtsgericht (court of registration) Stuttgart ·

HRA 590344

D-74673 Mulfingen

08 Type

R2E225-RA92-09

09 Power consumption P

e

/ kW

0.14

09 Air flow q

v

/ m³/h

705

09 Pressure increase total p

sf

/

Pa

320

10 Speed n / min

-1

2560

11 Specific ratio

*

1.00

12 Recycling/disposal

Information on recycling and disposal is

provided in the operating instructions.

13 Maintenance

Information on installation, operation and

maintenance is provided in the operating

instructions.

14 Additional components

Components used to calculate the energy

efficiency that are not apparent from the

measurement category are detailed in the

CE declaration.

*

Specific ratio = 1 + p

fs

/ 100 000 Pa

Data obtained at optimum efficiency level. The ErP data is determined using a motor-impeller

combination in a standardized measurement setup.

3.4 Technical description

Fan size

225 mm

Rotor surface

Painted black

Impeller material

PA6 plastic, glass-fiber reinforced

Number of blades

7

Direction of rotation

Clockwise, viewed toward rotor

Degree of protection

IP44; installation- and position-dependent

as per EN 60034-5

Insulation class

"F"

Moisture (F) /

Environmental (H)

protection class

H0+

Installation position

Shaft horizontal or rotor on bottom; rotor

on top on request

Condensation

drainage holes

On rotor side

Mode

S1

Motor bearing

Ball bearing

Touch current

according to IEC

60990 (measuring

circuit Fig. 4, TN

system)

< 0.75 mA

Motor protection

Thermal overload protector (TOP)

internally connected

with cable

Variable

Protection class

I (with customer connection of protective

earth)

Conformity with

standards

EN 60335-1; CE

Approval

EAC; CCC

With regard to cyclic speed loads, note that the rotating parts of

the device are designed for a maximum of one million load

cycles. If you have special questions, consult ebm-papst for

support.

3.5 Mounting data

For screw clearance, see Chapter 3.1 Product drawing

;

Secure the screws against unintentional loosening (e.g. use self-

locking screws).

Strength class of

screws

8.8

Any further mounting data required can be taken from the product drawing.

3.6 Transport and storage conditions

;

Use the device in accordance with its degree of protection.

Max. permitted

ambient temp. for

motor (transport/

storage)

+ 80 °C

Min. permitted

ambient temp. for

motor (transport/

storage)

- 40 °C

Item no. 10989-5-9970 · ENU · Change 89188 · Approved 2016-04-18 · Page 5 / 9

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com