Operating instructions

R3G250-PR02-J1

Translation of the original operating instructions

4.3 Connecting the cables

The device has external leads.

;

First connect the "PE" (protective earth).

●

Connect the cables according to your application. When doing so,

observe Chapter 4.5 Connection diagram.

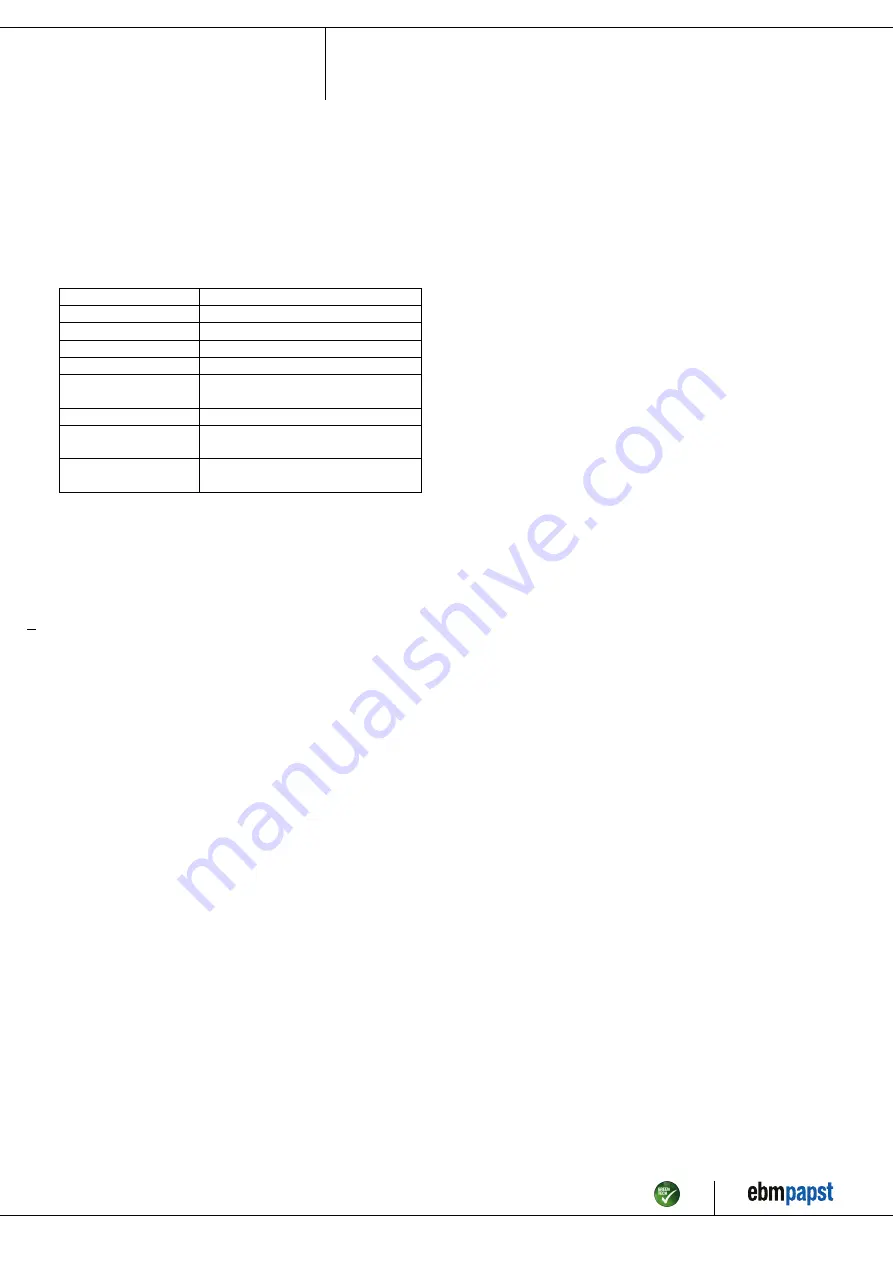

4.4 Factory settings

Factory settings made for the device by ebm-papst.

Mode parameter set 1

PWM control

Mode parameter set 2

PWM control

Fan/device address

01

Max. PWM / %

100

Min. PWM / %

5

Save set value to

EEPROM

Yes

Set value requirement

Analog (linear)

Direction of action

parameter set 1

Positive (heating)

Direction of action

parameter set 2

Positive (heating)

Item no. 54444-5-9970 · ENU · Change 229573 · Approved 2021-06-09 · Page 9 / 14

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com