Operating instructions

R3G250-RR09-P1

Translation of the original operating instructions

NOTE

Water ingress into wires or cables

Water ingress at the customer end of the cable can damage the

device.

→ Make sure the end of the cable is connected in a dry

environment.

4.2.1 Requirements

;

Check whether the information on the nameplate matches the

connection data.

;

Before connecting the device, make sure the power supply matches

the device voltage.

;

Only use cables designed for the current level indicated on the

nameplate.

For determining the cross-section, note the sizing criteria according

to EN 61800-5-1. The protective earth must have a cross-section

equal to or greater than that of the phase conductor.

We recommend the use of 105 °C cables. Ensure that the minimum

cable cross-section is at least

AWG 26 / 0.13 mm².

Operate the device with an electrically isolated power supply.

4.3 Connecting the cables

The device has external leads.

;

First connect the "PE" (protective earth).

●

Connect the cables according to your application. When doing so,

observe Chapter 4.5 Connection diagram.

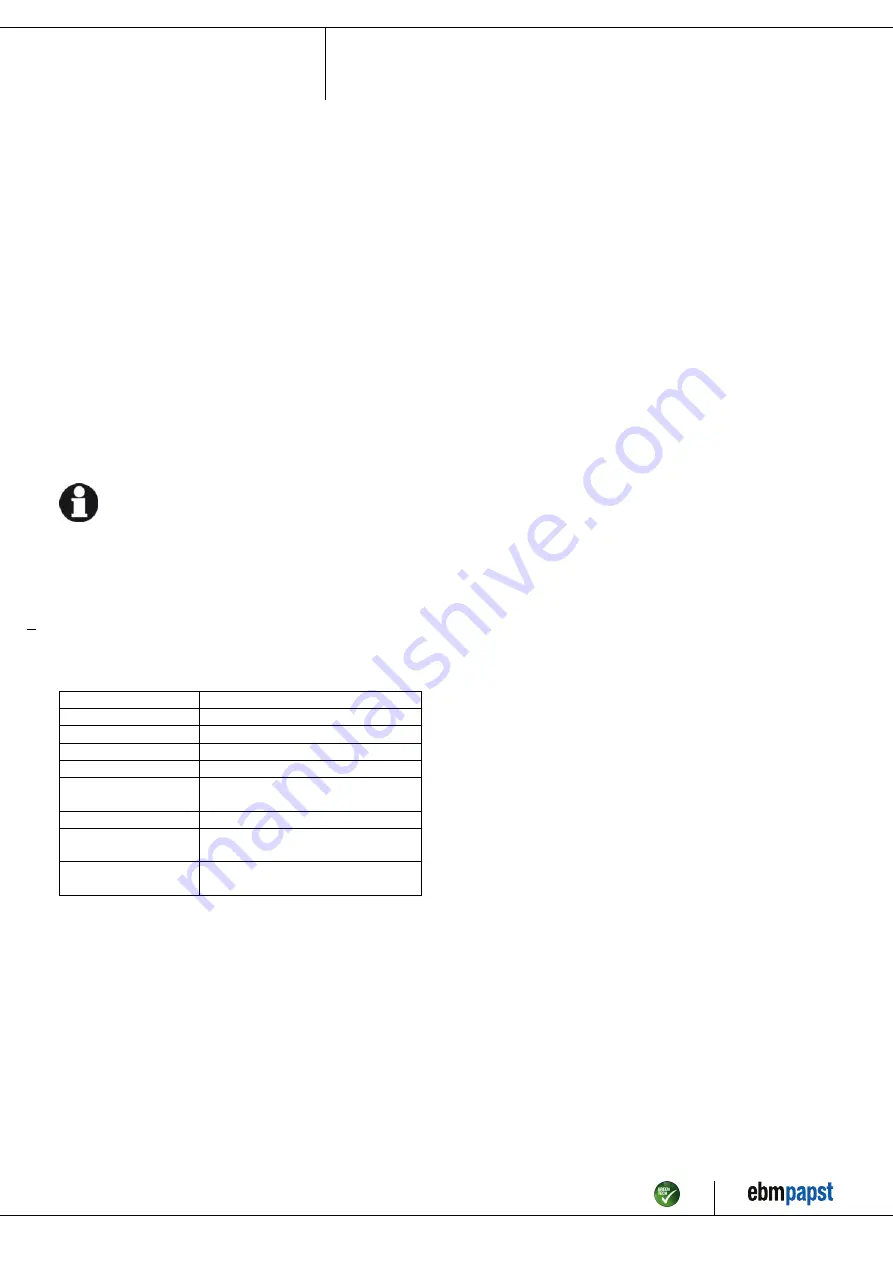

4.4 Factory settings

Factory settings made for the device by ebm-papst.

Mode parameter set 1

PWM control

Mode parameter set 2

PWM control

Fan/device address

01

Max. PWM / %

100

Min. PWM / %

10

Save set value to

EEPROM

No

Set value requirement

Analog (linear)

Direction of action

parameter set 1

Positive (heating)

Direction of action

parameter set 2

Positive (heating)

Item no. 53889-5-9970 · ENU · Change 235485 · Approved 2021-12-14 · Page 8 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com