Operating instructions

R3G500-DA25-05

Translation of the original operating instructions

6. MAINTENANCE, MALFUNCTIONS, POSSIBLE

CAUSES AND REMEDIES

Do not perform any repairs on your device. Send the device to ebm-

papst for repair or replacement.

WARNING

Live terminals and connections even with device

switched off

Electric shock

→ Wait five minutes after disconnecting the voltage at all poles

before opening the device.

CAUTION

If control voltage or a stored speed set value is applied,

the motor will restart automatically, e.g. after a power

failure.

Risk of injury

→ Keep out of the device’s danger zone.

→ When working on the device, switch off the line voltage

and ensure that it cannot be switched back on.

→ Wait until the device comes to a stop.

→ After working on the device, remove any tools or other

objects from the device.

NOTE

If the device is not operated for a lengthy period in installed

condition in a dry environment, it is to be started up and

operated at full speed for one hour at least every four months. If

the device is not operated for a lengthy period in installed

condition in a damp environment (e.g. outdoors), it is to be

started up and operated at full speed for at least three hours

once a month to move the bearings and allow any condensate

that may have ingressed to evaporate.

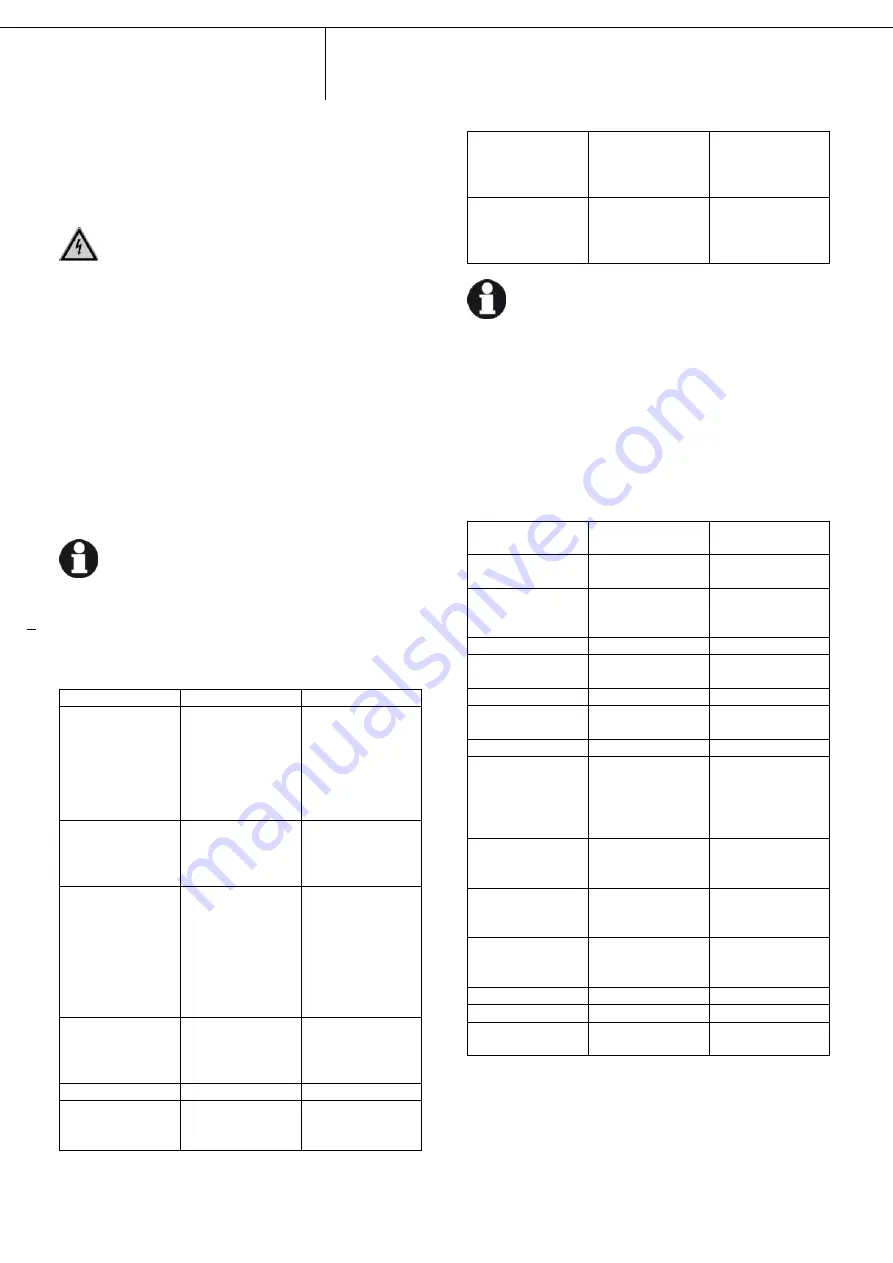

Malfunction/fault

Possible cause

Possible remedy

Impeller not

running smoothly

Imbalance in rotating

parts

Clean the device;

replace it if imbalance

persists after cleaning.

Make sure no

weight clips are

removed during

cleaning.

Motor not turning

Mechanical blockage

Switch off, isolate

from supply and

remove mechanical

blockage.

Line voltage faulty

Check line voltage,

restore power supply.

Attention! The error

message resets

automatically.

Device restarts

automatically without

warning.

Faulty connection

Isolate from supply,

correct connection;

see connection

diagram.

Broken motor winding Replace device

Inadequate cooling

Improve cooling.

Allow the device to

cool down.

Ambient temperature

too high

Reduce the ambient

temperature. Allow

the device to cool

down.

Impermissible

operating point (e.g.

back pressure too

high)

Correct the operating

point. Allow the

device to cool down.

In the event of further malfunctions, contact ebm-papst.

6.1 Warning/status codes

The LED on the electronics housing shows the motor status with various

colors and flash codes. The flash codes have a frequency of 2 Hz.

Each flash code is followed by a pause lasting 3 seconds. The following

colors are used: Green: no warning or fault. Orange: There is a warning.

No user intervention is required for warnings. Red: There is at least one

error. See the following table. If there are multiple simultaneous errors,

their associated flash codes are displayed in succession. If there are

simultaneous warnings and errors, only the errors are displayed.

6.1.1 Warning codes

Number of pulses

Motor status - LED

orange

Message at status

relay

1

Current limitation in

action

2

Line impedance too

high (DC-link voltage

unstable)

3

Power limiter in action

4

Output stage

temperature high

5

Motor temperature high

6

Temperature inside

electronics high

7

DC-link voltage low

8

Braking mode: set in

case of external drive

in opposite direction

at high speed for

lengthy period

Yes

9

Calibration of rotor

position sensor in

progress

Yes

10

Actual speed is lower

than run monitoring

speed limit

Yes

11

Open circuit at analog

input or PWM input

for the set value

Yes

13

DC-link voltage high

15

Line voltage high

16

Shake-loose function

activated