Operating instructions

R3G500-DA25-05

Translation of the original operating instructions

6.1.2 Status codes

Manual reset by "Switch off line voltage - wait briefly - switch line

voltage back on" or, if provided,

via the "Fan enable/disable" input

Number of

pulses

Motor status -

LED red

Possible cause Possible

remedy

1

Phase failure or

line undervoltage

Missing phase

Poor power

supply quality

Check line

voltage

3

Output stage

overheating

Electronics

housing

contaminated

Provide better

cooling.

Manual reset

required

4

Communication

error between

master

controller and

slave controller

External

supply applied

via Vout for

setting

parameters.

Internal error

Switch off line

voltage

- wait -

switch back on

6

Motor

overheating

Ambient

temperature too

high

Impermissible

operating point

Reduce

ambient

temperature

Correct

operating point.

Manual reset

required

7

Hall sensor error Internal error

Switch off line

voltage

- wait -

switch back on

8

Motor blocked

Mechanical

blockage

Switch off

- check safe

isolation from

supply -

check

freedom of

movement of

rotor

9

Speed limit

exceeded

-

-

11

Rotor position

sensor

calibration error

Observe

ebm-papst

replacement

instructions

Rotor position

sensor

calibration

necessary.

Notify ebm-

papst

13

DC-link

undervoltage

Line voltage not

OK

Check the line

voltage applied.

6.2 Vibration testing

Checking of fan for mechanical vibration based on ISO 14694.

Recommendation: Every 6 months. Max. vibration severity is 3.5 mm/

s, measured at the motor fastening diameter on the motor support plate in

the direction of the motor axis of rotation and perpendicular to this.

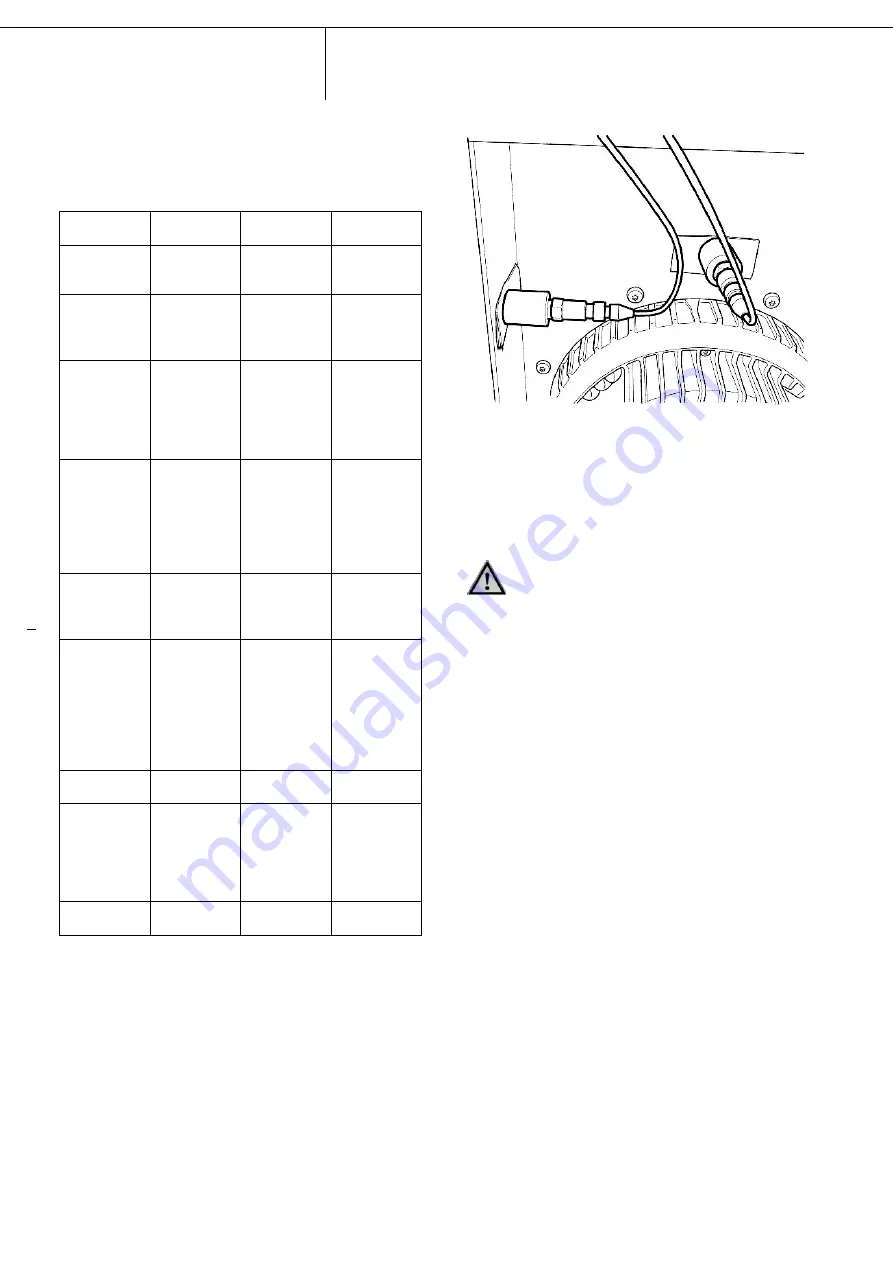

Fig. 5: Example illustrating vibration measurement. The arrangement of

the sensors depends on the device concerned and the installation

situation.

6.3 Cleaning

To ensure a long service life, check the fans regularly for proper

operation and soiling. The frequency of checking is to be adapted

accordingly depending on the degree of soiling.

DANGER

Risk of injury from rotating fan.

→ Only clean when not in motion. Do not disconnect the fan

from the power supply, just switch it off via the control input.

This will prevent start-up of the fan.

;

Dirt deposits on the motor housing can cause overheating of the motor.

;

Soiling of the impeller can cause vibration that will shorten the service

life of the fan.

;

Severe vibration can destroy the fan.

;

In such cases, switch off the fan immediately and clean it.

;

The preferred method of cleaning is dry cleaning, e.g. using

compressed air.

;

Do not use aggressive cleaning agents!

NOTE

Damage to the device during cleaning

Malfunction possible

→ Do not clean the device using a high-pressure cleaner.# Do

not use acid, alkali or solvent-based cleaning agents.

→ Do not use any pointed or sharp-edged objects for

cleaning.

;

Completely remove any cleaning agents used.

;

If severe corrosion is visible on load-bearing or rotating parts, switch

off the device immediately and replace it.

;

Repair of load-bearing or rotating parts is not permitted!

;

Operate the fan for 2 hours at maximum speed so that any water that

has ingressed can evaporate.

;

If cleaning does not eliminate vibrations, the fan may need to be

rebalanced. To have it rebalanced, contact ebm-papst.

;

The fan is equipped with maintenance-free ball bearings. The lifetime

lubrication of the ball bearings is designed for a service life of 40,000

hours.