Operating instructions

R3G630-AB06-03

Translation of the original operating instructions

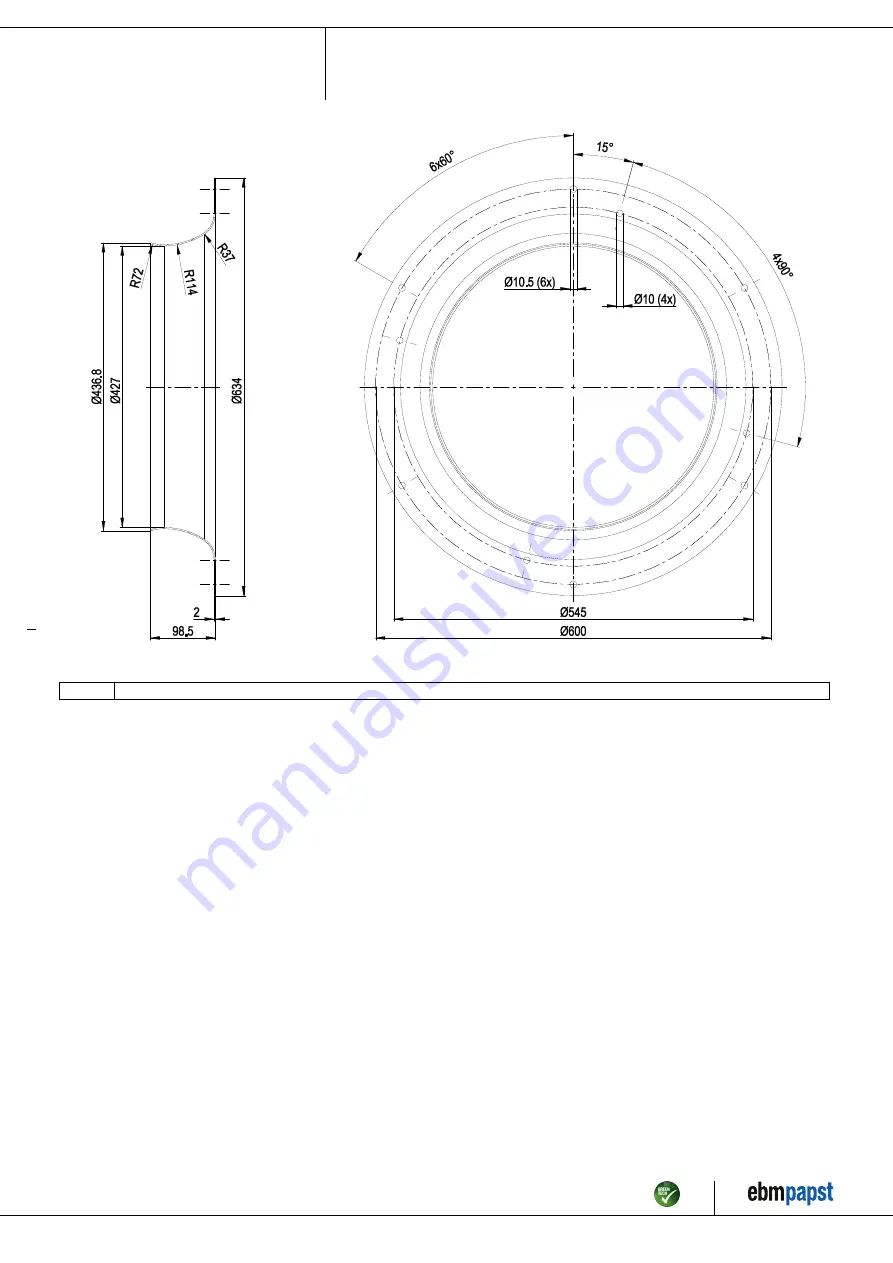

All dimensions in mm.

Inlet ring 63070-2-4013 not included in scope of delivery

Item no. 50242-5-9970 · ENU · Change 89187 · Approved 2016-04-15 · Page 5 / 13

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com