Operating instructions

R4E250-AH01-05

Translation of the original operating instructions

4.5 Checking the connections

;

Make sure that the power is off (all phases).

;

Secure it from being switched on again.

;

Check the correct fit of the connection lines.

4.6 Switch on device

The device is not to be switched on until it has been installed properly

and in accordance with its intended use, including the required protective

devices and professional electrical connection. This also applies to

devices which have already been equipped with plugs and terminals or

similar connectors by the customer.

WARNING

Hot motor housing

Fire hazard

→ Ensure that no combustible or flammable materials are

located close to the fan.

;

Inspect the device for visible external damage and the proper function

of the protective features before switching it on.

;

Check the air flow paths of the fan for foreign objects and remove any

that are found.

;

Apply the nominal voltage to the voltage supply.

4.7 Switching off the device

;

Disconnect the device from the supply voltage at the main switch for

the supply line.

;

When disconnecting, be sure to disconnect the earth wire connection

last.

5. MAINTENANCE, MALFUNCTIONS, POSSIBLE

CAUSES AND REMEDIES

Do not perform any repairs on your device. Return the device to ebm-

papst for repair or replacement.

WARNING

Terminals and connections have voltage even with a

unit that is shut off

Electric shock

→ Wait five minutes after disconnecting the voltage at all poles

before opening the device.

CAUTION

Electrical load on the capacitor after device is switched off

Electric shock, risk of injury

→ Discharge the capacitors before working on the device.

CAUTION

The motor restarts automatically when operating voltage

is applied, e.g. after a power failure.

Danger of injury

→ Keep out of the danger zone of the device.

→ When working on the device, switch off the mains

supply voltage and secure the latter from being switched on

again.

→ Wait until the device stops.

If the device remains out of use for some time, e.g. when in

storage, we recommend switching the device on for at least

two hours to allow any condensate to evaporate and to move

the bearings.

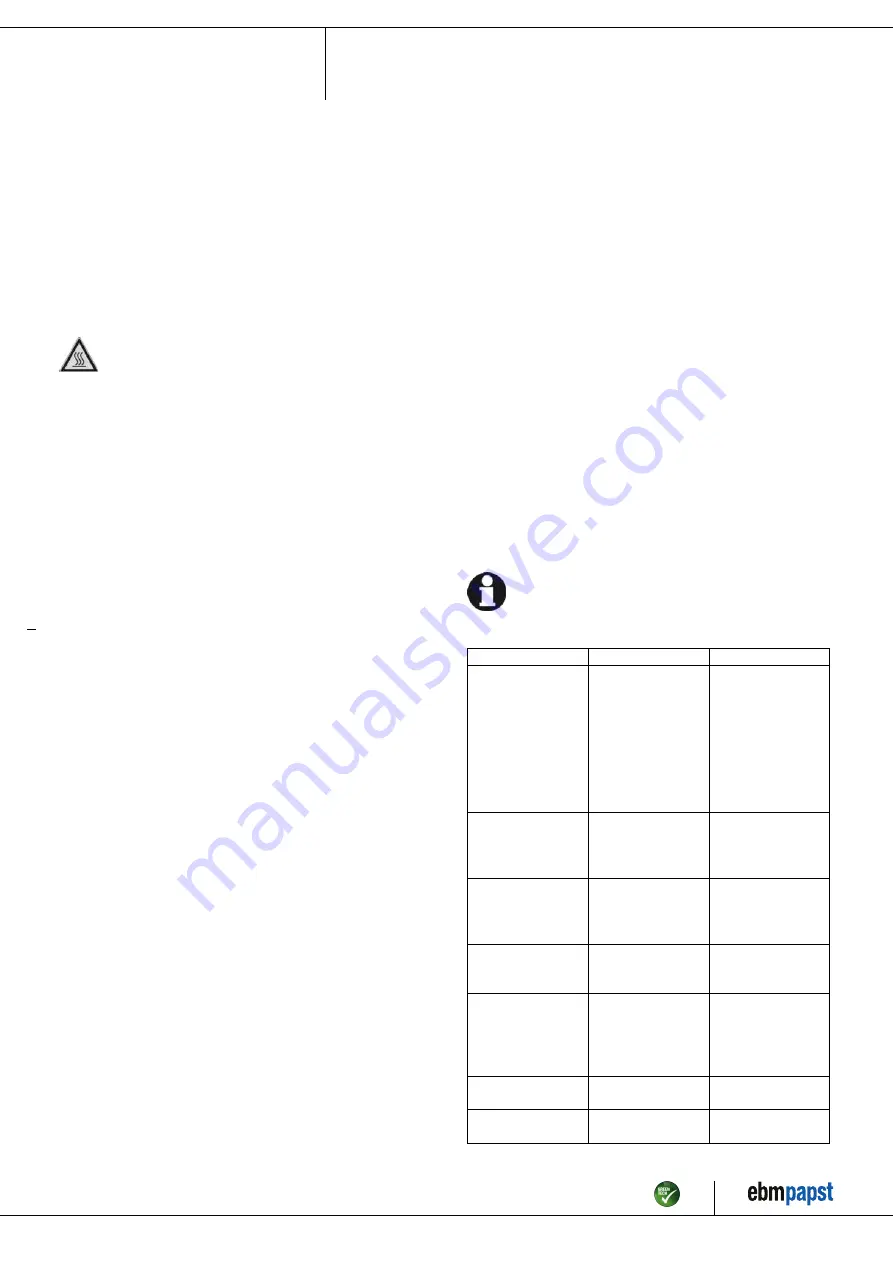

Malfunction/error

Possible cause

Possible remedy

Impeller running

roughly

Imbalance in rotating

parts

Clean the device; if

imbalance is still

evident after cleaning,

replace the device.

If you have

attached any weight

clips during cleaning,

make sure to remove

them afterwards.

Motor does not turn

Mechanical blockage

Switch off, de-

energise, and

remove mechanical

blockage.

Mains supply voltage

faulty

Check mains supply

voltage,

restore power

supply.

Faulty connection

De-energise, correct

connection, see

connection diagram.

Thermal overload

protector responded

Allow motor to cool

off, locate and rectify

cause of error, if

necessary cancel

restart lock-out

Unacceptable

operating point

Check operating point

Overtemperature of

motor

Ambient temperature

too high

Lower ambient

temperature if possible

Item no. 11143-5-9970 · ENG · Revision 84268 · Release 2015-06-23 · Page 8 / 9

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com