Operating instructions

S4D250-CA36-12

Translation of the original operating instructions

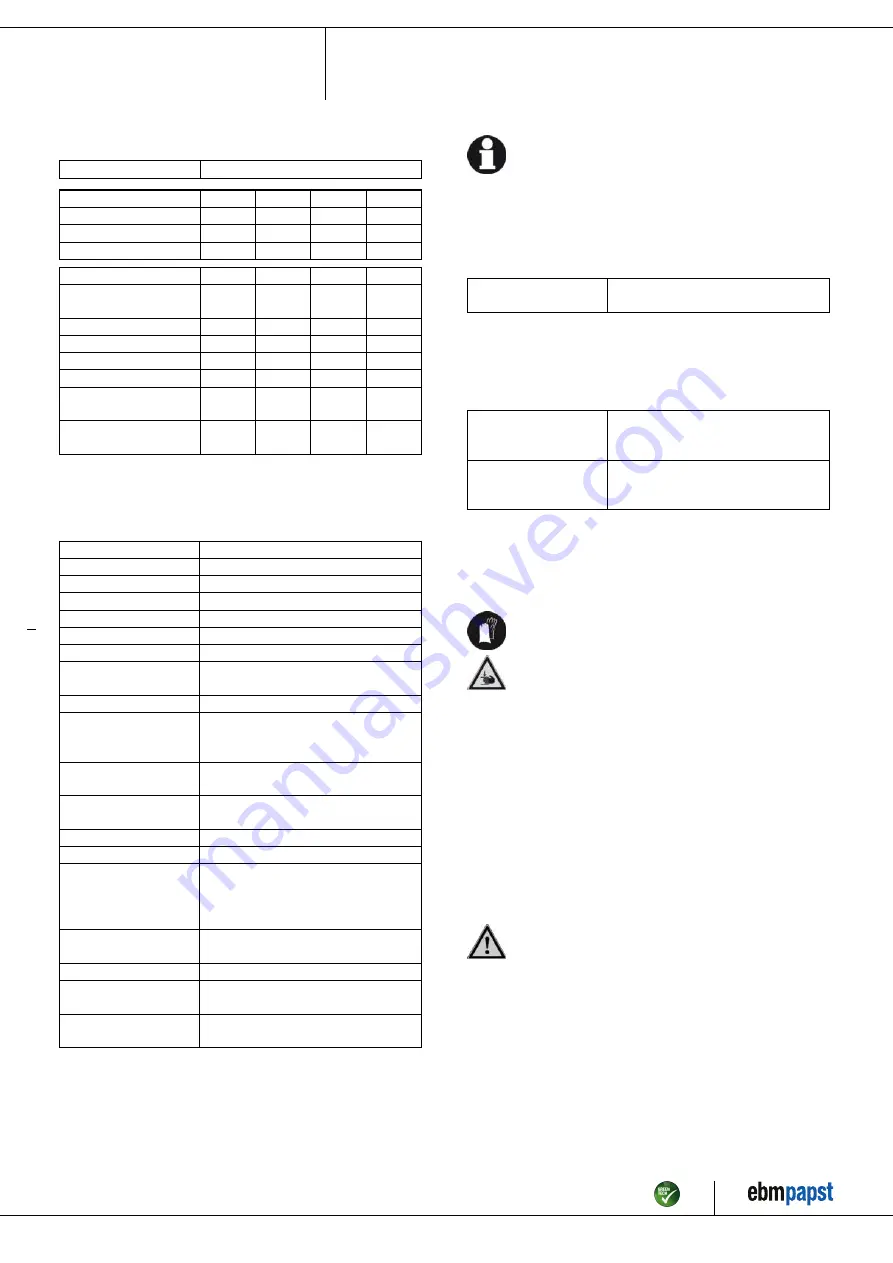

3.2 Nominal data

Motor

M4D068-CF

Phase

3~

3~

3~

3~

Nominal voltage / VAC

230

230

400

400

Connection

Δ

Δ

Y

Y

Frequency / Hz

50

60

50

60

Type of data definition

fa

fa

fa

fa

Valid for approval /

standard

CE

CE

CE

CE

Speed (rpm) / min

-1

1420

1640

1420

1640

Power input / W

27

33

27

33

Current draw / A

0.14

0.12

0.08

0.07

Max. back pressure / Pa

100

110

100

110

Min. ambient

temperature / °C

-25

-25

-25

-25

Max. ambient

temperature / °C

85

85

85

85

ml = Max. load · me = Max. efficiency · fa = Running at free air

cs = Customer specs · cu = Customer unit

Subject to alterations

3.3 Technical features

Mass

1.7 kg

Size

250 mm

Surface of rotor

Coated in black

Material of blades

Sheet steel, coated in black

Material of guard grille

Steel, coated in black plastic (RAL9005)

Direction of air flow

"V"

Direction of rotation

Counter-clockwise, seen on rotor

Type of protection

IP 44; Depending on installation and

position as per EN 60034-5

Insulation class

"B"

Humidity (F)/

environmental

protection class (H)

H0+

Mounting position

Shaft horizontal or rotor on bottom; rotor

on top on request

Condensate discharge

holes

Rotor-side

Operation mode

S1

Motor bearing

Ball bearing

Touch current acc.

IEC 60990 (measuring

network Fig. 4, TN

system)

< 0.75 mA

Motor protection

Thermal overload protector (TOP)

brought out, basic insulation

Cable exit

Lateral

Protection class

I (if protective earth is connected by

customer)

Product conforming

to standard

EN 60335-1; CE

For cyclic speed loads, note that the rotating parts of the device

are designed for maximum one million load cycles. If you have

specific questions, contact ebm-papst for support.

3.4 Mounting data

For depth of screw, see chapter 3.1 Product drawing

;

Secure the mounting screws against accidentally coming loose (e.g.

by using self-locking screws).

Strength class for

mounting screws

8.8

You can obtain additional mounting data from the product drawing if

necessary.

3.5 Transport and storage conditions

;

Use the device in accordance with its protection type.

Max. permissible

ambient motor temp.

(transp./ storage)

+ 80 °C

Min. permissible

ambient motor temp.

(transp./storage)

- 40 °C

4. CONNECTION AND START-UP

4.1 Connecting the mechanical system

CAUTION

Cutting and crushing hazard when removing the fan

from the packaging

→ Carefully remove the device from its packaging, only

touching the guard grille. Make sure to avoid any shock.

→ Wear safety shoes and cut-resistant safety gloves.

NOTE

Damage to device from vibration

Bearing damage, reduced service life

→ Forces or impermissibly high vibration levels must not be

transmitted to the fan from system components. #If the fan is

connected to air ducts, it should isolated from vibrations, for

example using compensators or similar elements. #Fasten

the fan to the substructure without distorting it.

;

Check the device for transport damage. Damaged devices must no

longer be installed.

;

Install the undamaged device according to your application.

CAUTION

Possibility of damage to the device

Serious damage may result if the device slips during assembly.

→ Keep the device fixed in position at the installation location

until all attachment screws have been tightened.

Item no. 15348-5-9970 · ENG · Revision 84873 · Release 2015-06-19 · Page 5 / 10

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com