Operating instructions

S4E300-AS72-30

Translation of the original operating instructions

Unacceptable

operating point

Check operating point

Overtemperature of

motor

Ambient temperature

too high

Lower ambient

temperature if possible

Insufficient cooling

Improve cooling

If you have any other problems, contact ebm-papst.

5.1 Cleaning

NOTE

Damage to the device during cleaning.

Malfunction possible

→ Do not clean the device using a water jet or high-pressure

washer.

→ Do not use any cleaners containing acids,

bases or solvents.

→ Do not use any pointed or sharp-edged objects to clean.

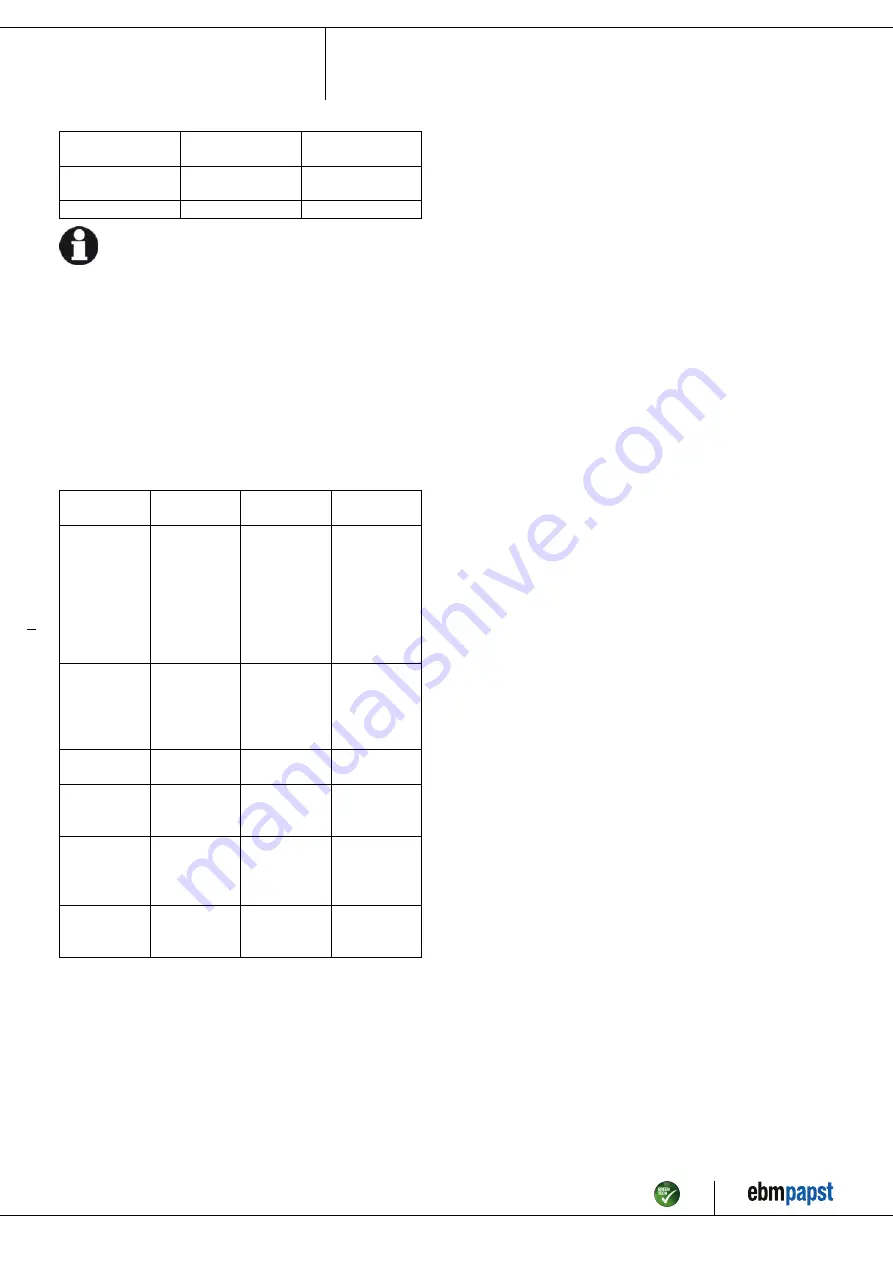

5.2 Safety test

What has to

be tested?

How to test?

Frequency

Which

measure?

Check the

protective

casing against

accidental

contact for

damage and to

ensure that it is

intact

Visual inspection At least every

6 months

Repair or

replacement of

the device

Check the

device for

damage to

blades and

housing

Visual inspection At least every

6 months

Replacement

of the device

Mounting the

connection lines

Visual inspection At least every

6 months

Fasten

Mounting of

protective

earth connection

Visual inspection At least every

6 months

Fasten

Check the

insulation of

the wires for

damage

Visual inspection At least every

6 months

Replace wires

Weld seams

for crack

formation

Visual inspection At least every

6 months

Replace device

Item no. 11024-5-9970 · Revision 79663 · Release 2013-04-23 · Page 9 / 9

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com