Part Number

Operating Instructions

Item no. LS-147

Revision 001

Release 10/04/2017

Page 4 of 10

ebm-papst A&NZ Pty Ltd

10 Oxford Road · Laverton North VIC 3026 · Phone +61 (03) 9360 6400 · Fax +61 (03) 9360 6464

ABN 33 115 927 556

NSW Phone +61 (02) 9827 6400 · NSW Fax +61 (02) 9827 6464 · NZ Phone +64 (09) 525 0245 · NZ Fax +64 (09) 525 0246

sales@ebmpapst.com.au · www.ebmpapst.com.au

S4E500AM03LA-001

3.

TECHNICAL DATA

3.1

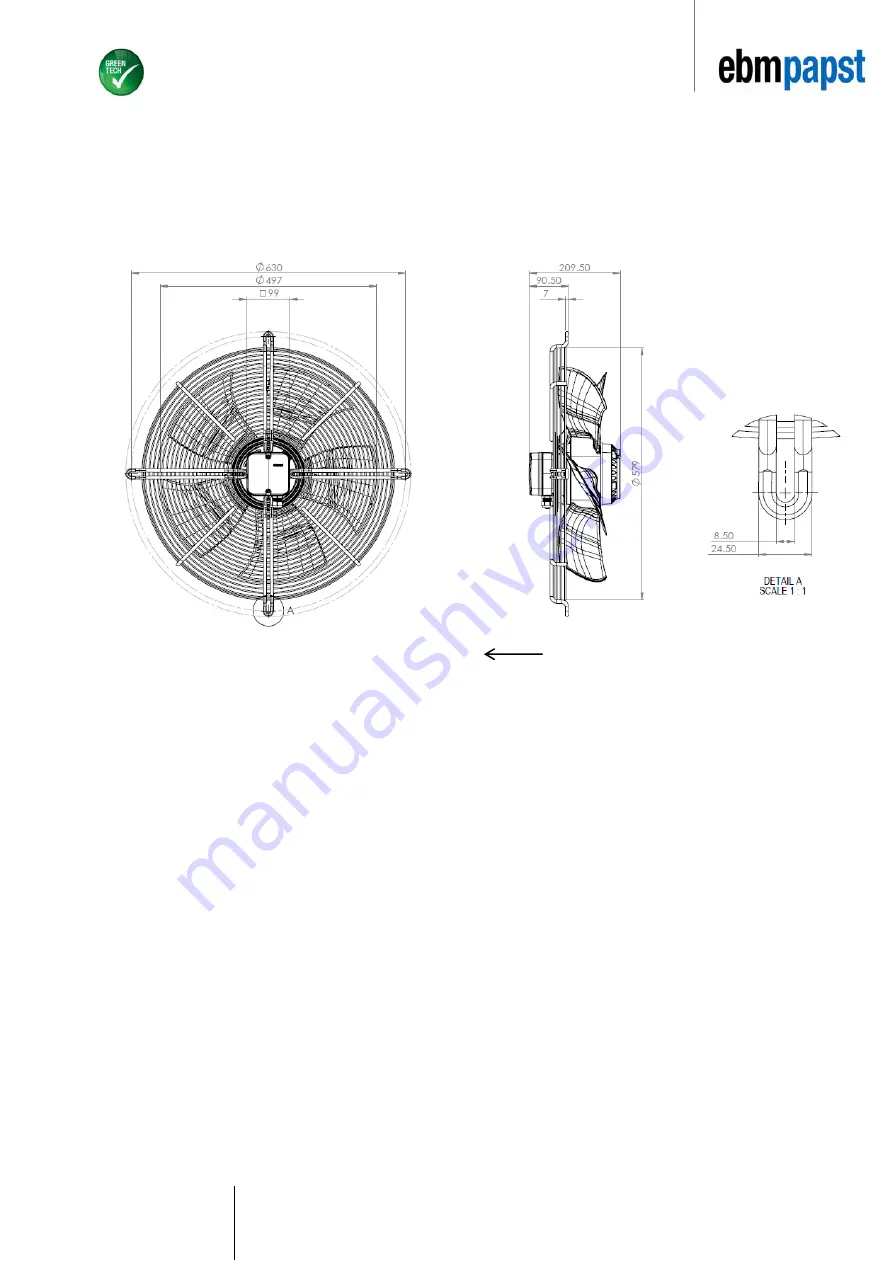

Product drawing

AIRFLOW DIRECTION

All dimensions are in mm

Direction of air flow “V”

Fan cable requirement

Power supply cable diameter: min 6mm, max 12 mm, tightening torque for cable gland 2 ±0.3 Nm.

Fan terminal box requirements

Tightening torque 1.5±0.2 Nm for 2x screws on lid.