Operating instructions

S6D560-AK01-03

Translation of the original operating instructions

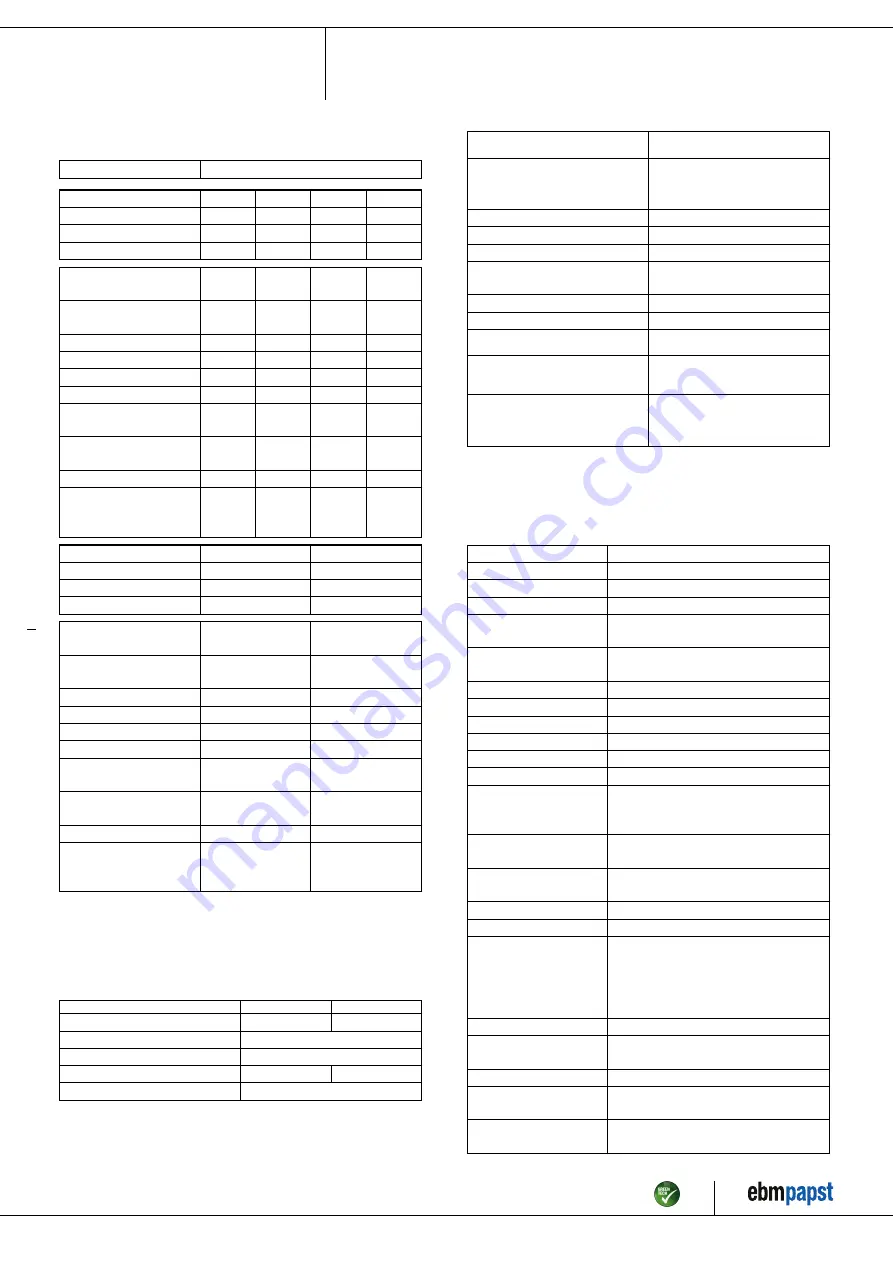

3.2 Nominal data

Motor

M6D110-EF

Phase

3~

3~

3~

3~

Nominal voltage / VAC

230

230

277

400

Wiring

Δ

Δ

Δ

Y

Frequency / Hz

50

60

60

50

Method of obtaining

data

ml

ml

ml

ml

Valid for approval/

standard

CE

CE

CE

CE

Speed (rpm) / min

-1

890

970

1040

890

Power consumption / W

380

550

600

380

Current draw / A

1.35

1.71

1.66

0.78

Max. back pressure / Pa

80

95

110

80

Min. ambient

temperature / °C

-40

-40

-40

-40

Max. ambient

temperature / °C

65

55

55

65

Starting current / A

4.4

4

Max. safe operating

speed (rpm) /

min

-1

1650

@ 70 °C

1650

@ 70 °C

1650

@ 70 °C

1650

@ 70 °C

Phase

3~

3~

Nominal voltage / VAC

400

480

Wiring

Y

Y

Frequency / Hz

60

60

Method of obtaining

data

ml

ml

Valid for approval/

standard

CE

CE

Speed (rpm) / min

-1

970

1040

Power consumption / W

550

600

Current draw / A

0.99

0.96

Max. back pressure / Pa

95

110

Min. ambient

temperature / °C

-40

-40

Max. ambient

temperature / °C

55

55

Starting current / A

Max. safe operating

speed (rpm) /

min

-1

1650

@ 70 °C

1650

@ 70 °C

ml = Max. load · me = Max. efficiency · fa = Free air

cs = Customer specification · ce = Customer equipment

Subject to change

3.3 Data according to Commission Regulation (EU) 327/

2011

Actual

Req. 2015

01 Overall efficiency η

es

/ %

31

31

02 Measurement category

A

03 Efficiency category

Static

04 Efficiency grade N

40

40

05 Variable speed drive

No

06 Year of manufacture

The year of manufacture is specified on the

product's rating label.

07 Manufacturer

ebm-papst Mulfingen GmbH & Co. KG

Amtsgericht (court of registration) Stuttgart

· HRA 590344

D-74673 Mulfingen

08 Type

S6D560-AK01-03

09 Power consumption P

e

/ kW

0.38

09 Air flow q

v

/ m³/h

4805

09 Pressure increase total p

sf

/

Pa

85

10 Speed (rpm) n / min

-1

890

11 Specific ratio

*

1.00

12 Recycling/disposal

Information on recycling and disposal is

provided in the operating instructions.

13 Maintenance

Information on installation, operation and

maintenance is provided in the operating

instructions.

14 Additional components

Components used to calculate the energy

efficiency that are not apparent from the

measurement category are detailed in the

CE declaration.

*

Specific ratio = 1 + p

fs

/ 100 000 Pa

Data obtained at optimum efficiency level. The ErP data is determined using a motor-impeller

combination in a standardized measurement setup.

3.4 Technical description

Weight

12.4 kg

Fan size

560 mm

Rotor surface

Cast in aluminum

Terminal box material

PC/ABS plastic

Blade material

Sheet aluminum insert, sprayed with PP

plastic

Guard grille material

Steel, coated with black plastic (RAL

9005)

Number of blades

5

Blade pitch

-5°

Airflow direction

"V"

Direction of rotation

Counterclockwise, viewed toward rotor

Degree of protection

IP54

Insulation class

"F"

Moisture (F) /

Environmental (H)

protection class

F3-1

Installation position

Shaft horizontal or rotor on bottom; rotor

on top on request

Condensation

drainage holes

On rotor side

Mode

S1

Motor bearing

Ball bearing

Touch current

according to IEC

60990 (measuring

circuit Fig. 4, TN

system)

<= 3.5 mA

Electrical hookup

Via terminal box

Motor protection

Thermal overload protector (TOP) with

basic insulation

with cable

Axial

Protection class

I (with customer connection of protective

earth)

Conformity with

standards

EN 61800-5-1; CE

Item no. 10856-5-9970 · ENU · Change 91583 · Approved 2016-09-23 · Page 5 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com