Operating instructions

8300100068

VBH0500CTTRS

Translation of the original operating instructions

Protection class

assignment

I; If a protective earth is connected by

the customer

This component for installation may

have several local protection classes.

This information relates to this

component’s basic design.

The final protection class is based on

the component’s intended installation and

connection.

Conformity with

standards

EN 61800-5-1; CE; UKCA

Approval

CSA C22.2 No. 77 + CAN/CSA-

E60730-1; EAC; UL 1004-7 + 60730-1

;

Use the device in accordance with its degree of protection.

Information on surface quality

The surfaces of the products conform to the generally applicable industrial

standard. The surface quality may change during the production period.

This has no effect on strength, dimensional stability and dimensional

accuracy.

The color pigments in the paints used perceptibly react to UV light over

the course of time. The product is to be protected against UV radiation to

prevent the formation of patches and fading. Changes in color are not a

reason for complaint and are not covered by the warranty. UV radiation

in the frequency range and the intensity of natural solar radiation has no

effect on the technical properties of the products.

3.5 Mounting data

Further mounting data can be taken from the product drawing or Chapter

4.1 Mechanical connection as required.

Strength class of

screws

8.8

;

Secure the screws against unintentional loosening (e.g. use self-

locking screws).

3.6 Transport and storage conditions

Max. permitted

ambient temp. for

motor (transport/

storage)

+80 °C

Min. permitted

ambient temp. for

motor (transport/

storage)

-40 °C

3.7 Electromagnetic compatibility

If several devices are connected in parallel on the supply side

so that the line current of the arrangement is in the range 16 - 75

A, this arrangement conforms to IEC 61000-3-12, provided that

the short-circuit power S

sc at the connection point of the

customer system to the public power grid is greater than or

equal to 250 times the rated output of the arrangement. It is the

responsibility of the installation engineer or operator/owner of the

device to ensure, if necessary after consultation with the

network operator, that this device is only connected to a

connection point with an S

sc value greater than or equal to 250

times the rated output of the arrangement.

4. CONNECTION AND STARTUP

4.1 Mechanical connection

CAUTION

Risk of cutting and crushing when removing device

from packaging

→ Carefully remove the device from the packaging by grasping

hold of the frame. Never subject to any impact.

→ Wear safety shoes and cut-resistant safety gloves.

NOTE

Damage to the device from vibration

Bearing damage, shorter service life

→ The fan must not be subjected to force or excessive vibration

from sections of the installation.

→ If the fan is connected to air ducts, the connection should

be isolated from vibration, e.g. using compensators or similar

elements.

→ Ensure stress-free attachment of the fan to the

substructure.

;

The fan may not be handled in the area around the inlet nozzle during

transport and installation.

There is a risk of damage to the impeller.

;

Check the device for transport damage. Damaged devices are not to

be installed.

;

Install the undamaged device in accordance with your application.

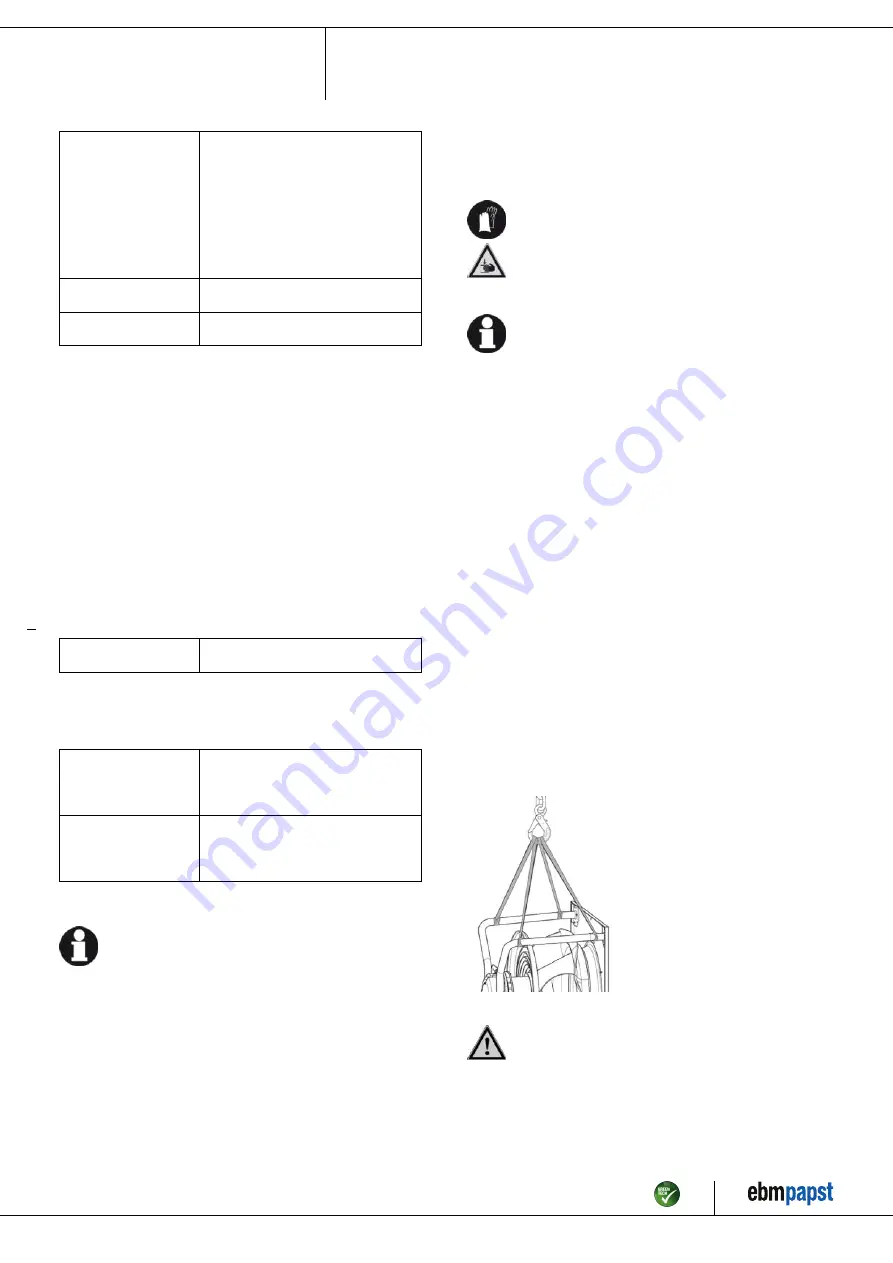

4.1.1 Installation of RadiPac fan

Use is always to be made of appropriate hoisting equipment and a

suitable lifting device when transporting the fan for installation purposes.

Only suitable round slings are to be used for this purpose (see Chapter

3.4 Technical description for weight of product). Use four round slings

passed around the struts for lashing purposes. Position the round slings

as shown in the hoisting diagram below. Make sure that the struts of the

support bracket on the left and right of the motor are vertical. During

installation, only transport the fan in the installation position as shown in

the product drawing. Heed the information given on the device! During

transportation, an acceleration of 2 g must not be exceeded.

Fig. 1: Hoisting diagram for transportation of RadiPac

CAUTION

Possible damage to the device

If the device slips during installation, serious damage can result.

→ Ensure that the device is securely positioned at its place of

installation until all fastening screws have been tightened.

●

The fan must not be strained on fastening.

Item no. 1170000679 · ENU · Change 275056 · Approved 2023-01-27 · Page 6 / 16

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com