Operating instructions

W1G250-HJ87-02

Translation of the original operating instructions

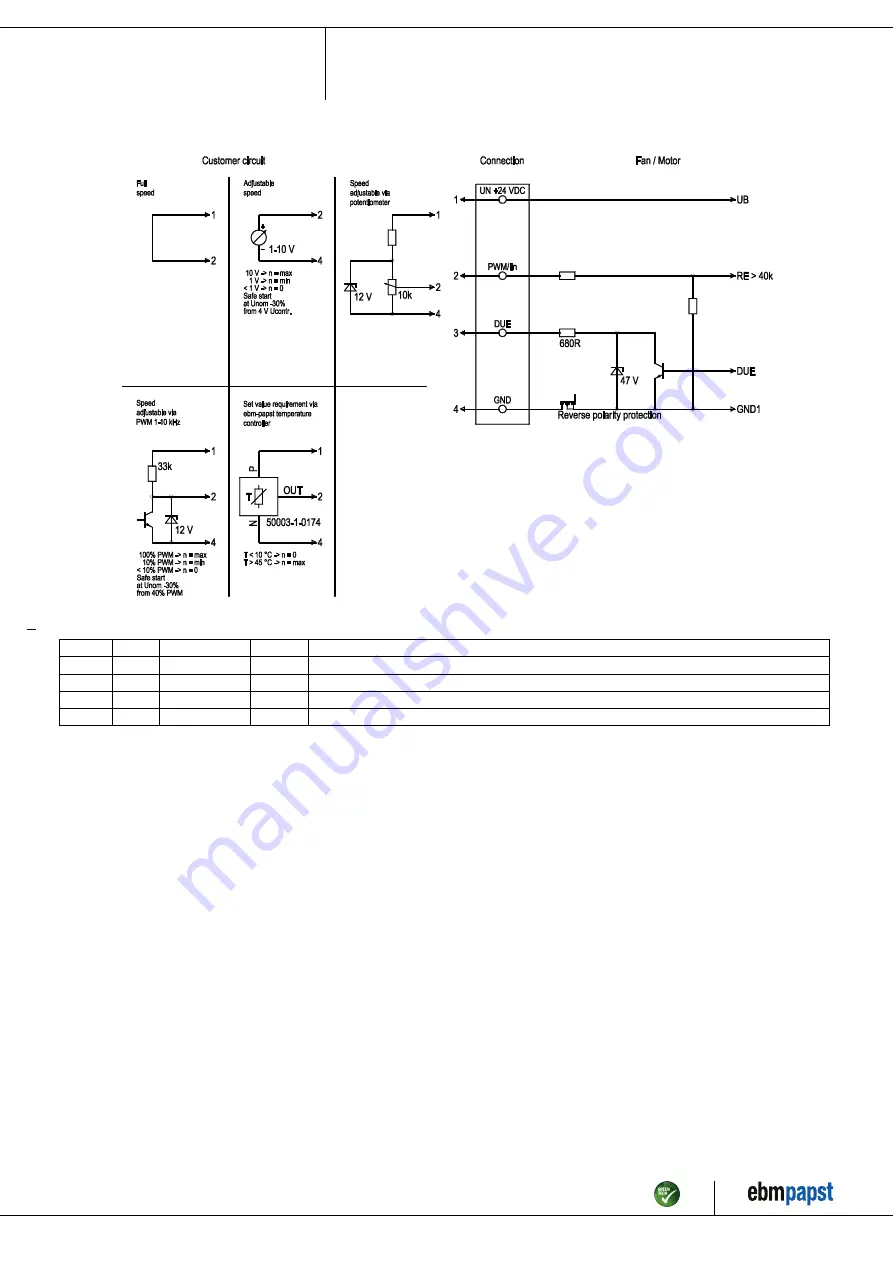

4.4 Connection diagram

Drawing preliminary!

No.

Conn.

Designation

Color

Function/assignment

1

UN +24 VDC

red

Power supply 24 VDC, maximum ripple 3.5%

2

PWM/LIN

yellow

Control input Re > 40k

3

DUE

white

Tach output, 3 pulses per revolution, Isink max = 10 mA

4

GND

blue

Reference ground

Item no. 54137-5-9970 · ENU · Change 99077 · Approved 2018-03-13 · Page 7 / 9

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com