Operating instructions

W2E250-HJ28-09

Translation of the original operating instructions

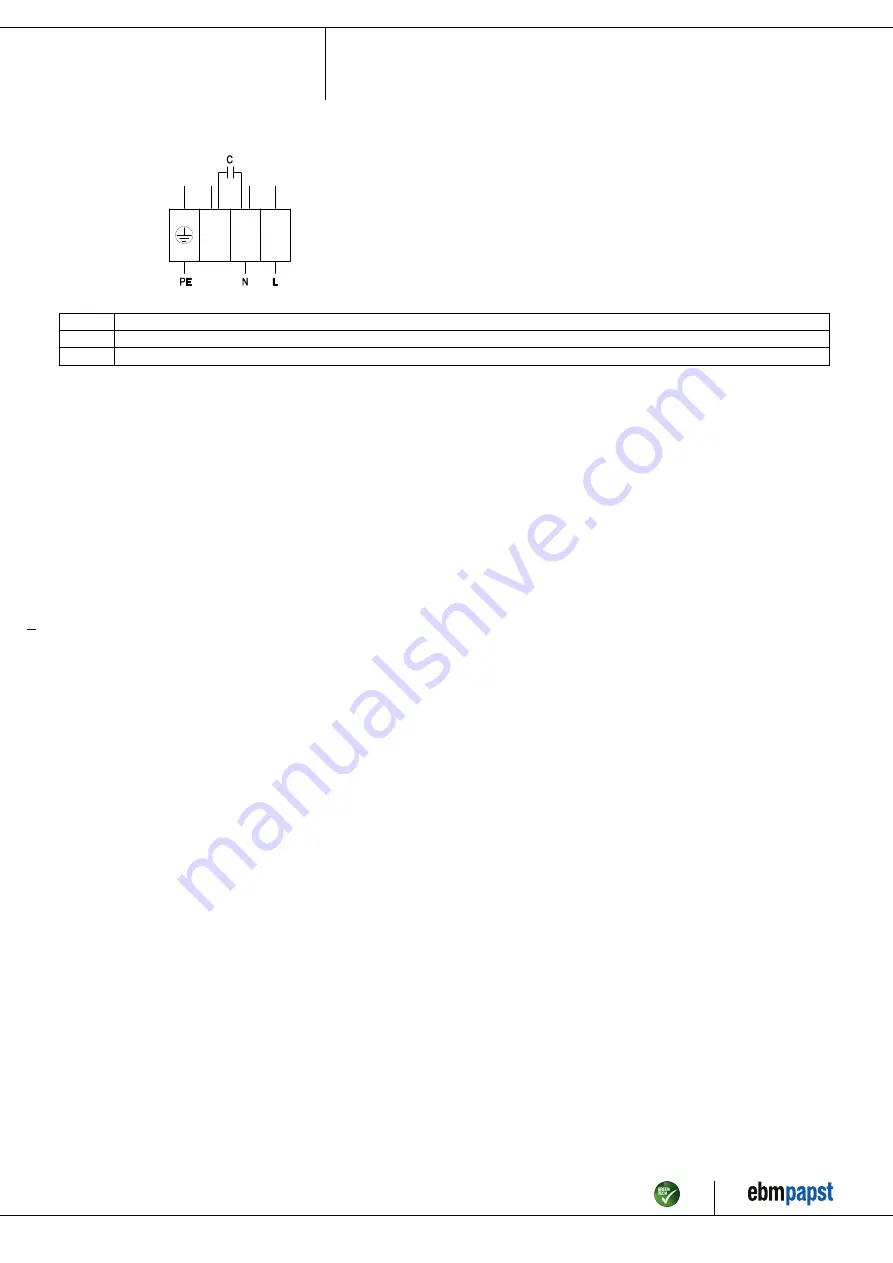

4.4 Connection diagram

PE

green/yellow

N

black

L

blue

Item no. 12087-5-9970 · ENU · Change 201834 · Approved 2019-01-17 · Page 8 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com