Operating instructions

W3G300-JK13-30

Translation of the original operating instructions

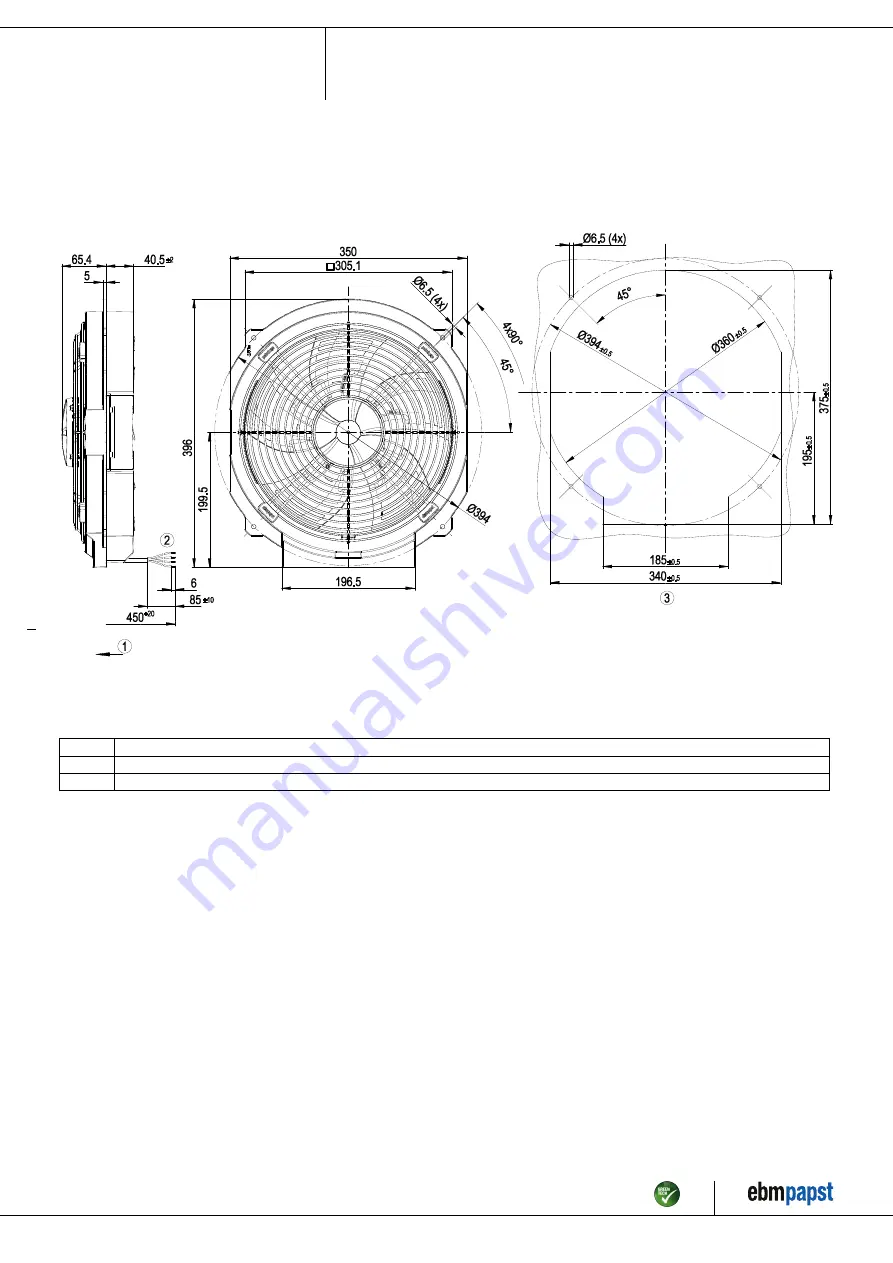

3. TECHNICAL DATA

3.1 Product drawing

All dimensions in mm.

1

Direction of air flow "V"

2

Cable PVC AWG20, 4x crimped splices

3

Mounting dimensions

Item no. 52105-5-9970 · ENU · Change 202174 · Approved 2019-01-04 · Page 4 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com