Operating instructions

W3G300-UL11-35

Translation of the original operating instructions

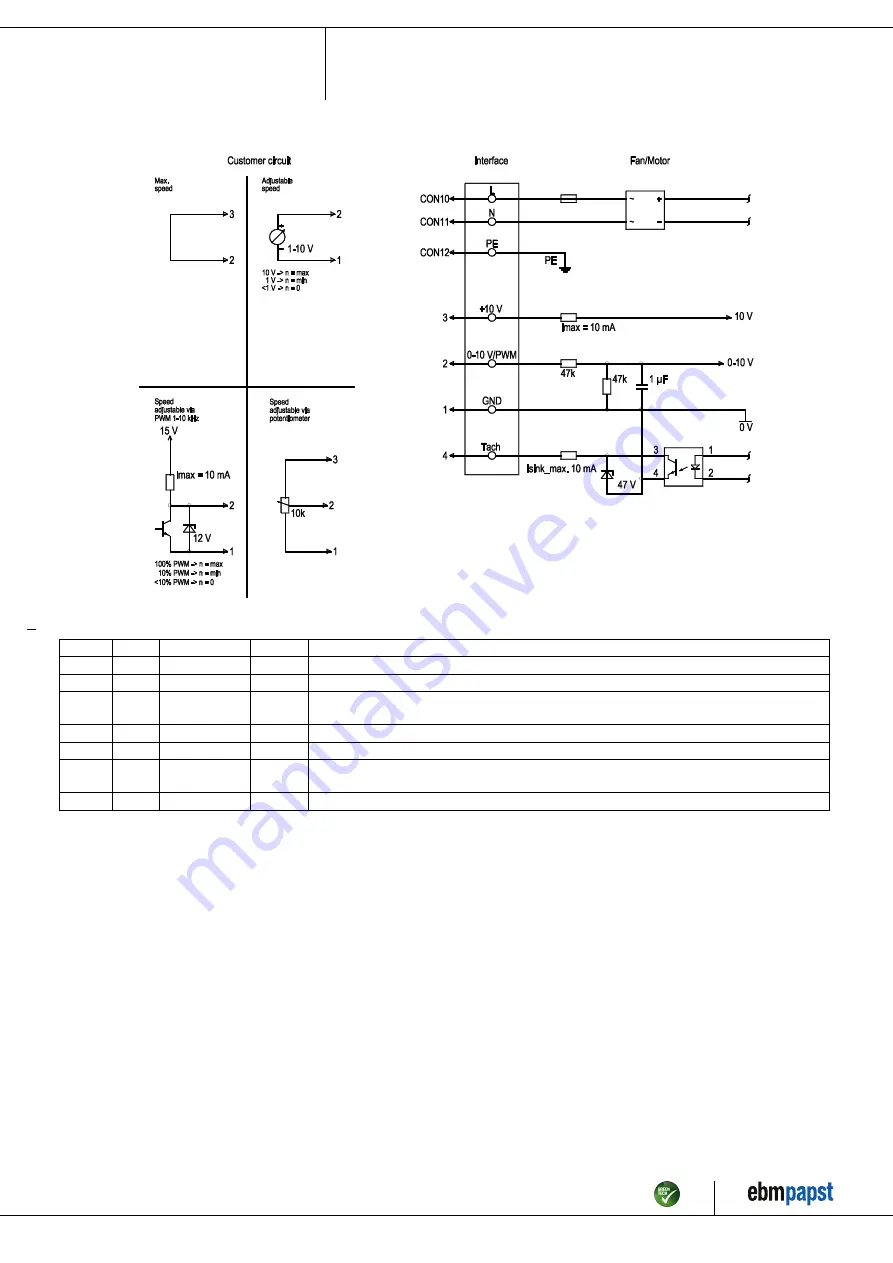

4.4 Connection diagram

Drawing preliminary!

No.

Conn.

Designation

Color

Function/assignment

CON10 L

black

Supply connection, power supply, phase, see nameplate for voltage range

CON11 N

blue

Supply connection, power supply, neutral conductor, see nameplate for voltage range

CON12 PE

green/

yellow

Ground connection

2

0- 10V PWM

yellow

0-10 V / PWM control input, Ri=100 kΩ, SELV

4

Tach

white

Tach output, open collector, 1 pulse per revolution, Isink max = 10 mA, SELV

3

+10 V

red

Fixed voltage output 10 VDC +/-3 %, Imax. 10 mA, short-circuit-proof, power supply for ext.

devices (e.g. pot), SELV

1

GND

blue

Reference ground for control interface, SELV

Item no. 56443-5-9970 · ENU · Change 204765 · Approved 2019-06-25 · Page 8 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com