Operating instructions

W3G385-CT65-81

Translation of the original operating instructions

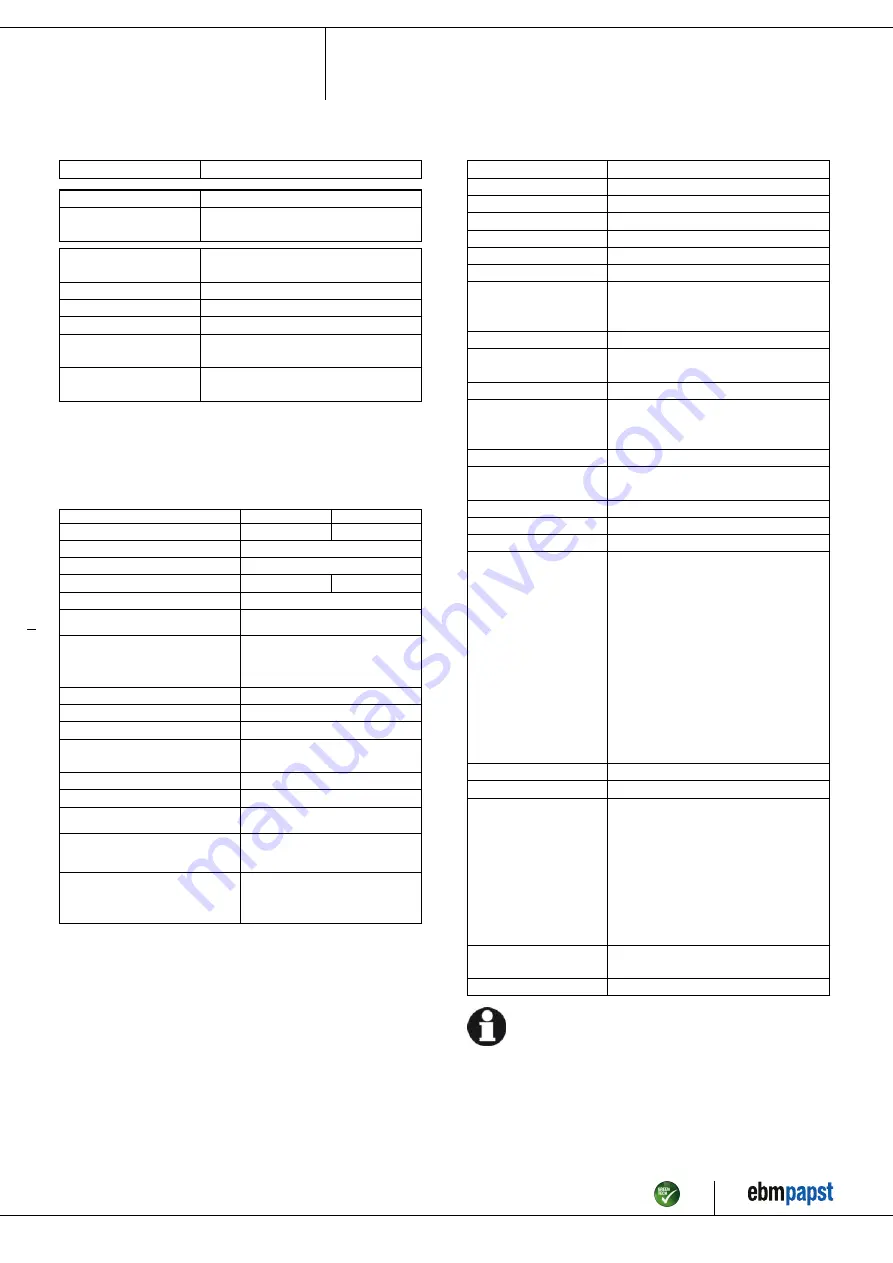

3.2 Nominal data

Motor

M3G084-CF

Nominal voltage / VDC

26

Nominal voltage

range / VDC

16 .. 32

Method of obtaining

data

fa

Speed (rpm) / min

-1

3140

Power consumption / W

450

Current draw / A

17.7

Min. ambient

temperature / °C

-40

Max. ambient

temperature / °C

70

ml = Max. load · me = Max. efficiency · fa = Free air

cs = Customer specification · ce = Customer equipment

Subject to change

3.3 Data according to Commission Regulation (EU) 327/

2011

Actual

Req. 2015

01 Overall efficiency η

es

/ %

44.7

32.3

02 Measurement category

A

03 Efficiency category

Static

04 Efficiency grade N

52.4

40

05 Variable speed drive

Yes

06 Year of manufacture

The year of manufacture is specified on the

product's rating label.

07 Manufacturer

ebm-papst Mulfingen GmbH & Co. KG

Amtsgericht (court of registration) Stuttgart ·

HRA 590344

D-74673 Mulfingen

08 Type

W3G385-CT65-81

09 Power consumption P

e

/ kW

0.61

09 Air flow q

v

/ m³/h

2705

09 Pressure increase total p

fs

/

Pa

329

10 Speed (rpm) n / min

-1

3065

11 Specific ratio

*

1.00

12 Recycling/disposal

Information on recycling and disposal is

provided in the operating instructions.

13 Maintenance

Information on installation, operation and

maintenance is provided in the operating

instructions.

14 Additional components

Components used to calculate the energy

efficiency that are not apparent from the

measurement category are detailed in the

CE declaration.

*

Specific ratio = 1 + p

fs

/ 100 000 Pa

Data obtained at optimum efficiency level. The efficiency values displayed for achieving

conformity with the Ecodesign Regulation EU 327/2011 has been reached with defined air

duct components (e.g. inlet rings). The dimensions must be requested from ebm-papst. If

other air conduction geometries are used on the installation side, the ebm-papst evaluation

loses its validity/the conformity must be confirmed again. The product does not fall within

the scope of Regulation (EU) 2019/1781 due to the exception specified in Article 2 (2a)

(motors completely integrated into a product).

3.4 Technical description

Weight

3.1 kg

Size

385 mm

Motor size

84

Blade material

PA plastic UL94 V0

Fan housing material

PA plastic UL94 V0

Number of blades

7

Airflow direction

V

Balancing grade

according to DIN ISO

21940-11

G 10

Direction of rotation

Clockwise, viewed toward rotor

Degree of protection

Motor IP24 KM, electronics IP6K9K

(mating connector installed)

Insulation class

"B"

Moisture (F) /

Environmental (H)

protection class

H3

Installation position

Any

Condensation

drainage holes

None, open rotor

Mode

S1

Motor bearing

Ball bearing; (sealed)

Life expectancy

40,000 h (typical)

Technical features

- Fault output (high-side switch max. 30

mA)

- Power limiter

- Load dump (58 V)

- Motor current limitation

- Soft start

- Control input 0-10 VDC / PWM

- Temperature derating

- Overvoltage detection

- Thermal overload protection for

electronics

- Undervoltage detection

- Reverse polarity protection

Electrical hookup

Standby current less than 500 µA

with cable

Lateral

Protection class

assignment

III; Requires supply with safety extra-

low voltage SELV.

This component for installation may

have several local protection classes.

This information relates to this

component’s basic design.

The final protection class is based on

the component’s intended installation and

connection.

Conformity with

standards

EN 45545-2, HL3; EN 50155; EN

61373, Cat. 1B; CE

Approval

EAC

With regard to cyclic speed loads, note that the rotating parts of

the device are designed for a maximum of one million load

cycles. If you have special questions, consult ebm-papst for

support.

;

Use the device in accordance with its degree of protection.

Item no. 53117-5-9970 · ENU · Change 231712 · Approved 2021-11-11 · Page 5 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com