Operating instructions

W3G450-ZI07-H1

Translation of the original operating instructions

NOTE

Tightness and strain relief are dependent on the cable

used.

→ This must be checked by the user.

4.3.2 Connecting wires to terminals

WARNING

Live terminals and connections even with device

switched off

Electric shock

→ Wait five minutes after disconnecting the voltage at all poles

before opening the device.

;

Remove the cap from the cable gland.

Only remove caps where cables are fed in.

;

Route the wire(s) (not included in scope of delivery) into the terminal

box.

;

First connect the "PE" (protective earth).

;

Connect the wires to the corresponding terminals.

Use a screwdriver to do so.

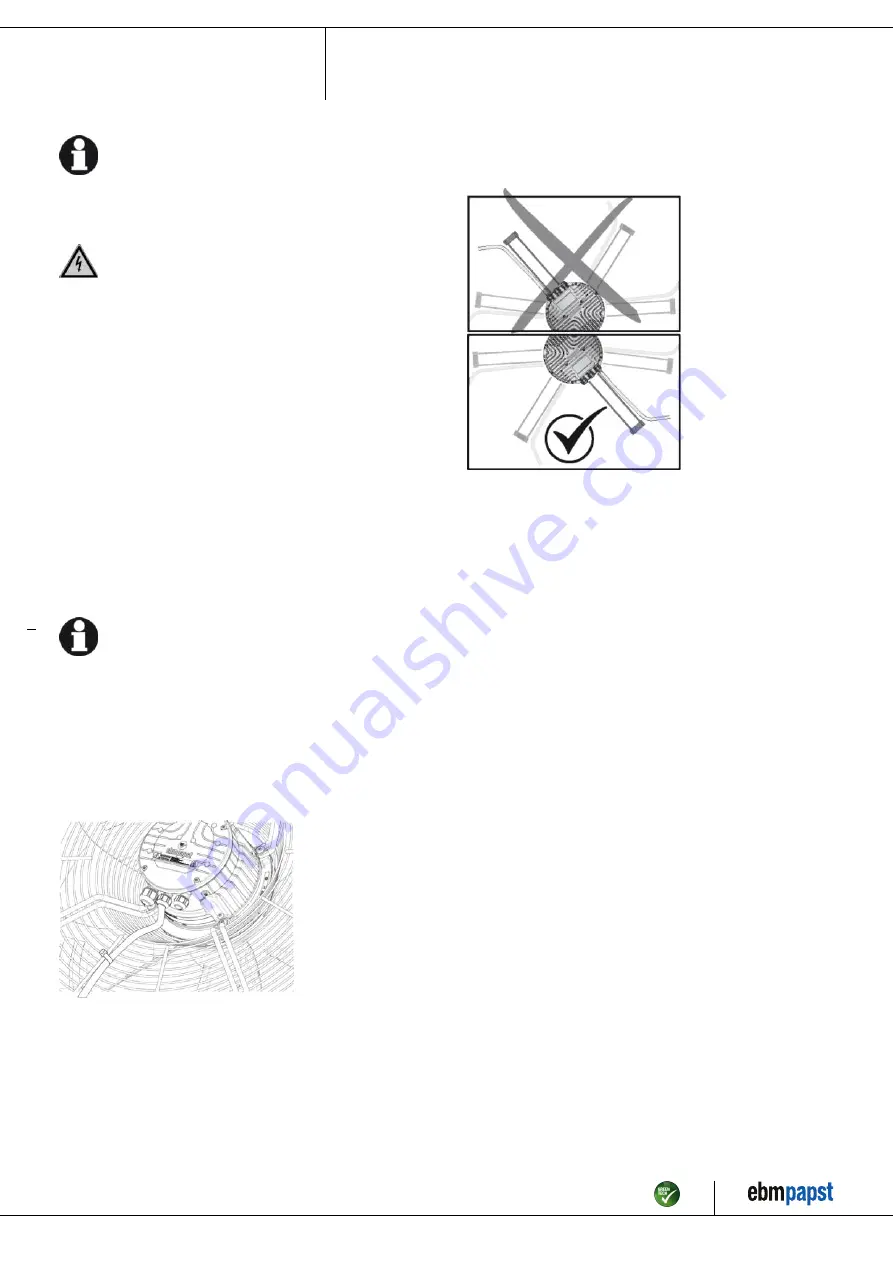

When connecting, ensure that no wire ends fan out.

;

Seal the terminal box.

;

Fit the terminal box cover so that the arrow points towards the cable

glands.

4.3.3 Cable routing

Water must be prevented from reaching the cable gland along the cable.

NOTE

Damage caused by moisture penetration.

Moisture can penetrate into the terminal box if water is

constantly present at the cable glands.

→ To prevent the constant accumulation of water at the cable

glands, the cable should be routed in a U-shaped loop

wherever possible.

→ If this is not possible, a drip edge can be produced by

fitting a cable tie directly in front of the cable gland for example.

Fans installed lying flat

Make sure the cable is routed in a U-shaped loop.

Fig. 2: Fan installed lying flat, cable routed in a U-shaped loop.

Fans installed upright

When routing the cable, make sure that the cable glands are located at

the bottom. The cables must always be routed downward.

Fig. 3: Cable routing for fans installed upright.

Item no. 57958-5-9970 · ENU · Change 244915 · Approved 2022-01-12 · Page 10 / 14

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com