Part Number

Operating Instructions

Item no. LS-105.

Revision 003

Release 30/06/2017

Page 7 of 12

ebm-papst A&NZ Pty Ltd

10 Oxford Road · Laverton North VIC 3026 · Phone +61 (03) 9360 6400 · Fax +61 (03) 9360 6464

ABN 33 115 927 556

NSW Phone +61 (02) 9827 6400 · NSW Fax +61 (02) 9827 6464 · NZ Phone +64 (09) 525 0245 · NZ Fax +64 (09) 525 0246

sales@ebmpapst.com.au · www.ebmpapst.com.au

W3G500GN3307-LA1

4.2.3

Reactive currents

Because of the EMC filter integrated for compliance

with EMC limits (interference emission and

interference immunity), reactive currents can be

measured in the supply line even when the motor is

at a standstill and the mains voltage is switched on.

The values are typically < 250 mA.

At the same time, the effective power in this operating

state (operational readiness) is typically < 5 W.

4.2.4

Residual current circuit breaks (RCCB)

Only universal (type B or B+) residual current devices

(RCD) are permitted. Like frequency inverters, RCD

protective devices cannot provide personal safety while

operating the device. When switching on the power

supply of the device, pulsed charge currents from the

capacitors in the integrated EMC filter can lead to the

RCD protective devices tripping without delay. We

recommend residual current devices with a trigger

threshold of 300 mA and delayed tripping (super-

resistant, characteristic K).

4.2.5

Leakage current

For asymmetrical power systems or of a phase fails, the

leakage current can increase to a multiple of the

nominal value.

4.2.6

Locked rotor protection

Due to the locked-rotor protection, the start-up current

(LRA) is equal to or less than the nominal current (FLA).

4.3

Connection in terminal box

4.3.1

Preparing cables for the connection

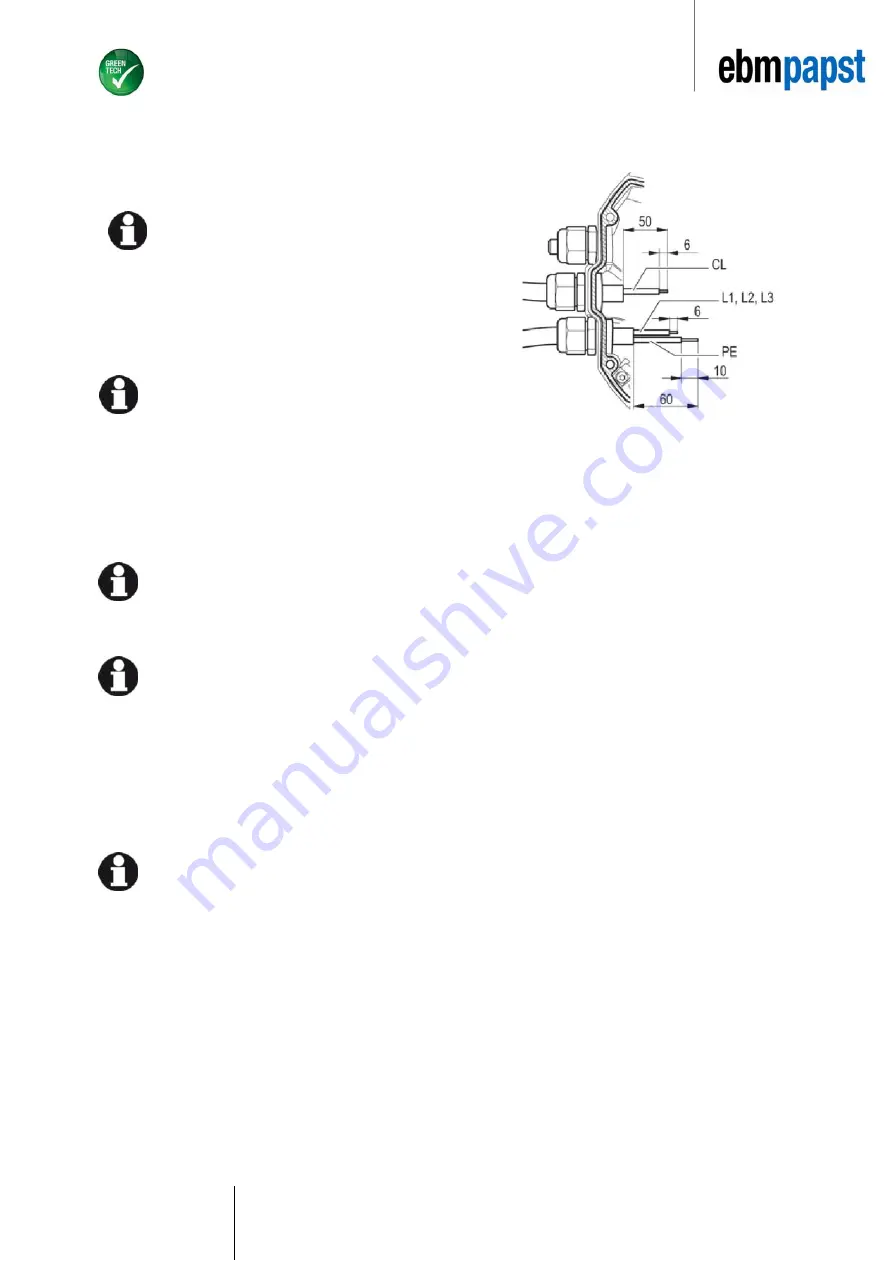

Only strip the cable as far as necessary, ensuring that the

screwed cable gland is sealed and there is no strain on the

connections. For tightening torque, see chapter 3.1 Product

drawing.

NOTE

Tightness and strain relief are dependent on the cable

used.

→ This must be checked by the user.

Fig. 1: Recommended stripping lengths in mm (inside

the terminal box).

Legend: CL = control lines